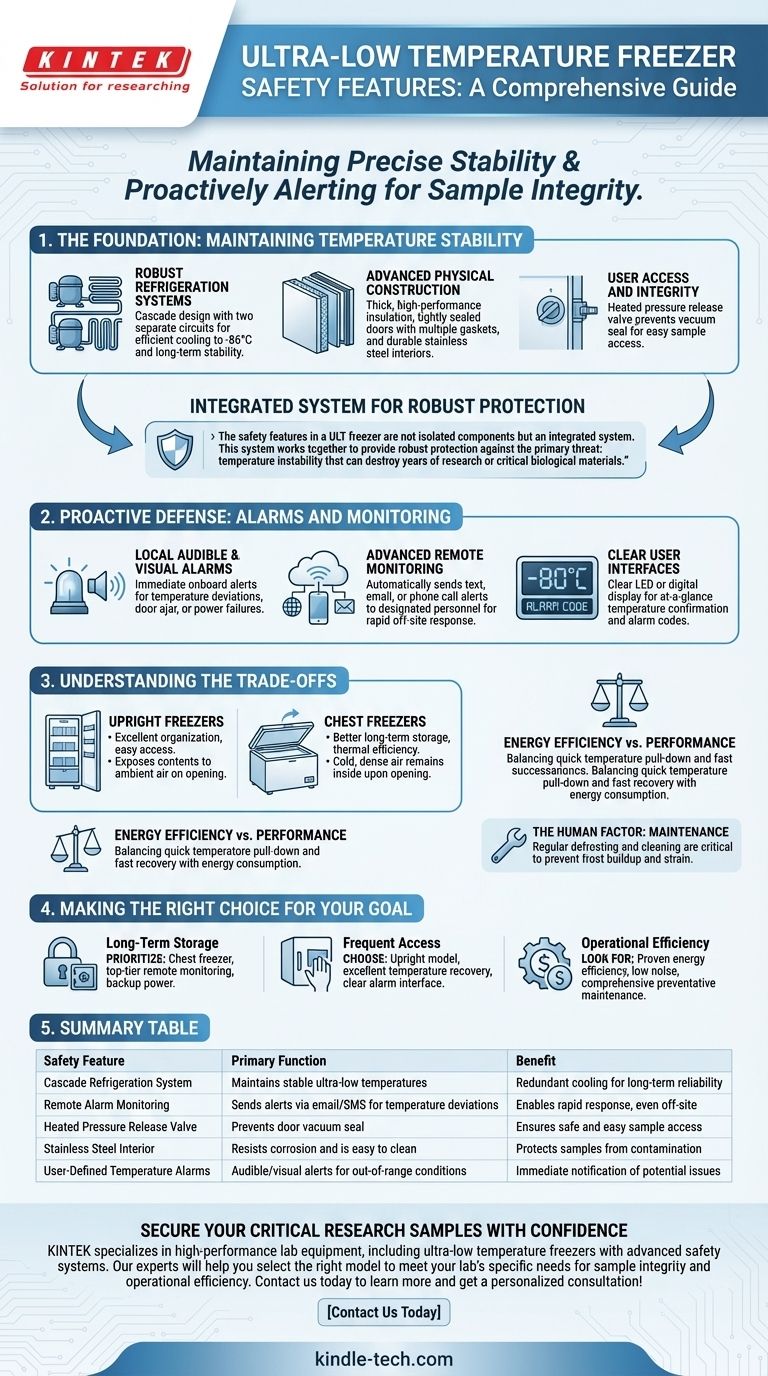

At their core, ultra-low temperature (ULT) freezers are designed with a multi-layered safety system focused on two critical functions: maintaining precise temperature stability and proactively alerting users to any deviation. The most common safety features are sophisticated alarm systems that provide audible, visual, and often remote notifications for temperature fluctuations, door-ajar events, or power failures, ensuring the integrity of invaluable samples.

The safety features in a ULT freezer are not isolated components but an integrated system. This system works together to provide robust protection against the primary threat: temperature instability that can destroy years of research or critical biological materials.

The Foundation: Maintaining Temperature Stability

Before a freezer can alert you to a problem, it must be engineered to prevent one. The most fundamental safety features are built into the freezer's core design to ensure consistent, reliable operation.

Robust Refrigeration Systems

The engine of a ULT freezer is its cascade refrigeration system. This design uses two separate cooling circuits working in tandem to efficiently reach and maintain temperatures as low as -86°C. This redundancy provides a stable foundation for long-term storage.

Advanced Physical Construction

A freezer's physical build is its first line of defense. This includes thick, high-performance insulation and tightly sealed doors with multiple gaskets to minimize heat transfer and reduce frost formation.

Most ULT freezers feature durable stainless steel interiors, which are easy to clean and resist corrosion, protecting samples from contamination.

User Access and Integrity

A seemingly simple but critical feature is the heated pressure release valve. This prevents the vacuum that naturally forms at extreme cold from sealing the door shut, ensuring you can always access your samples when needed without a struggle that could damage the door seal.

Proactive Defense: Alarms and Monitoring

While robust construction prevents many issues, active monitoring is essential for catching failures before they become catastrophic. This is the most visible layer of a ULT freezer's safety net.

Local Audible and Visual Alarms

Nearly all ULT freezers are equipped with onboard alarm systems. These provide immediate, loud audible alerts and flashing visual indicators on the display panel if the internal temperature goes outside a user-defined range.

Advanced Remote Monitoring

Modern laboratories rely on remote alarm systems. These connect the freezer to a network, automatically sending text, email, or phone call alerts to designated personnel in the event of a failure. This ensures a rapid response, even if no one is physically present in the lab.

Clear User Interfaces

A clear LED or digital display is a crucial safety feature. It provides an at-a-glance confirmation of the internal temperature and displays specific alarm codes, helping users quickly diagnose the nature of a problem, whether it's a power outage or a component failure.

Understanding the Trade-offs

Selecting the right safety features involves understanding key design choices and their implications for your specific application.

Upright vs. Chest Freezers

Upright freezers offer excellent organization and easy access to frequently used samples. However, opening the door exposes all contents to ambient air.

Chest freezers are better for long-term storage. When the lid is opened, the cold, dense air tends to remain inside, resulting in less temperature fluctuation and greater thermal efficiency.

Energy Efficiency vs. Performance

Powerful cooling systems consume significant energy. Manufacturers often balance performance features like quick temperature pull-down (rapidly cooling new samples) and fast temperature recovery (after a door opening) with energy efficiency. Prioritizing one may mean a compromise on the other.

The Human Factor: Maintenance

No safety feature can overcome a lack of proper maintenance. Regular defrosting and cleaning are critical to prevent frost buildup, which can compromise door seals and strain the cooling system, ultimately leading to failure.

Making the Right Choice for Your Goal

The ideal set of safety features depends entirely on the value of your samples and your lab's workflow.

- If your primary focus is irreplaceable long-term storage: Prioritize a chest freezer with a top-tier remote monitoring system and a backup power plan.

- If your primary focus is frequent sample access for daily research: Choose an upright model with excellent temperature recovery rates and a clear, intuitive alarm interface.

- If your primary focus is operational efficiency and budget: Look for models with proven energy efficiency, low noise levels, and a comprehensive preventative maintenance plan included in the warranty.

Ultimately, understanding these safety systems empowers you to select and operate a ULT freezer that serves as a secure vault for your most critical assets.

Summary Table:

| Safety Feature | Primary Function | Benefit |

|---|---|---|

| Cascade Refrigeration System | Maintains stable ultra-low temperatures | Redundant cooling for long-term reliability |

| Remote Alarm Monitoring | Sends alerts via email/SMS for temperature deviations | Enables rapid response, even off-site |

| Heated Pressure Release Valve | Prevents door vacuum seal | Ensures safe and easy sample access |

| Stainless Steel Interior | Resists corrosion and is easy to clean | Protects samples from contamination |

| User-Defined Temperature Alarms | Audible/visual alerts for out-of-range conditions | Immediate notification of potential issues |

Secure your critical research samples with confidence. KINTEK specializes in high-performance lab equipment, including ultra-low temperature freezers with advanced safety systems. Our experts will help you select the right model to meet your lab's specific needs for sample integrity and operational efficiency. Contact us today to learn more and get a personalized consultation!

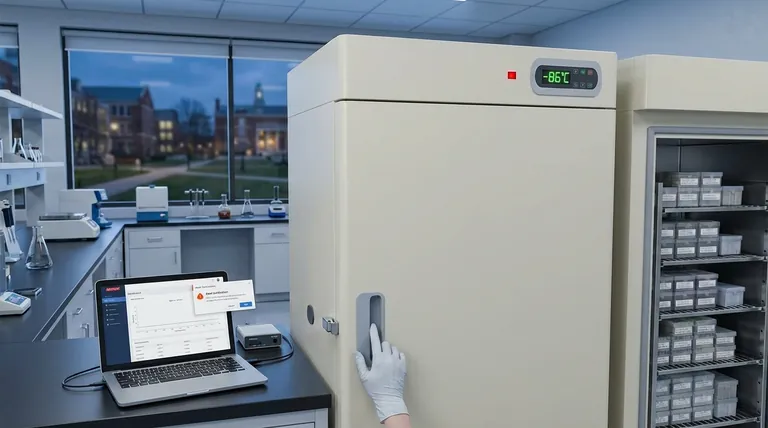

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 108L Vertical Ultra Low Temperature ULT Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- What is convection-based cooling in ultra-low temperature freezers? Achieve Superior Temperature Stability for Your Samples

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation

- Why are ultra-low temperature freezers important in scientific research? Ensure Sample Integrity and Reproducibility