At its core, you need sieve analysis because it is a fundamental quality control method for determining the particle size distribution of a granular material. This analysis provides critical insight into the physical characteristics of materials like sand, powders, grains, and crushed rock, ensuring they meet the specific requirements for performance, safety, and consistency in their final application.

Understanding a material's particle size isn't just an academic exercise; it directly dictates how that material will behave. Sieve analysis offers a reliable, cost-effective, and universally understood method to measure and control this critical variable.

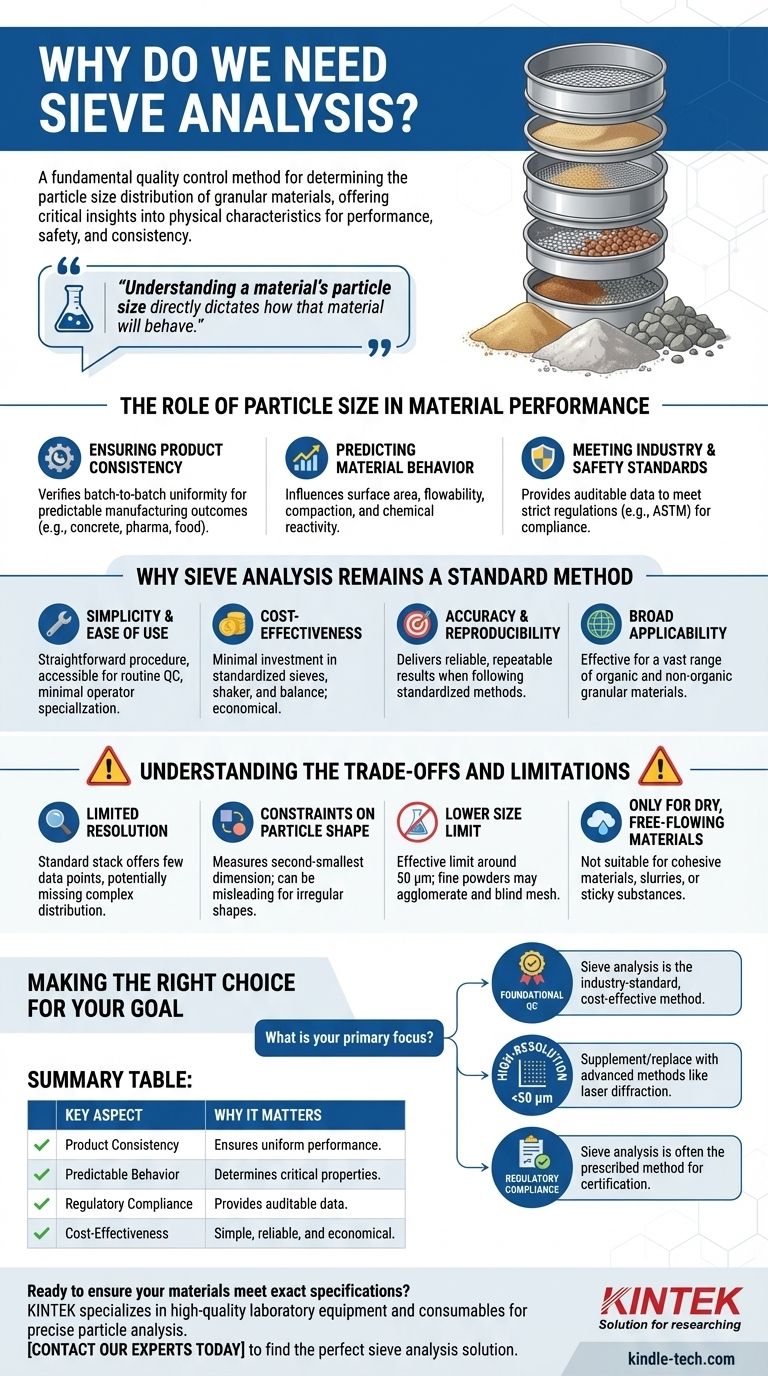

The Role of Particle Size in Material Performance

The distribution of particle sizes within a sample has a direct and measurable impact on its bulk properties. Controlling this distribution is essential for achieving predictable and desirable outcomes.

