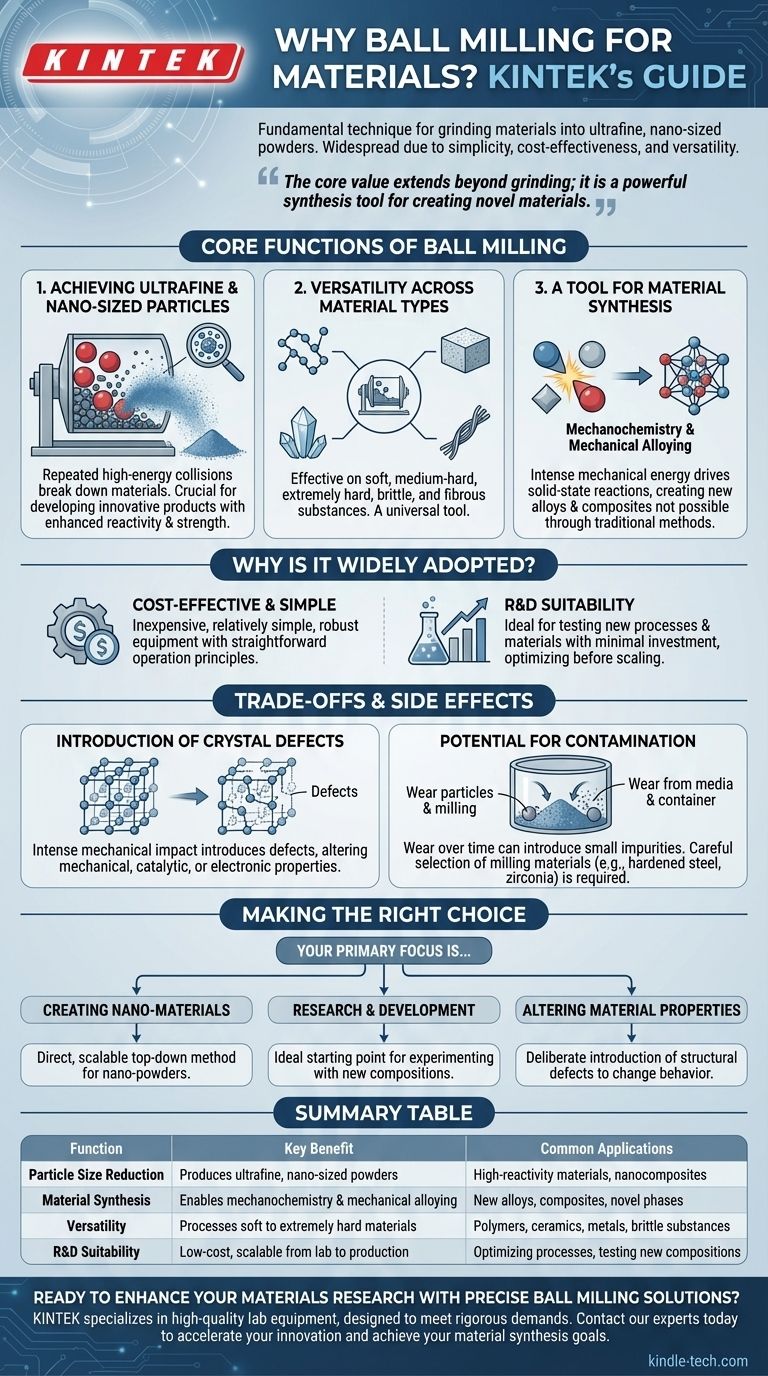

In materials science and engineering, ball milling is a fundamental technique used for grinding materials into extremely fine, often nano-sized, powders. Its widespread adoption stems from its remarkable simplicity, cost-effectiveness, and its ability to process a vast range of material types, from soft polymers to extremely hard ceramics.

The core value of ball milling extends beyond simple grinding; it is a powerful synthesis tool for creating novel materials with unique properties by aggressively reducing particle size and intentionally introducing structural changes.

The Core Functions of Ball Milling

The primary purpose of ball milling is to reduce the size of solid materials. However, the high-energy environment inside the mill enables several other critical functions.

Achieving Ultrafine and Nano-Sized Particles

The main objective of ball milling is often particle size reduction. The repeated, high-energy collisions between the grinding balls and the material can break down coarse powders into particles on the micrometer or even nanometer scale.

This ability to produce nano-sized materials is crucial for developing innovative products with enhanced properties, such as increased reactivity, improved strength, or unique optical characteristics.

Versatility Across Material Types

A key advantage of ball milling is its exceptional versatility. The mechanical grinding process is effective on a wide array of materials.

This includes soft, medium-hard, extremely hard, brittle, and fibrous substances, making it a nearly universal tool in materials processing laboratories.

A Tool for Material Synthesis

Beyond grinding, ball milling is a powerful method for synthesizing new materials. The intense mechanical energy can drive solid-state reactions, a process known as mechanochemistry or mechanical alloying.

This allows for the creation of alloys, composites, and other novel phases that might be difficult or impossible to produce through traditional melting or chemical routes.

Why is Ball Milling So Widely Adopted?

The technique's popularity is not just due to its functional capabilities but also its practical and economic advantages.

Cost-Effectiveness and Simplicity

Compared to many other advanced materials processing techniques, ball milling is inexpensive and relatively simple to perform. The equipment is robust and the operational principles are straightforward.

Suitability for Research and Development

Laboratory-scale milling equipment allows researchers to test new processes and materials with a minimal financial investment.

This makes it an ideal tool for development work, enabling numerous trials to optimize parameters like mill configuration, grinding time, and speed before scaling up for industrial production.

Understanding the Trade-offs and Side Effects

While powerful, the high-energy nature of ball milling has inherent consequences that must be managed.

The Introduction of Crystal Defects

The intense mechanical impact during milling does more than just break particles; it introduces a high density of crystal defects, such as dislocations and vacancies, into the material's structure.

While this can be considered a drawback if a perfect crystal is desired, these defects are often intentionally created to alter and enhance a material's mechanical, catalytic, or electronic properties.

Potential for Contamination

A significant practical concern is contamination from the grinding media (the balls) and the container itself. Over long milling times, wear can introduce small amounts of material from the mill into the powder.

This requires careful selection of milling materials (e.g., using hardened steel, tungsten carbide, or zirconia) to minimize unwanted impurities in the final product.

Making the Right Choice for Your Goal

The decision to use ball milling should be based on your specific material and desired outcome.

- If your primary focus is creating nano-materials: Ball milling is one of the most direct and scalable "top-down" methods for producing nano-sized powders from a bulk source.

- If your primary focus is research and development: Its low cost and operational simplicity make it an ideal starting point for experimenting with new material compositions and alloys.

- If your primary focus is altering material properties: The technique can be used deliberately not just for size reduction, but also to introduce structural defects that fundamentally change a material's behavior.

Ultimately, ball milling is an indispensable and versatile tool for manipulating and synthesizing materials at a fundamental level.

Summary Table:

| Function | Key Benefit | Common Applications |

|---|---|---|

| Particle Size Reduction | Produces ultrafine, nano-sized powders | Creating high-reactivity materials, nanocomposites |

| Material Synthesis | Enables mechanochemistry & mechanical alloying | Developing new alloys, composites, novel phases |

| Versatility | Processes soft to extremely hard materials | Polymers, ceramics, metals, brittle substances |

| R&D Suitability | Low-cost, scalable from lab to production | Optimizing processes, testing new material compositions |

Ready to enhance your materials research with precise ball milling solutions?

KINTEK specializes in high-quality lab equipment, including ball mills and grinding media, designed to meet the rigorous demands of materials science. Whether you are developing nano-powders, synthesizing new alloys, or optimizing your R&D processes, our robust and reliable equipment ensures consistent results while minimizing contamination.

Contact our experts today to discuss how KINTEK's ball milling solutions can accelerate your innovation and achieve your material synthesis goals.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Hybrid High Energy Vibratory Ball Mill for Lab Use

- Laboratory Four-Body Horizontal Jar Mill

People Also Ask

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity