The definitive answer is that neither a roller mill nor a hammer mill is universally "better." The optimal choice depends entirely on your specific goals for particle size, the type of material you are processing, and your operational priorities like energy efficiency and maintenance. A roller mill excels at creating a uniform, coarse-to-medium grind for single grains, while a hammer mill is a versatile tool for fine grinding and handling a wide variety of ingredients.

Your decision is not about choosing a superior machine, but about matching the right grinding technology to your end product. The core difference lies in how they break down material: the controlled crushing of a roller mill versus the high-impact shattering of a hammer mill.

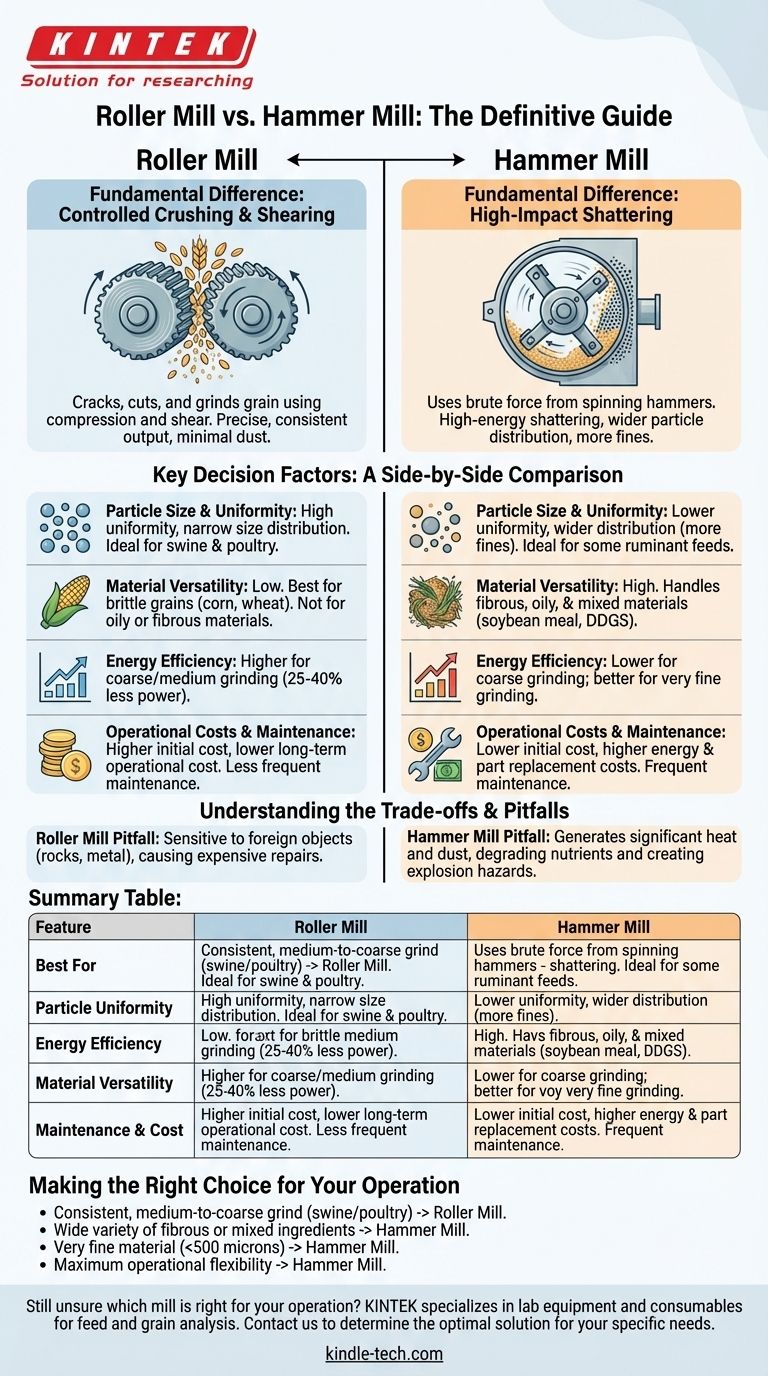

The Fundamental Difference: How They Work

To choose correctly, you must first understand the distinct mechanical principles behind each mill. Their method of particle reduction dictates their strengths and weaknesses.

The Roller Mill: Controlled Crushing and Shearing

A roller mill uses two or more cylindrical rolls (corrugated "teeth") that rotate at different speeds. As grain passes between them, it is subjected to a combination of compression and shear forces.

This action cracks, cuts, and grinds the material in a highly predictable way. The gap between the rolls and the design of the corrugation are the primary controls for the final particle size.

Think of it as a precise cracking and tearing action, designed to produce a consistent output with minimal fine dust.

The Hammer Mill: High-Impact Shattering

A hammer mill operates on the principle of brute force. Inside a grinding chamber, multiple hammers are mounted on a rotor that spins at very high speeds.

Material is fed into the chamber and repeatedly struck by these hammers until the particles are small enough to pass through a perforated screen at the bottom. The size of the holes in the screen determines the maximum particle size.

This is a high-energy, shattering process that results in a less uniform particle size distribution, containing both fine and coarse particles.

Key Decision Factors: A Side-by-Side Comparison

Your choice will hinge on how you prioritize the following operational factors.

Particle Size and Uniformity

This is the most critical differentiator. A roller mill produces a narrow and uniform particle size distribution. This is ideal for monogastric animals like swine and poultry, where consistency improves digestibility.

A hammer mill produces a wider, less uniform particle size distribution, with a greater percentage of very fine and very coarse particles. This can be desirable for some ruminant feeds but can cause issues with dust and feed flow.

Material Versatility

The hammer mill is the clear winner in versatility. It can effectively grind a vast range of materials, including fibrous or lower-density ingredients like soybean meal, distillers dried grains (DDGS), and mixed feed rations.

Roller mills are specialists. They perform best on brittle, free-flowing grains like corn, wheat, and sorghum. They are not effective for oily or fibrous materials, as these can clog the rollers.

Energy Efficiency

For coarse and medium grinding (above 600-700 microns), a roller mill is significantly more energy-efficient, potentially using 25-40% less power than a hammer mill for the same task. This is because crushing requires less energy than high-velocity impact.

For fine or very fine grinding, the energy efficiency gap narrows, and the hammer mill becomes the more practical tool.

Operational Costs and Maintenance

Hammer mills generally have a lower initial purchase price. However, their operational costs are higher due to greater energy consumption and the routine replacement of wearable parts like hammers and screens.

Roller mills have a higher initial capital cost. Their long-term operational costs are lower due to better energy efficiency and less frequent maintenance, which typically involves re-corrugating the rolls after extensive use.

Understanding the Trade-offs and Pitfalls

Objectivity requires acknowledging the downsides of each technology.

The Roller Mill's Blind Spot: Foreign Material

Roller mills are sensitive to foreign objects like rocks or metal. A small, hard object can severely damage the corrugation on the rolls, leading to expensive repairs and downtime. Powerful magnets are an essential prerequisite.

The Hammer Mill's Downside: Heat and Dust

The high-impact action of a hammer mill generates significant heat and dust. Heat can degrade heat-sensitive nutrients and vitamins in the feed. Excessive dust represents lost product and a potential explosion hazard if not managed properly.

The "Uniformity" Trap

While the uniform particles from a roller mill are generally positive, achieving the perfect grind is key. Too coarse, and digestibility suffers. Too fine, and you risk digestive issues like stomach ulcers in swine. The target particle size must be tailored to the specific animal species and their stage of life.

Making the Right Choice for Your Operation

Use your primary goal to guide your decision.

- If your primary focus is a consistent, medium-to-coarse grind for corn-based swine or poultry feed: A roller mill is your most energy-efficient and effective choice.

- If your primary focus is grinding a wide variety of fibrous or mixed ingredients: A hammer mill provides the necessary versatility that a roller mill lacks.

- If your primary focus is producing very fine material (under 500 microns) for aquaculture or specialty feeds: A hammer mill is the required tool for the job.

- If your primary focus is maximizing operational flexibility for a commercial feed mill: A hammer mill is often the default choice due to its ability to handle nearly any ingredient thrown at it.

By aligning the machine's inherent function with your specific production goals, you can select the right tool for an optimal and profitable operation.

Summary Table:

| Feature | Roller Mill | Hammer Mill |

|---|---|---|

| Best For | Uniform, coarse-to-medium grind (e.g., swine/poultry feed) | Versatile fine grinding & mixed ingredients |

| Particle Uniformity | High - narrow size distribution | Lower - wider size distribution (more fines) |

| Energy Efficiency | Higher for coarse/medium grinding | Lower for coarse grinding; better for very fine grinding |

| Material Versatility | Low (best for brittle grains like corn, wheat) | High (handles fibrous, oily, mixed materials) |

| Maintenance & Cost | Higher initial cost, lower long-term operational cost | Lower initial cost, higher energy & part replacement costs |

Still unsure which mill is right for your operation?

At KINTEK, we specialize in lab equipment and consumables for feed and grain analysis. Our experts can help you determine the optimal grinding solution for your specific materials and production goals.

Contact us today via our contact form to discuss your needs and ensure you invest in the right technology for maximum efficiency and profitability.

Visual Guide

Related Products

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What type of food samples grind by hammer mill? Ideal for Dry, Brittle, Low-Fat Materials

- Why is a laboratory ball mill required for ultra-fine fly ash? Unlock Nano-Scale Adsorption Power

- What dual processes can jet milling accomplish? Master Micronization and Classification in One Step

- Why use grinding equipment for NaOH and KOH in carbon fiber recovery? Achieve Efficient Eutectic Melting

- What grinding media is used in a ball mill? Select the Right Media for Maximum Efficiency and Purity

- What is the function of a 3D motion mixer with WC balls for high-entropy alloys? Ensure Perfect Powder Homogeneity

- What is the efficiency of ball milling? Unlocking Its Power Despite Energy Inefficiency

- What are the design advantages of the grinding chambers in jet mills? Achieve Ultra-Pure Size Reduction Without Wear