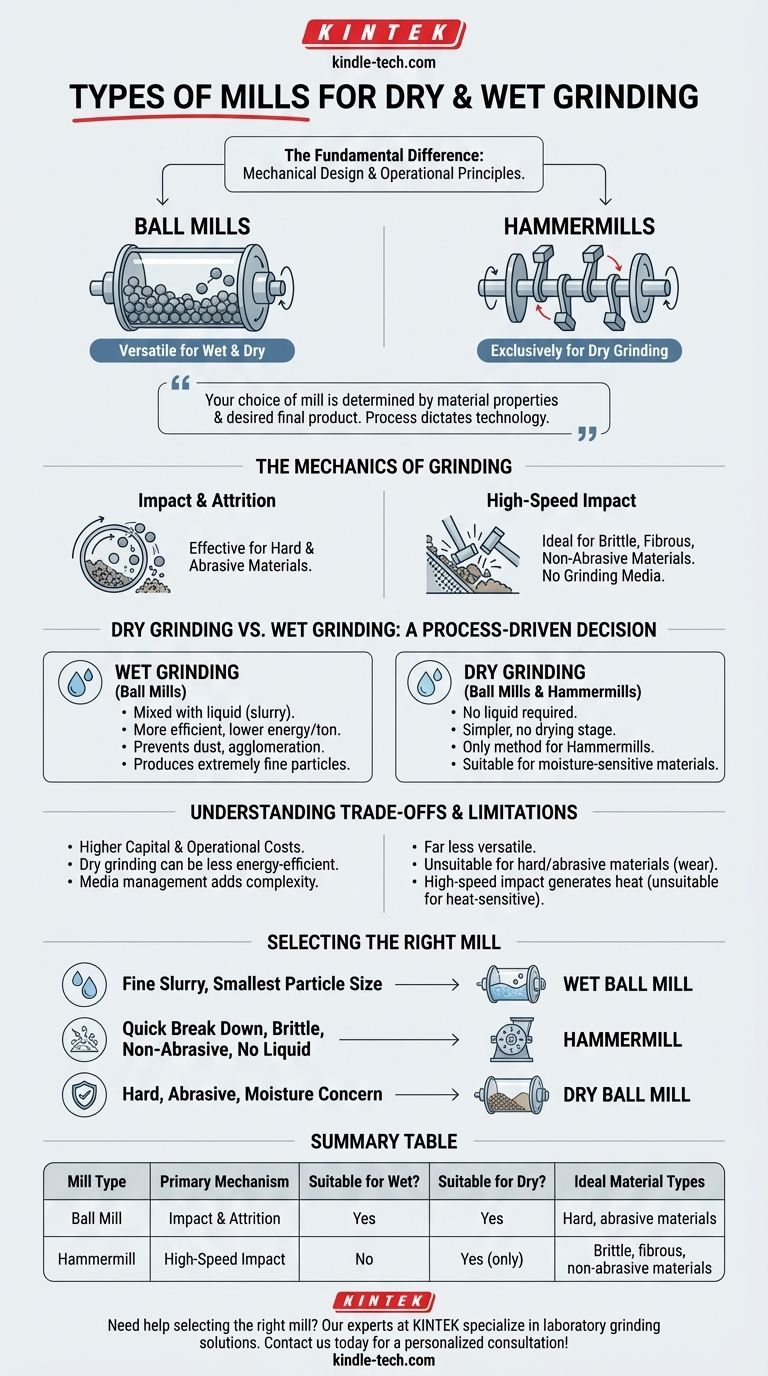

The fundamental difference between mills used for dry and wet grinding lies in their mechanical design and operational principles. Ball mills are highly versatile and can be engineered for both wet and dry grinding processes. In contrast, hammermills are designed exclusively for dry grinding, typically for softer, non-abrasive materials.

Your choice of mill is ultimately determined by your material's properties and your desired final product. The decision between a wet or dry process dictates the technology, not the other way around.

The Mechanics of Grinding: Impact vs. Attrition

To understand which mill to use, you must first understand how each one works. The grinding method—the way a mill applies force—is the most critical factor.

Ball Mills: Grinding Through Impact and Attrition

A ball mill is a rotating cylindrical drum partially filled with grinding media, such as steel or ceramic balls.

As the drum rotates, the media is lifted up the side and then tumbles down, crushing the material through two primary forces: impact and attrition (rubbing).

This dual-action mechanism makes ball mills extremely effective for grinding hard and abrasive materials down to a very fine powder.

Hammermills: Grinding Through High-Speed Impact

A hammermill uses a series of swinging hammers attached to a high-speed rotating shaft.

Material is fed into the chamber and shattered by the repeated, high-velocity blows from the hammers until it is small enough to pass through a screen.

This method relies purely on high-impact force, making it ideal for brittle, fibrous, or less abrasive materials. It does not use grinding media.

Dry Grinding vs. Wet Grinding: A Process-Driven Decision

The choice to use a liquid in the grinding process fundamentally changes the operational dynamics and is a key factor in selecting the right equipment.

Why Choose Wet Grinding? (Ball Mills)

Wet grinding involves mixing the material with water or another liquid to form a slurry before it enters the ball mill.

This process is often more efficient, consumes less energy per ton of material, and prevents issues like dust explosions. It is the preferred method for producing extremely fine particles, as the liquid helps disperse the material and prevent agglomeration.

Why Choose Dry Grinding? (Ball Mills & Hammermills)

Dry grinding is a simpler process that does not require a subsequent drying stage, which can save time and energy.

This is the only method possible in a hammermill. It is also a viable option for ball mills when the final product must be completely free of moisture or when adding a liquid would cause an unwanted chemical reaction.

Understanding the Trade-offs and Limitations

No single solution is perfect for every scenario. Understanding the downsides of each approach is critical for making an informed decision.

The Cost of Versatility: Ball Mills

While powerful, ball mills have higher capital and operational costs. Dry grinding in a ball mill, in particular, can be less energy-efficient than wet grinding.

The management and replacement of the grinding media also add another layer of operational complexity and cost.

The Limits of Simplicity: Hammermills

Hammermills are simpler but far less versatile. They are completely unsuitable for hard or highly abrasive materials, which would cause extreme wear on the hammers.

Additionally, the high-speed impact generates significant heat, making hammermills a poor choice for heat-sensitive materials that could melt or degrade.

Selecting the Right Mill for Your Application

Your choice should be guided by a clear understanding of your material and your final goal.

- If your primary focus is producing a fine slurry or achieving the smallest possible particle size: A ball mill configured for wet grinding is the superior choice for its efficiency and dispersion capabilities.

- If your primary focus is quickly breaking down brittle, non-abrasive materials without liquids: A hammermill offers a simpler, more cost-effective, and direct solution.

- If your primary focus is grinding hard, abrasive materials where moisture is a concern: A ball mill set up for dry grinding provides the necessary force and process control.

Understanding these core principles allows you to select a milling process that aligns perfectly with your material and production goals.

Summary Table:

| Mill Type | Primary Mechanism | Suitable for Wet Grinding? | Suitable for Dry Grinding? | Ideal Material Types |

|---|---|---|---|---|

| Ball Mill | Impact & Attrition | Yes | Yes | Hard, abrasive materials |

| Hammermill | High-Speed Impact | No | Yes (only) | Brittle, fibrous, non-abrasive materials |

Need help selecting the right mill for your specific application? Our experts at KINTEK specialize in lab equipment and consumables, serving all your laboratory grinding needs. We can help you choose the perfect solution for your material properties and production goals. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- Why is a laboratory ball mill used in Co-Ni catalyst research? Optimize CO2 Conversion with Precise Milling

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials