The short answer is that there is no single type of mill used for grinding; the choice depends entirely on the material and the desired outcome. The most common types for general-purpose applications are ball mills and hammermills, but specialized tasks require different equipment like jet mills or colloid mills.

The critical insight is that selecting a grinding mill is not about finding the "best" one, but about matching the mill's mechanical principle to the specific properties of your material—such as its hardness, viscosity, or heat sensitivity.

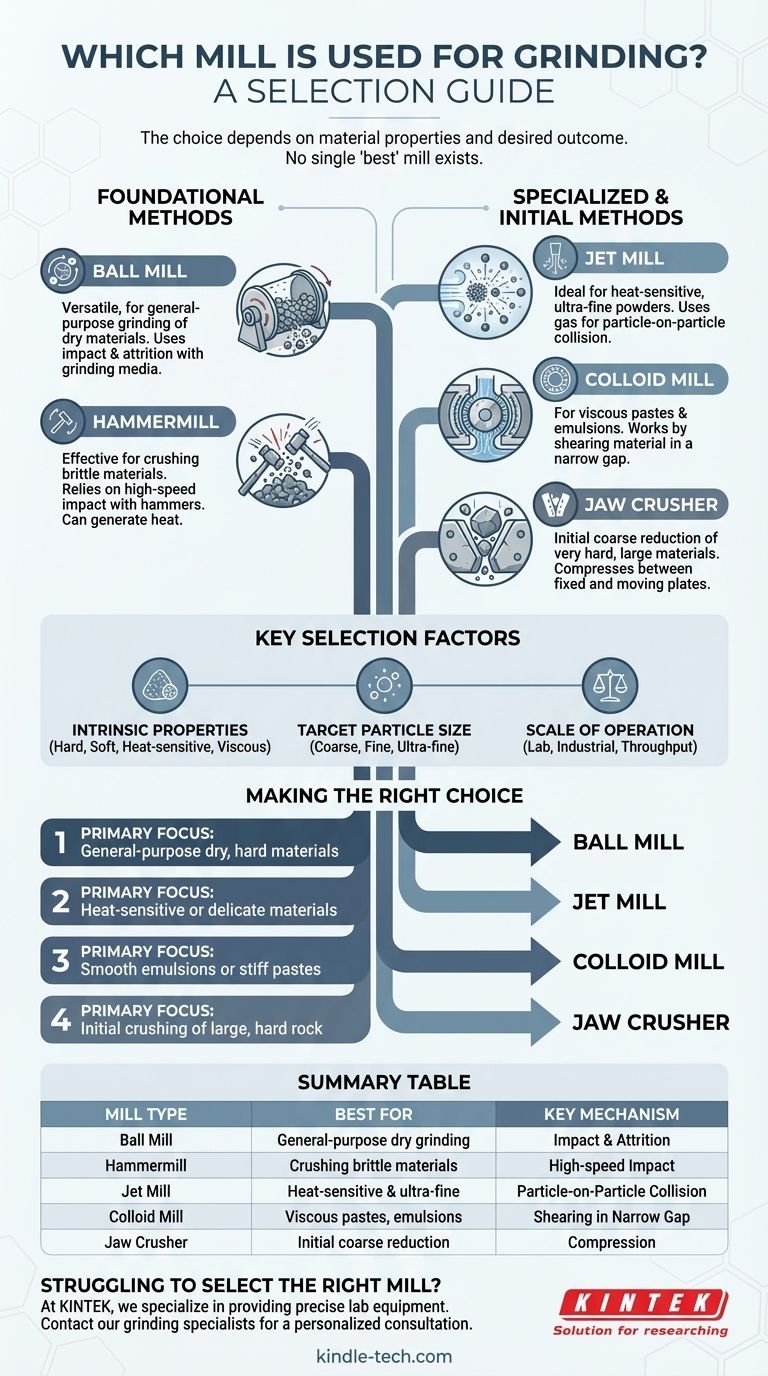

Foundational Grinding Methods

Different mills use distinct physical forces to achieve particle size reduction. Understanding these core methods is the first step in making an informed choice.

Ball Mills for Versatile Grinding

A ball mill is a foundational piece of equipment in many labs and industrial settings. It uses a rotating cylinder filled with grinding media (like ceramic or steel balls) to break down material through impact and attrition.

They are highly versatile and can handle a wide range of materials, making them a common choice for many applications.

Hammermills for Brittle Materials

Hammermills use high-speed rotating hammers to shatter and pulverize material. This method relies on brute-force impact.

This makes them effective for crushing brittle materials but less suitable for substances that are gummy or heat-sensitive, as the process can generate significant friction and heat.

Specialized Mills for Unique Materials

When dealing with materials that have specific sensitivities or physical properties, a specialized mill is required to achieve the desired result without damaging the sample.

Jet Mills for Heat-Sensitive Materials

A jet mill is the ideal solution for heat-sensitive powders. It uses high-velocity jets of compressed gas to propel particles, causing them to collide with one another and break apart.

Because this process generates very little heat and involves no moving grinding parts, it preserves the integrity of materials that would otherwise melt or degrade.

Colloid Mills for Viscous Pastes

For materials that are already in a paste or liquid form, a colloid mill is the appropriate choice. It works by shearing the material as it passes through a narrow gap between a static and a high-speed rotating element.

This is the standard method for processing stiff pastes, emulsions, and other high-viscosity materials that require a smooth, uniform texture.

Jaw Crushers for Initial Coarse Reduction

A jaw crusher is often used for the first stage of size reduction on very hard, large materials. It compresses material between a fixed and a moving plate (the "jaws").

This is not for fine grinding but is essential for breaking down large chunks into a manageable size for subsequent processing in a finer mill.

Understanding the Key Selection Factors

Choosing the right mill requires you to weigh a few critical trade-offs based on your material and your goals. Ignoring these factors is the most common source of poor grinding results.

The Material's Intrinsic Properties

The most important factor is the nature of your material. Is it hard and brittle? Soft and fibrous? Heat-sensitive? A viscous liquid?

Each of these properties points directly to a specific type of mill that is best suited for the task.

The Target Particle Size

You must consider your desired final particle size. A jaw crusher provides a coarse output, while a ball mill can achieve a finer grind.

A jet mill is capable of producing extremely fine particles (micron or sub-micron level) that are often impossible to achieve with mechanical mills.

The Scale of Operation

Finally, consider your throughput needs. Mills range from small desktop lab units that can process a few kilograms per hour to large industrial mills designed for continuous, high-volume production.

Making the Right Choice for Your Application

Use your primary goal to guide your selection.

- If your primary focus is general-purpose grinding of dry, hard materials: A ball mill offers the most versatility for a wide range of applications.

- If your primary focus is grinding heat-sensitive or delicate materials: A jet mill is the only choice that avoids mechanical heat generation.

- If your primary focus is creating a smooth emulsion or grinding a stiff paste: A colloid mill is specifically engineered for this purpose.

- If your primary focus is the initial crushing of large, hard rock-like material: A jaw crusher is the necessary first step before any fine grinding can occur.

Ultimately, a successful grinding operation begins with a clear understanding of your starting material and your final goal.

Summary Table:

| Mill Type | Best For | Key Mechanism |

|---|---|---|

| Ball Mill | General-purpose grinding of dry materials | Impact & attrition with grinding media |

| Hammermill | Crushing brittle, friable materials | High-speed impact with hammers |

| Jet Mill | Heat-sensitive materials & ultra-fine grinding | Particle-on-particle collision with gas |

| Colloid Mill | Viscous pastes, emulsions, & liquids | Shearing in a narrow gap |

| Jaw Crusher | Initial coarse reduction of hard, large materials | Compression between fixed and moving plates |

Struggling to select the right mill for your specific material and target particle size?

At KINTEK, we specialize in providing the precise lab equipment you need for efficient and effective grinding. Whether you are processing heat-sensitive powders, creating smooth emulsions, or require coarse crushing, our experts can help you choose the perfect solution from our range of ball mills, jet mills, and more.

Let us help you achieve superior results. Contact our grinding specialists today for a personalized consultation and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the advantage of using high-hardness Zirconia grinding balls for the milling of Na3SbS4-xSex electrolytes?

- What factors affect ball mill operation? Master the Variables for Optimal Grinding

- Why use zirconia grinding media of varying diameters for LATP? Optimize Efficiency and Purity in Solid-State Synthesis

- What is the purpose of a pulverizer? Unlock Material Potential with Fine Grinding

- Why Use a Ball Mill for Ethanol-Based Wet Mixing of Fe-Ni/Zr2P2WO12? Achieve Homogeneous Material Dispersion

- Why is high-precision mixing and grinding equipment necessary for fluorine doping in anti-perovskite materials?

- How does a laboratory ball mill prepare catalysts like CuAlO2? Enhancing Efficiency with Mechanical Alloying

- What is the function of a ball mill during LLZTO precursor mixing? Master Microscopic Homogeneity for Electrolytes