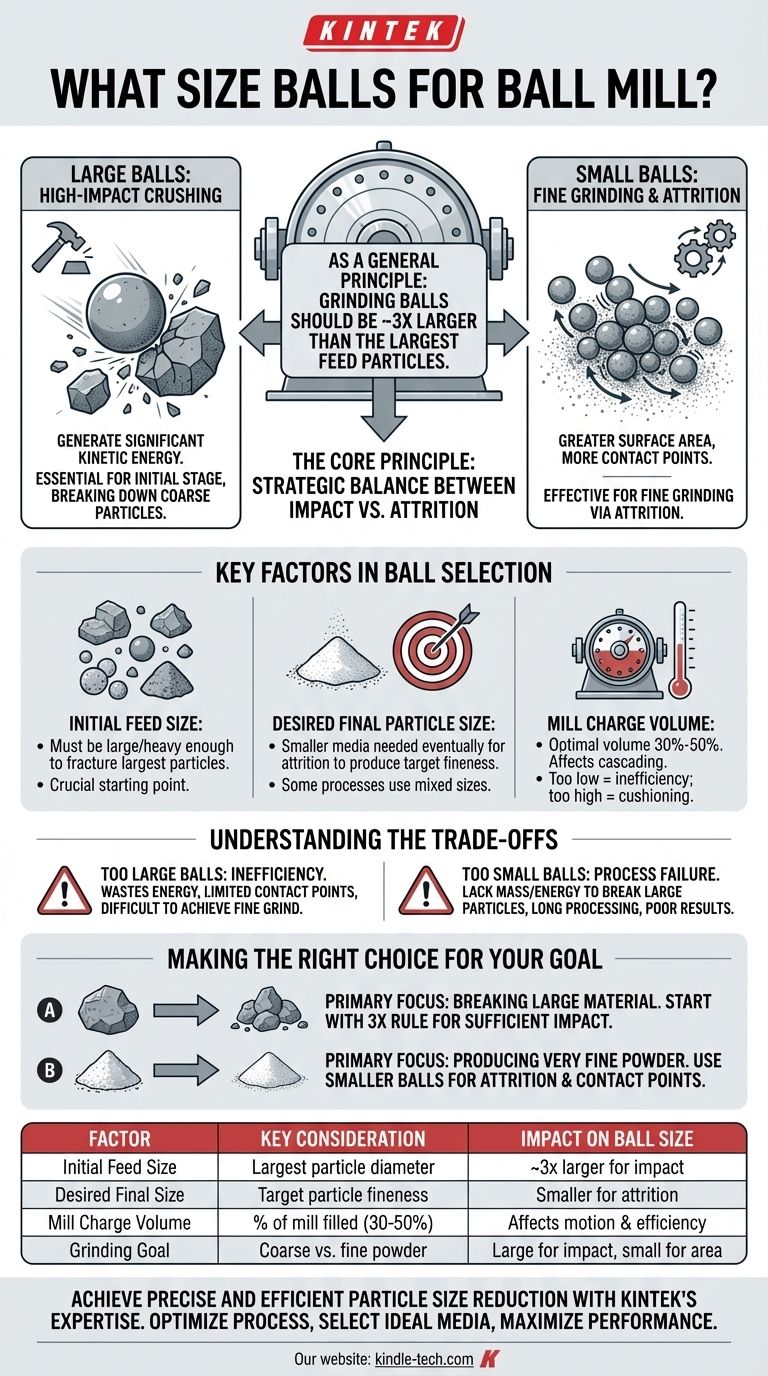

As a general principle, the grinding balls in a ball mill should be approximately three times larger than the largest particles of the material you intend to grind. This serves as a critical starting point for ensuring effective size reduction.

Choosing the correct ball size is a strategic balance between impact force and attrition. Large balls provide the impact needed to break coarse particles, while small balls provide the surface area required for fine grinding.

The Core Principle: Impact vs. Attrition

The primary function of grinding balls is to reduce particle size through two distinct mechanisms. The size of the balls you choose directly determines which mechanism will dominate your process.

Large Balls for High-Impact Crushing

Larger, heavier balls generate significant kinetic energy as they cascade inside the mill. This high-impact force is essential for the initial stage of grinding.

