In the laboratory, sample preparation is not a preliminary task—it is often the most critical step. Grinding is a cornerstone of this process, essential for transforming a bulk, often inconsistent sample into a form suitable for analysis. It is important because it massively increases the surface area available for reactions, ensures the sample is uniform (homogeneous), and breaks down complex structures to release the components of interest, directly enabling faster, more efficient, and more accurate scientific measurements.

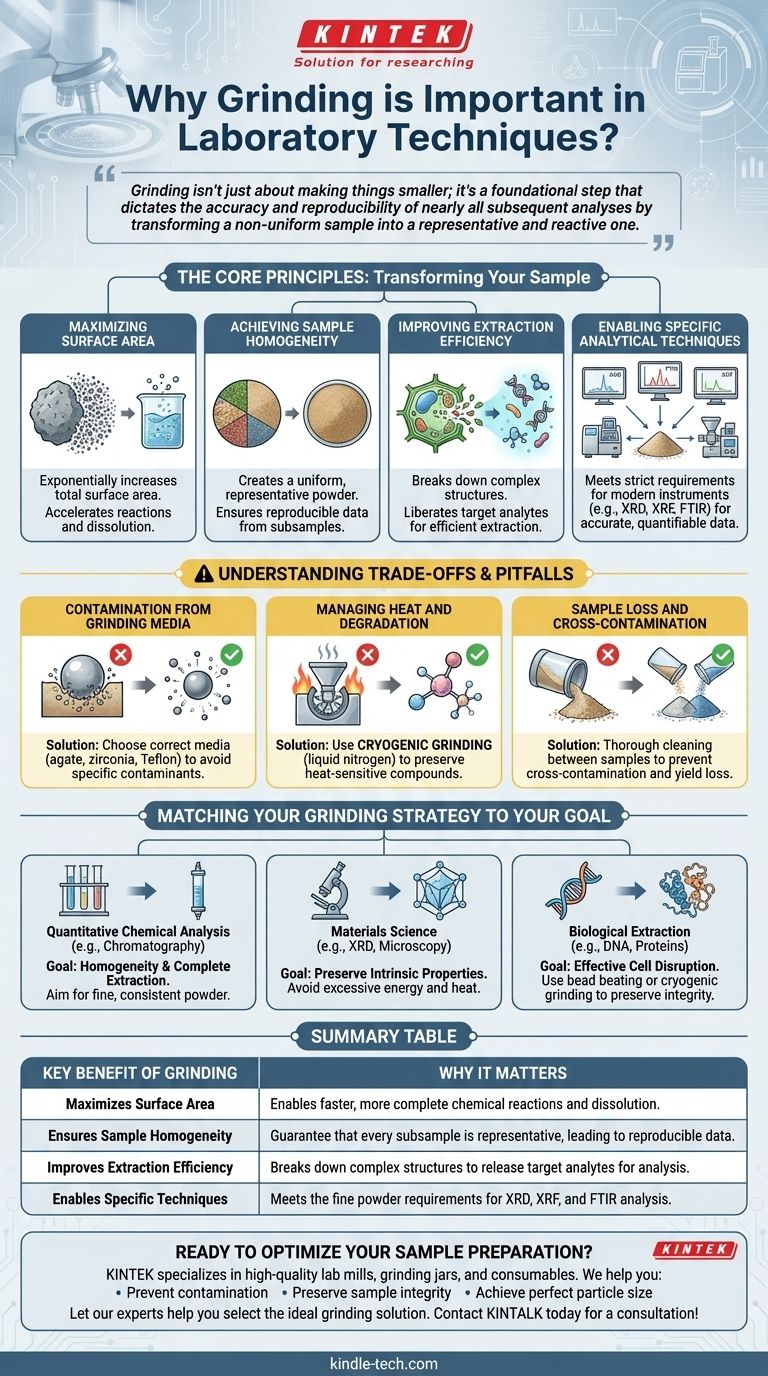

Grinding isn't just about making things smaller; it's a foundational step that dictates the accuracy and reproducibility of nearly all subsequent analyses by transforming a non-uniform sample into a representative and reactive one.

The Core Principles: Why Grinding Transforms Your Sample

To understand the importance of grinding, we must look at how it fundamentally alters the physical and chemical accessibility of a sample. Each principle addresses a common barrier to obtaining accurate data.

Maximizing Surface Area

Most chemical reactions, including dissolution and extraction, occur on the surface of a substance. Grinding shatters a large particle into millions of smaller ones, exponentially increasing the total surface area.

Think of dissolving a sugar cube versus an equal amount of granulated sugar in water. The granulated sugar dissolves almost instantly because the water can access a much larger surface area simultaneously.

Achieving Sample Homogeneity

A raw sample, whether it's a piece of rock, a plant leaf, or a synthesized polymer, is rarely uniform. One section may have a higher concentration of the analyte than another.

Grinding and subsequent mixing create a homogeneous powder. This ensures that any small subsample taken for analysis is statistically identical to any other subsample, making your results representative of the whole and, most importantly, reproducible.

Improving Extraction Efficiency

In biological, environmental, and pharmaceutical analyses, the target molecule is often locked within a complex matrix, such as a cell wall or a polymer binder.

Grinding physically breaks down these structures. This process, known as cell lysis in biology, liberates the target analytes (like DNA, proteins, or active ingredients), allowing solvents to access and extract them efficiently. Without this step, extractions would be incomplete, leading to falsely low measurements.

Enabling Specific Analytical Techniques

Many modern analytical instruments have strict requirements for sample form.

Techniques like X-Ray Diffraction (XRD), Fourier-Transform Infrared Spectroscopy (FTIR), and X-Ray Fluorescence (XRF) require finely powdered, homogeneous samples to produce clear, accurate, and quantifiable data. Incorrect particle size can cause signal distortion, peak broadening, or quantification errors.

Understanding the Trade-offs and Pitfalls

While grinding is essential, performing it incorrectly can introduce significant errors into your analysis. An expert approach involves understanding and mitigating these potential issues.

Contamination from Grinding Media

The material of the grinding equipment (e.g., a mortar and pestle or mill vials) can leech into the sample. Using a steel mill to grind a sample for trace metal analysis, for instance, would introduce significant iron and chromium contamination.

Choosing the right material—such as agate for general use, zirconia for hardness, or Teflon to avoid metallic contamination—is critical.

Managing Heat and Degradation

The friction from high-energy grinding generates heat. This can be enough to degrade thermally sensitive compounds, cause volatile components to evaporate, or even alter the crystalline structure of a material.

For heat-sensitive samples like biological tissues, plastics, or certain pharmaceuticals, cryogenic grinding is the solution. Freezing the sample with liquid nitrogen makes it brittle and keeps it cold, preserving its integrity during the process.

Sample Loss and Cross-Contamination

A portion of the sample can be lost as fine dust or by adhering to the surfaces of the grinding equipment. This is a major concern when working with precious or limited quantities of material.

Thorough cleaning of equipment between samples is non-negotiable to prevent cross-contamination, which can invalidate entire batches of results.

Matching Your Grinding Strategy to Your Goal

The right grinding approach is dictated entirely by your sample type and the objective of your analysis. Consider the following guidelines to make an informed choice.

- If your primary focus is quantitative chemical analysis (e.g., chromatography): Your goal is homogeneity and complete extraction. Aim for a fine, consistent powder that ensures any subsample is truly representative.

- If your primary focus is materials science (e.g., XRD, microscopy): Your goal is to reduce particle size without altering the material's intrinsic properties, like its crystal structure. Avoid excessive energy and heat generation.

- If your primary focus is biological extraction (e.g., DNA, proteins): Your goal is effective cell disruption without degrading the target molecules. Use methods like bead beating or cryogenic grinding to preserve sample integrity.

Ultimately, treating grinding as a precise scientific step, not an indiscriminate chore, is fundamental to generating reliable and meaningful data.

Summary Table:

| Key Benefit of Grinding | Why It Matters |

|---|---|

| Maximizes Surface Area | Enables faster, more complete chemical reactions and dissolution. |

| Ensures Sample Homogeneity | Guarantee that every subsample is representative, leading to reproducible data. |

| Improves Extraction Efficiency | Breaks down complex structures to release target analytes for analysis. |

| Enables Specific Techniques | Meets the fine powder requirements for XRD, XRF, and FTIR analysis. |

Ready to optimize your sample preparation?

The right grinding equipment is fundamental to achieving accurate and reproducible results. KINTEK specializes in high-quality lab mills, grinding jars, and consumables designed for a wide range of applications—from biological extraction to materials science.

We help you:

- Prevent contamination with a selection of grinding media (agate, zirconia, stainless steel).

- Preserve sample integrity with cryogenic grinding solutions for heat-sensitive materials.

- Achieve perfect particle size for your specific analytical technique.

Let our experts help you select the ideal grinding solution for your lab's needs. Contact KINTALK today for a consultation!

Visual Guide

Related Products

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory High Throughput Tissue Grinding Mill Grinder

People Also Ask

- What are the different types of laboratory mills? Choose the Right Grinder for Your Sample Material

- What is the particle size for XRD analysis? Optimize Your Results with the Right Preparation

- What is the function of a mortar and pestle in ZnS nanoparticle prep? Optimize Your Sample Refinement

- What is the function of an Agate Mortar and Pestle in sodium battery preparation? Ensure Contaminant-Free Mixing

- Why is an alumina mortar used for grinding dried Yttrium Oxide precursor materials? Ensure Maximum Purity and Quality