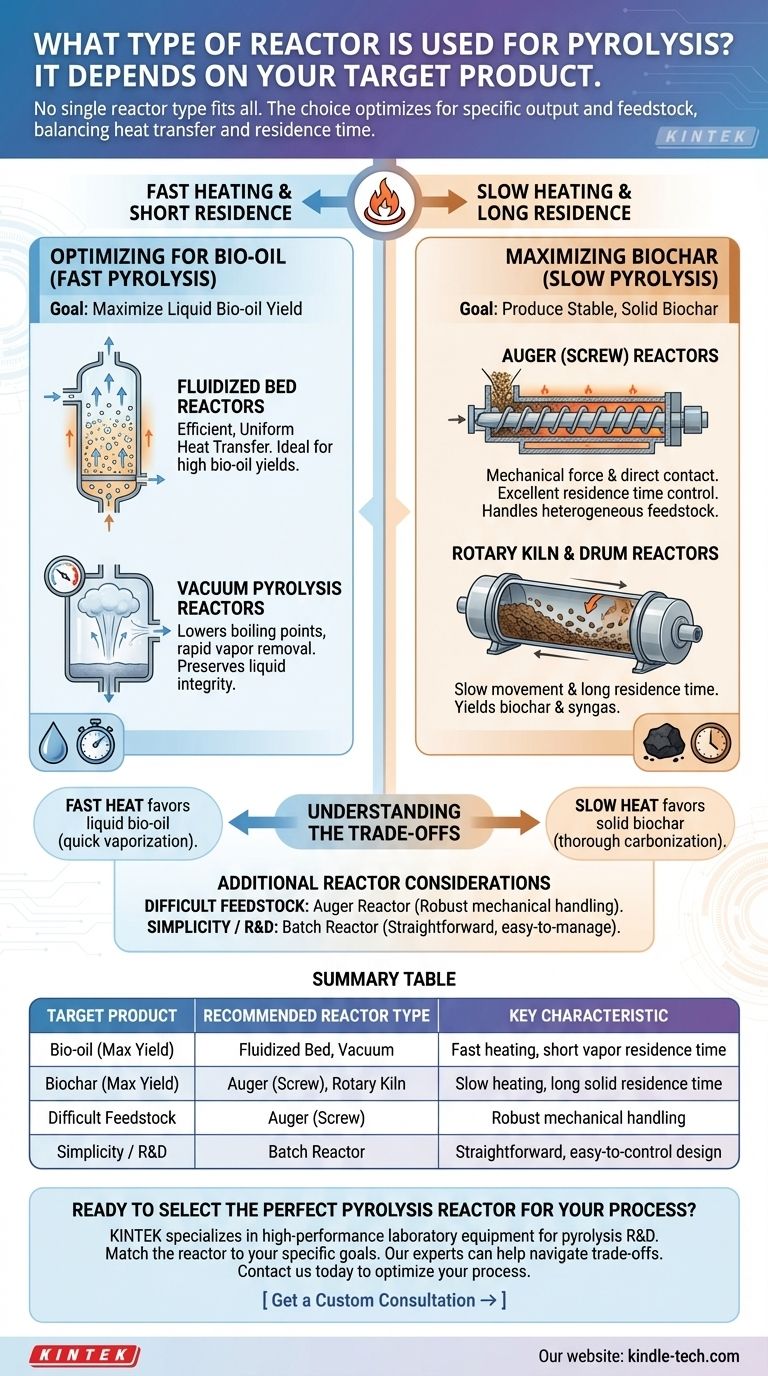

While there is no single type of reactor for pyrolysis, the most common industrial choices are fluidized bed reactors and rotary kiln reactors. The specific reactor selected depends entirely on the type of feedstock being processed and, more importantly, the desired primary product—whether that be bio-oil, biochar, or synthesis gas.

The central decision in selecting a pyrolysis reactor is not about finding the "best" technology, but about matching the reactor's method of heat transfer and material residence time to your target output. Fast heating favors liquid bio-oil, while slow heating maximizes solid biochar.

Optimizing for Bio-oil (Fast Pyrolysis)

To maximize the yield of liquid bio-oil, the pyrolysis process must be fast, with very rapid heating rates and short residence times for the resulting vapors. This minimizes secondary cracking of the valuable organic compounds.

Fluidized Bed Reactors

A fluidized bed reactor is the leading choice for high bio-oil yields. It works by suspending the solid feedstock particles in an upward-flowing stream of hot gas, creating a "fluidized" bed that behaves like a liquid.

This design provides extremely efficient and uniform heat transfer, which is the critical requirement for fast pyrolysis. Circulating fluidized bed (CFB) reactors are an advanced version that further enhances this efficiency, making them ideal for large-scale bio-oil production.

Vacuum Pyrolysis Reactors

Operating the pyrolysis process under a vacuum is another effective technique. By lowering the pressure, the boiling points of the organic compounds are reduced, allowing them to be vaporized and removed from the reactor quickly.

This rapid removal helps preserve the integrity of the liquid products, preventing them from breaking down into non-condensable gases and char.

Maximizing Biochar (Slow Pyrolysis)

If the primary goal is producing stable, solid biochar, the process requires slow heating rates and long residence times. This allows the biomass to thoroughly carbonize.

Auger (Screw) Reactors

An auger reactor, also known as a screw reactor, uses a large screw mechanism to transport feedstock through a heated chamber. The process relies on mechanical force and direct contact for heat transfer.

This design provides excellent control over residence time and is less focused on rapid heating. As a result, it is highly effective for slow pyrolysis, where the main product is biochar. It is generally not the preferred choice for producing bio-oils.

Rotary Kiln and Drum Reactors

A rotary kiln or drum reactor consists of a large, rotating cylindrical vessel, often slightly inclined. As the drum rotates, the feedstock tumbles and slowly moves through the heated zone.

The slow movement and long residence time are well-suited for slow pyrolysis. This process yields a significant amount of biochar as well as gaseous byproducts like syngas, which can be captured and used for energy.

Understanding the Trade-offs

The choice of a reactor technology is a direct trade-off between its operational characteristics and the desired product slate. No single reactor excels at producing all outputs equally.

Fast Heat vs. Slow Heat

The rate of heat transfer is the single most important variable. Fluidized beds excel at fast heating, which vaporizes the biomass quickly to produce condensable liquids (bio-oil). Auger and rotary reactors provide slower, more controlled heating, allowing the carbon structure to form and maximizing solid biochar.

Feedstock Handling

Some reactors are better suited for specific types of materials. An auger reactor is particularly valuable for handling heterogeneous or difficult feedstocks (like sludges or mixed plastics) because its mechanical screw can reliably move and process non-uniform material.

Simplicity and Scale

A batch reactor is the simplest design—essentially a sealed container that is heated. While not continuous, its simplicity and energy stability make it a viable option for smaller-scale operations or research where precise control over a single batch is needed.

Making the Right Choice for Your Goal

Your selection should be guided by your primary objective.

- If your primary focus is high-yield bio-oil production: Choose a fluidized bed reactor for its superior heat transfer and efficiency in fast pyrolysis.

- If your primary focus is maximizing biochar output: Choose an auger (screw) reactor or a rotary drum reactor for their controlled, slow heating and long residence times.

- If your primary focus is processing difficult or mixed feedstock: Choose an auger reactor for its robust mechanical handling capabilities.

- If your primary focus is operational simplicity or small-scale testing: Choose a batch reactor for its straightforward and easy-to-manage design.

Ultimately, understanding your target product is the first and most critical step in selecting the right pyrolysis reactor technology.

Summary Table:

| Target Product | Recommended Reactor Type | Key Characteristic |

|---|---|---|

| Bio-oil (Max Yield) | Fluidized Bed, Vacuum | Fast heating, short vapor residence time |

| Biochar (Max Yield) | Auger (Screw), Rotary Kiln | Slow heating, long solid residence time |

| Difficult Feedstock | Auger (Screw) | Robust mechanical handling |

| Simplicity / R&D | Batch Reactor | Straightforward, easy-to-control design |

Ready to Select the Perfect Pyrolysis Reactor for Your Process?

Choosing the right reactor technology is critical to achieving your target yields of bio-oil, biochar, or syngas. KINTEK specializes in supplying high-performance laboratory equipment, including reactors tailored for pyrolysis research and development.

We understand that matching the reactor to your specific feedstock and product goals is the key to success. Our experts can help you navigate the trade-offs between heat transfer, residence time, and scalability.

Contact us today to discuss your project requirements and discover how KINTEK's solutions can optimize your pyrolysis process.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success