It is this crushing action that effectively breaks down the largest and coarsest particles in your feed material. The "3x rule" is derived from this need for sufficient impact.

Small Balls for Fine Grinding and Attrition

Smaller balls have a much greater collective surface area and create far more contact points within the mill.

This increases the effect of attrition—the rubbing and shearing action between the balls—which is highly effective for grinding already small particles into a very fine powder.

Key Factors in Ball Selection

While the "3x rule" is a reliable starting point, a truly optimized process considers the entire scope of the operation, from the raw material to the final product.

Initial Feed Size

This is the most critical factor. The grinding media must be large and heavy enough to fracture the largest particles in your starting sample. If the balls are too small, they will not possess the energy to initiate size reduction.

Desired Final Particle Size

Your end goal dictates the later stages of grinding. If you need an extremely fine powder, you will eventually need smaller grinding media to maximize attrition and produce the target particle size efficiently. Some processes even use a mix of ball sizes to handle a wider range of particles simultaneously.

Mill Charge Volume

The volume of the mill occupied by the balls—known as the charge volume—is also crucial. It should typically be between 30% and 50%.

An optimal charge volume ensures the balls cascade correctly. Too low a volume reduces grinding efficiency, while too high a volume can cushion the impacts and hinder the process.

Understanding the Trade-offs

Selecting the wrong ball size is one of the most common sources of inefficiency in ball milling operations.

The Problem with Balls That Are Too Large

If your grinding balls are excessively large for the material, the primary issue is inefficiency. You waste energy, and the limited number of contact points makes it very difficult to achieve a fine grind.

The Problem with Balls That Are Too Small

If the balls are too small for the initial feed, the process may fail entirely. The balls will lack the necessary mass and impact energy to break the larger particles, leading to extremely long processing times with poor results.

Making the Right Choice for Your Goal

Your selection should be a direct reflection of your specific size-reduction objective.

- If your primary focus is breaking down large, coarse material: Start with the rule of thumb—select balls approximately 3x larger than your biggest particles to ensure sufficient impact.

- If your primary focus is producing a very fine powder from smaller feed: Use smaller balls to maximize the points of contact and promote efficient grinding through attrition.

Matching your grinding media to your material's specific needs is the key to achieving efficient and repeatable results.

Summary Table:

| Factor | Key Consideration | Impact on Ball Size |

|---|---|---|

| Initial Feed Size | Largest particle diameter | Balls should be ~3x larger for effective impact |

| Desired Final Size | Target particle fineness | Smaller balls are better for fine grinding via attrition |

| Mill Charge Volume | Percentage of mill filled (30-50% optimal) | Affects cascading motion and grinding efficiency |

| Grinding Goal | Coarse crushing vs. fine powder production | Large balls for impact; small balls for surface area |

Achieve precise and efficient particle size reduction with KINTEK's expertise.

Selecting the correct grinding balls is critical for your lab's productivity and the quality of your final product. KINTEK specializes in high-quality lab equipment and consumables, including a wide range of grinding media tailored for various applications.

Our experts can help you:

- Optimize your milling process for faster results and lower energy consumption.

- Select the ideal grinding media (material and size) for your specific material and target particle size.

- Maximize the lifespan and performance of your ball mill.

Don't let inefficient grinding slow down your research or production. Contact KINTEK today for a personalized consultation and let us help you perfect your size-reduction process.

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Hybrid High Energy Vibratory Ball Mill for Lab Use

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

People Also Ask

- What is the role of an agate mortar and pestle in preparing sulfur and iron oxide mixtures? Ensure Purity in Research

- What types of contamination and changes in composition can occur during crushing and grinding? Protect Your Sample Integrity

- How does ball milling equipment influence powder metallurgy? Master Superalloy Preparation & Precision Modeling

- What is a grinder used for in a laboratory? Achieve Accurate & Homogeneous Sample Prep

- What is the principle of colloidal mill in pharmaceutical engineering? Achieve Stable Emulsions & Homogeneous Suspensions

- What is the technical purpose of using a light ball mill for CuW30 powder? Achieve Perfect Particle Dispersion

- What are the advantages of a hammer mill? Versatile, Simple, and Precise Particle Size Control

- How do laboratory pulverizers contribute to finished Ag/Ce-Mn catalysts? Maximize Surface Area and Catalytic Activity