In essence, co-pyrolysis is important because it solves the problems of standard pyrolysis. By processing two or more different materials together, such as biomass and plastic, it creates synergistic effects that improve the quality of the final bio-oil, increase the yield of valuable products, and allow for the efficient conversion of complex waste streams that are difficult to process alone.

Co-pyrolysis is not just about processing more waste; it's about using the chemical properties of one waste material to strategically upgrade another during the thermal process, turning low-value feedstocks into higher-value fuels and chemicals.

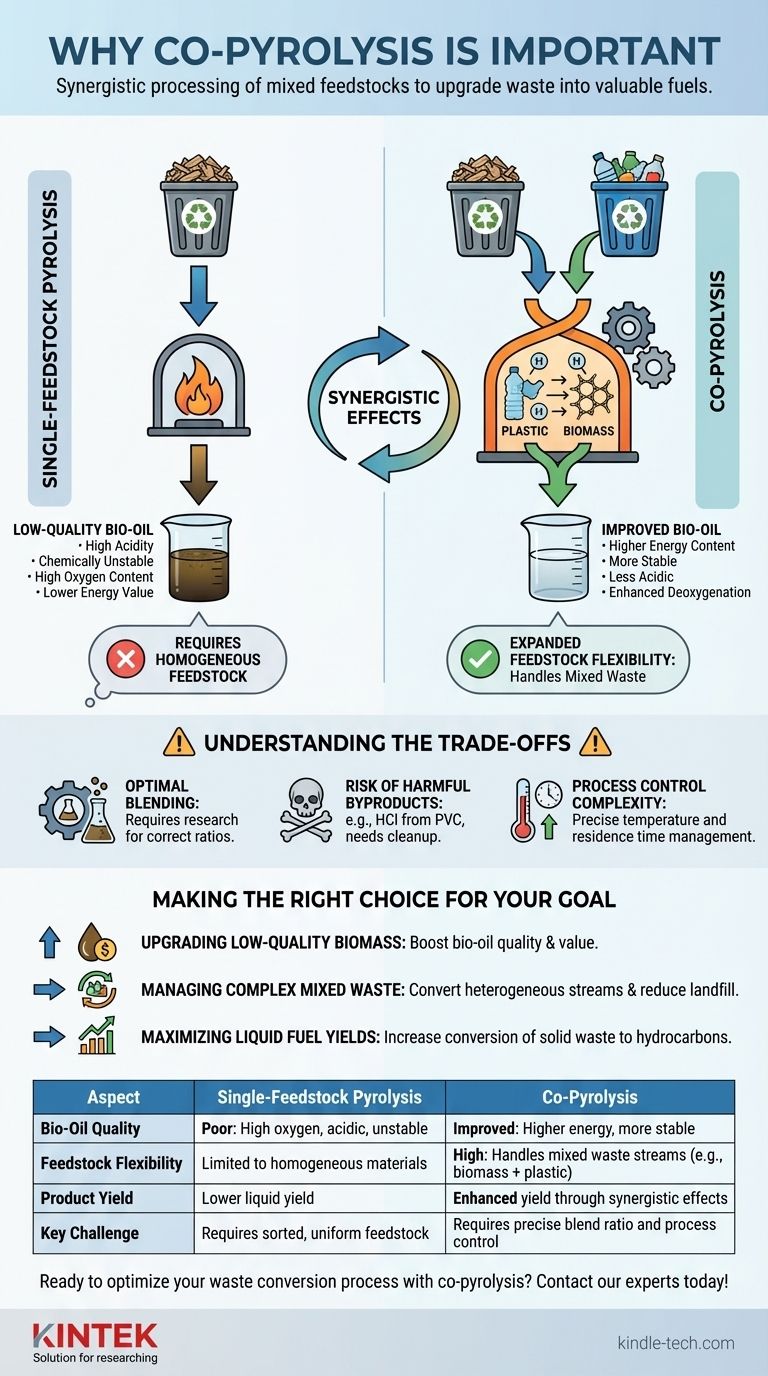

The Limitations of Single-Feedstock Pyrolysis

Pyrolysis is the thermal decomposition of organic material in the absence of oxygen. As a technology, it has been used for centuries to produce products like charcoal from wood. However, when applied to modern waste streams, processing a single type of feedstock presents significant challenges.

The Low-Quality Bio-Oil Problem

When pyrolyzing biomass (like wood or agricultural waste) alone, the resulting liquid fuel, known as bio-oil, is often of poor quality. It tends to be highly acidic, chemically unstable, and has a high oxygen content, which lowers its energy value.

The Feedstock Homogeneity Requirement

Standard pyrolysis works best with a uniform, predictable feedstock. This is a major drawback when dealing with real-world waste, such as municipal solid waste, which is a highly heterogeneous mixture of paper, plastic, food, and other materials.

How Co-Pyrolysis Creates Synergy

Co-pyrolysis overcomes these limitations by intentionally mixing different feedstocks to create beneficial chemical interactions within the reactor. The most common example is the co-pyrolysis of biomass and plastics.

Improving Fuel Quality

Plastics are rich in hydrogen and have a high heating value. When co-pyrolyzed with biomass, the hydrogen from the decomposing plastic acts as a "donor." This helps to remove oxygen from the biomass-derived compounds, a process called deoxygenation.

The result is a more stable, less acidic bio-oil with a higher energy content, making it a better candidate for upgrading into transportation fuels.

Enhancing Product Yields

The interactions between the different feedstocks can have a catalytic effect. Radicals and compounds produced from one material can influence the decomposition pathway of the other, often leading to a higher yield of desired liquid (bio-oil) or gaseous products than would be achieved by pyrolyzing each material separately and blending the results.

Expanding Feedstock Flexibility

Co-pyrolysis provides a robust technical solution for converting mixed waste streams. It removes the need for costly and often imperfect sorting processes, allowing facilities to directly process mixed plastics or blends of biomass and plastic, which more accurately reflects real-world waste composition.

Understanding the Trade-offs

While powerful, co-pyrolysis introduces its own set of complexities that require careful management. It is not a universally simple solution.

The Challenge of Optimal Blending

The synergistic effects are highly dependent on the blend ratio. An incorrect ratio of biomass to plastic can fail to produce the desired benefits or even lead to lower-quality products. Finding the optimal mix requires significant research and process control.

Risk of Harmful Byproducts

Co-processing certain materials can generate undesirable or toxic compounds. For example, pyrolyzing plastics containing chlorine (like PVC) can produce corrosive hydrochloric acid (HCl) or toxic dioxins, which require additional downstream cleanup systems.

Process Control Complexity

Different materials decompose at different temperatures and rates. Managing a co-pyrolysis reactor requires precise control over temperature and residence time to ensure both feedstocks are converted efficiently without compromising the process.

Making the Right Choice for Your Goal

Co-pyrolysis should be viewed as a strategic tool to be deployed when its specific benefits align with your primary objective.

- If your primary focus is upgrading low-quality biomass: Co-pyrolysis with a hydrogen-rich feedstock like plastic is one of the most effective methods to improve bio-oil quality and value.

- If your primary focus is managing complex mixed waste: Co-pyrolysis offers a powerful pathway to convert heterogeneous streams, like municipal solid waste, into valuable products while reducing landfill volume.

- If your primary focus is maximizing liquid fuel yields: The synergistic effects of co-pyrolysis can increase the conversion of solid waste into valuable liquid hydrocarbons, boosting overall process efficiency.

Ultimately, co-pyrolysis transforms the challenge of waste heterogeneity into an opportunity for chemical advantage.

Summary Table:

| Aspect | Single-Feedstock Pyrolysis | Co-Pyrolysis |

|---|---|---|

| Bio-Oil Quality | Poor: High oxygen, acidic, unstable | Improved: Higher energy, more stable |

| Feedstock Flexibility | Limited to homogeneous materials | High: Handles mixed waste streams (e.g., biomass + plastic) |

| Product Yield | Lower liquid yield | Enhanced yield through synergistic effects |

| Key Challenge | Requires sorted, uniform feedstock | Requires precise blend ratio and process control |

Ready to optimize your waste conversion process with co-pyrolysis? KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether you're exploring optimal blend ratios or scaling up mixed waste processing, our solutions help you achieve higher-quality biofuels and greater efficiency. Contact our experts today to discuss how we can support your laboratory's pyrolysis innovation goals.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the process of zirconium production? From Ore to High-Performance Metal & Ceramic

- Why is a high-temperature furnace with multi-probe testing used for ABO3 perovskite? Get Precise Conductivity Data

- At what temperature does wood pyrolysis begin? Control the Process for Biochar, Bio-Oil, or Syngas

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding

- What is the temperature of a rotary hearth furnace? Find the Right Heat for Your Process