For an accurate structure-to-soil potential reading, the copper/copper sulfate reference electrode must be placed in a vertical position, ensuring its porous tip makes direct and firm contact with the soil. This placement should typically be on the ground surface directly over the buried metallic structure you are measuring.

The goal of proper electrode placement is to create a stable and reliable electrical circuit between the electrode and the structure via the soil. The accuracy of your measurement is a direct reflection of the quality of this connection.

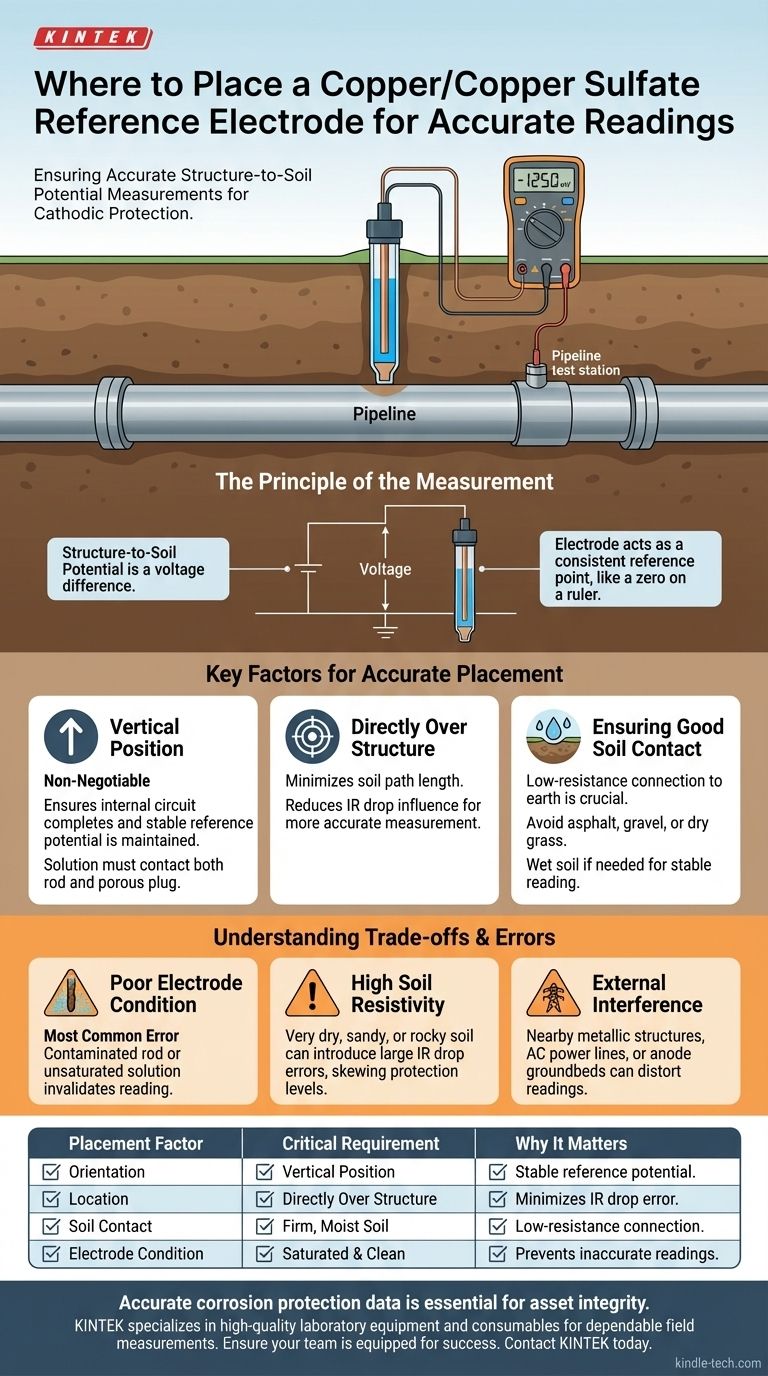

The Principle of the Measurement

A structure-to-soil potential reading is not an absolute value; it is a voltage difference. Understanding this is key to appreciating why placement is so critical.

What is a Structure-to-Soil Potential?

This measurement is the difference in electrical potential between a buried metallic structure (like a pipeline) and the soil immediately surrounding it. It is the primary indicator used to determine the effectiveness of a cathodic protection system designed to prevent corrosion.

The Role of the Reference Electrode

The copper/copper sulfate electrode provides a stable, known electrochemical potential. It acts as a consistent reference point, similar to the "zero" mark on a ruler. By connecting a voltmeter between the structure and this stable reference, you can accurately measure the structure's potential relative to the soil.

Why a Vertical Position is Non-Negotiable

The electrode must be held vertically to function correctly. Inside the electrode, a copper rod is submerged in a saturated copper sulfate solution. This solution must be in contact with both the rod and the porous plug at the bottom. Placing it vertically ensures this internal circuit is complete and the stable reference potential is maintained.

Key Factors for Accurate Placement

Beyond the vertical orientation, two other factors are critical for a trustworthy reading.

Placement Directly Over the Structure

For most standard surveys, the electrode should be placed on the ground directly above the asset being tested. This positioning minimizes the length of the soil path in the measurement circuit. A shorter path reduces the influence of soil resistance (known as IR drop), which can otherwise introduce significant error into your reading.

Ensuring Good Soil Contact

The electrode's porous plug must have a low-resistance electrical connection to the earth. This means placing it on soil, not on dry grass, asphalt, or gravel. If the ground is excessively dry or frozen, you may need to wet the location with a small amount of water to ensure a good connection and a stable reading.

Understanding the Trade-offs and Errors

In an ideal world, the measurement would be perfect. In the field, you must be aware of common sources of inaccuracy.

Poor Electrode Condition

The most common source of error is a poorly maintained electrode. If the copper sulfate solution is not saturated (i.e., you can't see visible copper sulfate crystals) or the copper rod is contaminated, the electrode will not provide a stable reference potential. This invalidates any reading you take.

High Soil Resistivity

In very dry, sandy, or rocky soils, the electrical resistance of the soil itself can be high. This high resistance can make it difficult to get a stable reading and can introduce a large IR drop error, making the structure's potential appear more protected (more negative) than it actually is.

External Interference

Placing the electrode near other buried metallic structures, AC power lines, or the anode groundbeds of other cathodic protection systems can cause interference. These external electrical fields can influence your voltmeter's reading, leading to inaccurate conclusions about your structure's level of protection.

Making the Right Choice for Your Goal

Your specific goal dictates the precise placement strategy.

- If your primary focus is a routine pipe-to-soil survey: Place the electrode vertically on the soil surface directly above the pipeline at your designated test intervals.

- If you encounter dry, paved, or frozen ground: Use a pre-soaked sponge or create a small, wet spot with water to bridge the gap and ensure a good electrical connection.

- If your readings are unstable or suspect: First, check that your electrode is properly maintained and saturated. Second, slightly adjust the placement to ensure it's not on a hidden rock or air pocket.

By rigorously controlling the placement of your reference electrode, you ensure your data is a reliable indicator of your asset's integrity.

Summary Table:

| Placement Factor | Critical Requirement | Why It Matters |

|---|---|---|

| Orientation | Vertical Position | Ensures internal solution contacts the rod and porous plug for a stable reference potential. |

| Location | Directly Over the Structure | Minimizes soil path length (IR drop) to reduce measurement error. |

| Soil Contact | Firm Contact with Moist Soil | Creates a low-resistance electrical connection to the earth for a stable reading. |

| Electrode Condition | Saturated Solution & Clean Rod | A poorly maintained electrode is the most common source of inaccurate readings. |

Accurate corrosion protection data is essential for asset integrity.

Your cathodic protection surveys are only as reliable as your reference electrode placement and equipment. KINTEK specializes in high-quality laboratory equipment and consumables, providing the precise tools and expert support needed for dependable field measurements.

Ensure your team is equipped for success. Contact KINTEK today to discuss your laboratory and field equipment needs and let our experts help you achieve accurate, trustworthy results.

Visual Guide

Related Products

- Copper Sulfate Reference Electrode for Laboratory Use

- Electrolytic Electrochemical Cell for Coating Evaluation

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

- Flat Corrosion Electrolytic Electrochemical Cell

- Metal Disc Electrode Electrochemical Electrode

People Also Ask

- What are the main maintenance and care instructions for gold and platinum sheets? Ensure Longevity and Pristine Performance

- What is the ideal storage environment for the PTFE electrode stand? Protect Your Lab's Precision

- Why must platinum paste electrodes be fired at 1100°C? Unlock High Conductivity and Mechanical Stability

- What are the advantages of using high-purity graphite electrodes as cathodes? Optimize Your Micro-Arc Oxidation Setup

- What roles do platinum electrodes and Ag/AgCl electrodes play in coating analysis? Ensuring Precision in Testing

- What advantages do tungsten electrodes provide compared to steel in CGDE? Superior Stability & Chemical Resistance

- What is the reference electrode wire for Ag AgCl? The Core of Stable Electrochemical Measurements

- Why is a silver chloride electrode used as a reference electrode? For Stable, Safe, and Reliable Measurements