Ensuring Product Consistency

For manufacturers, consistency is paramount. Whether producing concrete, pharmaceuticals, or food products, a consistent particle size distribution ensures that each batch behaves the same way as the last. Sieve analysis is the primary tool for verifying this consistency from batch to batch.

Predicting Material Behavior

Particle size directly influences key physical properties. The surface area, flowability, compaction density, and even the chemical reactivity of a powder are all functions of its particle size. By measuring the distribution, engineers and scientists can predict how the material will perform.

Meeting Industry and Safety Standards

Many industries, particularly construction and pharmaceuticals, operate under strict standards (such as ASTM) that specify acceptable particle size ranges. Sieve analysis provides the auditable, traceable data required to prove that a material is compliant and fit for purpose.

Why Sieve Analysis Remains a Standard Method

Despite the availability of more advanced technologies, traditional sieve analysis has remained a cornerstone of particle analysis for centuries due to its compelling practical advantages.

Simplicity and Ease of Use

The procedure is straightforward and mechanical. It does not require highly specialized operators, making it accessible for routine quality control on a factory floor or in a field lab.

Cost-Effectiveness

The required equipment—a standardized set of sieves, a mechanical shaker, and a balance—represents a minimal investment. This makes it the most economical method for many applications.

Accuracy and Reproducibility

When performed according to a standardized method, sieve analysis delivers accurate and repeatable results. This reliability is why it is so often cited in industrial and material specifications.

Broad Applicability

The method is effective for a vast range of organic and non-organic granular materials. It is used for everything from sand, clay, and crushed rock to coal, manufactured powders, seeds, and grains.

Understanding the Trade-offs and Limitations

While powerful, sieve analysis is not the solution for every scenario. Acknowledging its limitations is key to using it effectively.

Limited Resolution

A standard sieve stack uses a maximum of about eight sieves. This means your final particle size distribution curve is based on only a few data points, which may not capture the full complexity of the material.

Constraints on Particle Shape

Sieve analysis measures the second-smallest dimension of a particle, as elongated or flat particles can orient themselves to pass through a mesh opening. This can provide a misleading picture if the particle shape is highly irregular.

Lower Size Limit

The effectiveness of mechanical sieving diminishes for very fine powders. The practical lower limit for this method is typically around 50 micrometers (µm); below this, particles can agglomerate and blind the mesh.

Only for Dry, Free-Flowing Materials

The standard method is designed for dry materials that can pass freely through the sieves. It is not suitable for cohesive materials, slurries, or substances that stick together when agitated.

Making the Right Choice for Your Goal

Use this guidance to determine if sieve analysis fits your specific need.

- If your primary focus is foundational quality control for granular materials: Sieve analysis is the industry-standard, most cost-effective method for verifying material specifications.

- If your primary focus is high-resolution analysis of very fine powders (<50 µm): You will need to supplement or replace sieve analysis with more advanced methods like laser diffraction or dynamic image analysis.

- If your primary focus is ensuring compliance with established industrial standards: Sieve analysis is often the prescribed method, providing the necessary documentation and traceability for certification.

By understanding both its purpose and its practical limits, you can leverage sieve analysis to make confident and informed decisions about your material quality and process control.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Product Consistency | Ensures uniform performance from batch to batch in manufacturing. |

| Predictable Behavior | Determines critical properties like flowability, compaction, and reactivity. |

| Regulatory Compliance | Provides auditable data to meet strict industry standards (e.g., ASTM). |

| Cost-Effectiveness | Offers a simple, reliable, and economical method for routine quality control. |

Ready to ensure your materials meet exact specifications?

KINTEK specializes in high-quality laboratory equipment and consumables for precise particle analysis. Our range of reliable sieves and shakers helps laboratories maintain the highest standards of quality control for materials like sand, powders, and aggregates.

Contact our experts today to find the perfect sieve analysis solution for your laboratory's needs and achieve consistent, reliable results.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the function of sieving equipment in CuAlMn alloys? Master Pore Size Precision

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution