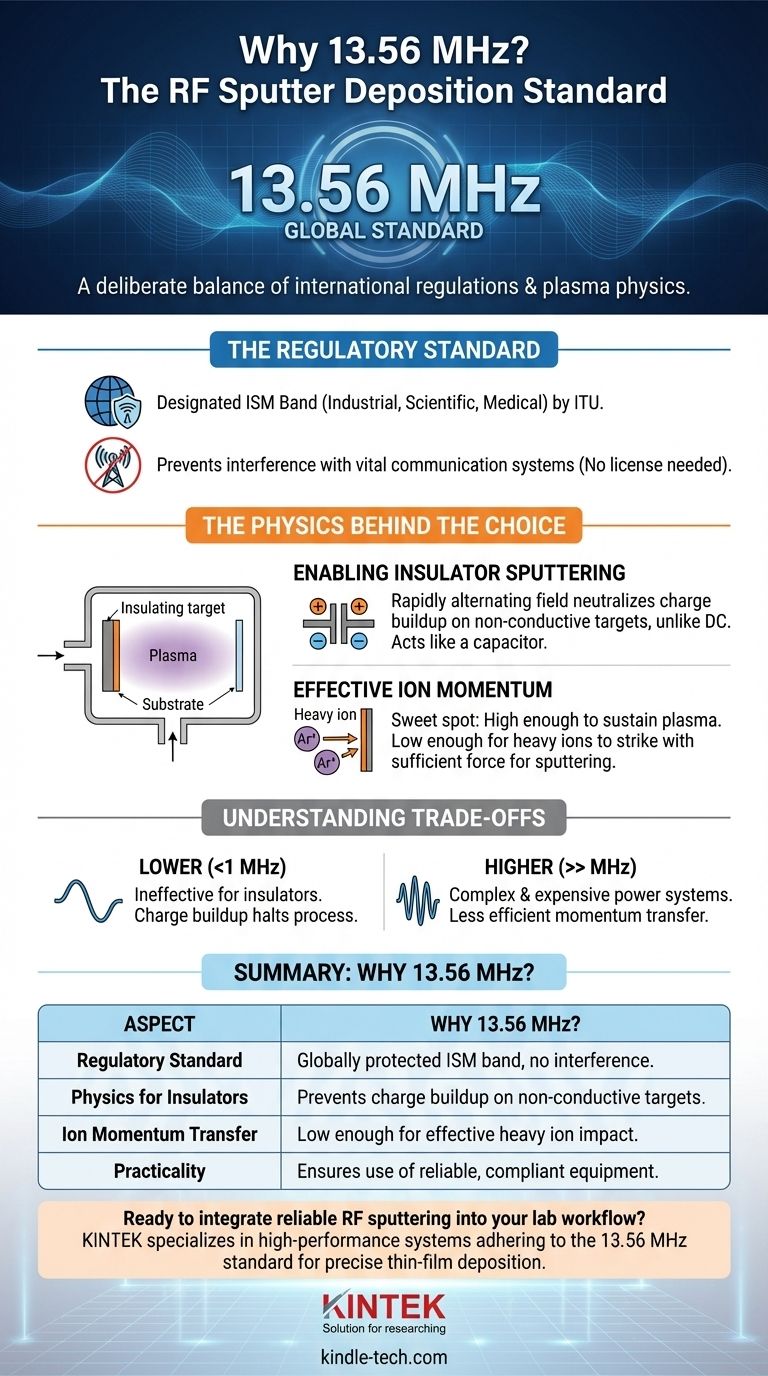

For RF sputter deposition, the universally accepted and most commonly used frequency is 13.56 MHz. This specific frequency is chosen not only for its physical effectiveness in the sputtering process but also because it is a globally regulated standard, preventing interference with critical communication systems.

The selection of 13.56 MHz is a deliberate engineering compromise. It balances international radio frequency regulations with the physical requirements needed to sustain a plasma and efficiently sputter non-conductive materials.

Why 13.56 MHz is the Global Standard

The choice of this exact frequency is driven primarily by regulation, which conveniently aligns with the needs of the physics involved.

The Role of ISM Bands

The International Telecommunication Union (ITU) has designated specific frequency bands for Industrial, Scientific, and Medical (ISM) purposes.

The 13.56 MHz frequency sits within one of these ISM bands. This allows equipment like RF sputtering systems to operate without requiring a special license or causing interference.

Preventing Telecommunication Interference

By operating within this protected band, RF generators used in sputtering systems are guaranteed not to disrupt vital radio, broadcast, or telecommunication services. This standardization is critical for the reliable deployment of such equipment in any lab or industrial setting worldwide.

The Physics Behind the Frequency Choice

Beyond regulation, the 13.56 MHz frequency is highly effective for the sputtering process itself, especially for insulating materials.

Enabling Sputtering of Insulators

In DC sputtering, a positive charge builds up on an insulating target, repelling the positive ions and quickly stopping the sputtering process. RF sputtering solves this.

At frequencies of 1 MHz or higher, the rapidly alternating electric field allows the insulating target to be alternately bombarded by ions and then electrons. This neutralizes the charge buildup on the target surface each cycle, enabling continuous sputtering.

Essentially, the insulating target acts like a capacitor in the RF circuit, allowing an effective current to flow and sustain the plasma.

Ensuring Effective Momentum Transfer

The 13.56 MHz frequency is also in a sweet spot for the plasma physics. It is high enough to efficiently sustain the plasma and prevent charge accumulation.

Simultaneously, it is low enough that heavy ions, such as Argon (Ar+), can still gain sufficient momentum from the electric field to strike the target with force. If the frequency were much higher, the heavy ions wouldn't be able to respond to the rapidly changing field and would have less impact energy.

Understanding the Trade-offs

While 13.56 MHz is the standard, understanding the boundaries helps clarify why it was chosen.

The Problem with Lower Frequencies

Operating below approximately 1 MHz would be ineffective for sputtering insulating materials. The alternating cycle would be too slow to prevent the target from electrically charging, which would halt the process just as it does in DC sputtering.

The Problem with Higher Frequencies

Using significantly higher frequencies (e.g., in the hundreds of MHz) would create new challenges. It would require more complex and expensive RF power delivery systems (impedance matching becomes more difficult) and could result in less efficient momentum transfer from the plasma ions to the target.

Making the Right Choice for Your Application

For nearly all users, adhering to the standard is the correct and only practical path forward.

- If your primary focus is standard thin-film deposition: Using the industry-standard 13.56 MHz is the only practical choice, as it ensures you are using compliant, reliable, and widely available equipment.

- If your primary focus is sputtering any insulating or dielectric material: RF sputtering at 13.56 MHz is essential, as DC methods will not work due to target charging.

- If your primary focus is experimental research: Deviating from 13.56 MHz would require custom-built power supplies and matching networks, along with careful shielding to avoid significant regulatory issues with radio interference.

Ultimately, the 13.56 MHz standard provides a robust and globally accepted foundation for virtually all modern RF sputtering applications.

Summary Table:

| Aspect | Why 13.56 MHz? |

|---|---|

| Regulatory Standard | Part of the globally protected ISM band, preventing interference with communications. |

| Physics for Insulators | High enough to prevent charge buildup on non-conductive targets. |

| Ion Momentum Transfer | Low enough for heavy ions (like Ar+) to respond and sputter effectively. |

| Practicality | Ensures use of reliable, widely available, and compliant equipment. |

Ready to integrate reliable RF sputtering into your lab workflow?

KINTEK specializes in high-performance lab equipment, including RF sputtering systems that adhere to the 13.56 MHz global standard. Our solutions ensure precise, consistent thin-film deposition for your research and production needs, helping you avoid regulatory issues and achieve superior results with insulating materials.

Contact us today to discuss how our sputtering technology can advance your projects.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What increases tensile strength? Key Methods to Enhance Material Strength and Performance

- Why is a precision drying oven required for TiO2 wet gel? Ensure Structural Integrity & Porosity

- What is pyrolysis oil made of? A Deep Dive into Its Complex Chemical Composition

- How does temperature affect biomass pyrolysis? Master the Key to Biochar, Bio-Oil, and Syngas Yields

- What is spark plasma sintering also called as? Unlocking FAST for Advanced Materials

- What are the side effects of CBD Distillate? Understanding Mild Effects and Critical Risks

- What are melting point standards? Ensure Accurate Temperature Measurements in Your Lab

- What is sintering in powder metallurgy? The Key to Strong, Dense Metal Parts