The sieve test is important because it is a fundamental, reliable, and straightforward method for determining the particle size distribution of a granular material. This analysis is critical because the size of particles directly impacts a material's physical properties, performance, and quality across countless industries, from pharmaceuticals and food to mining and construction.

The true value of a sieve test isn't just in measuring particles; it's in providing the quantitative data needed to control a product's consistency, ensure it meets industry standards, and predict its behavior in a final application.

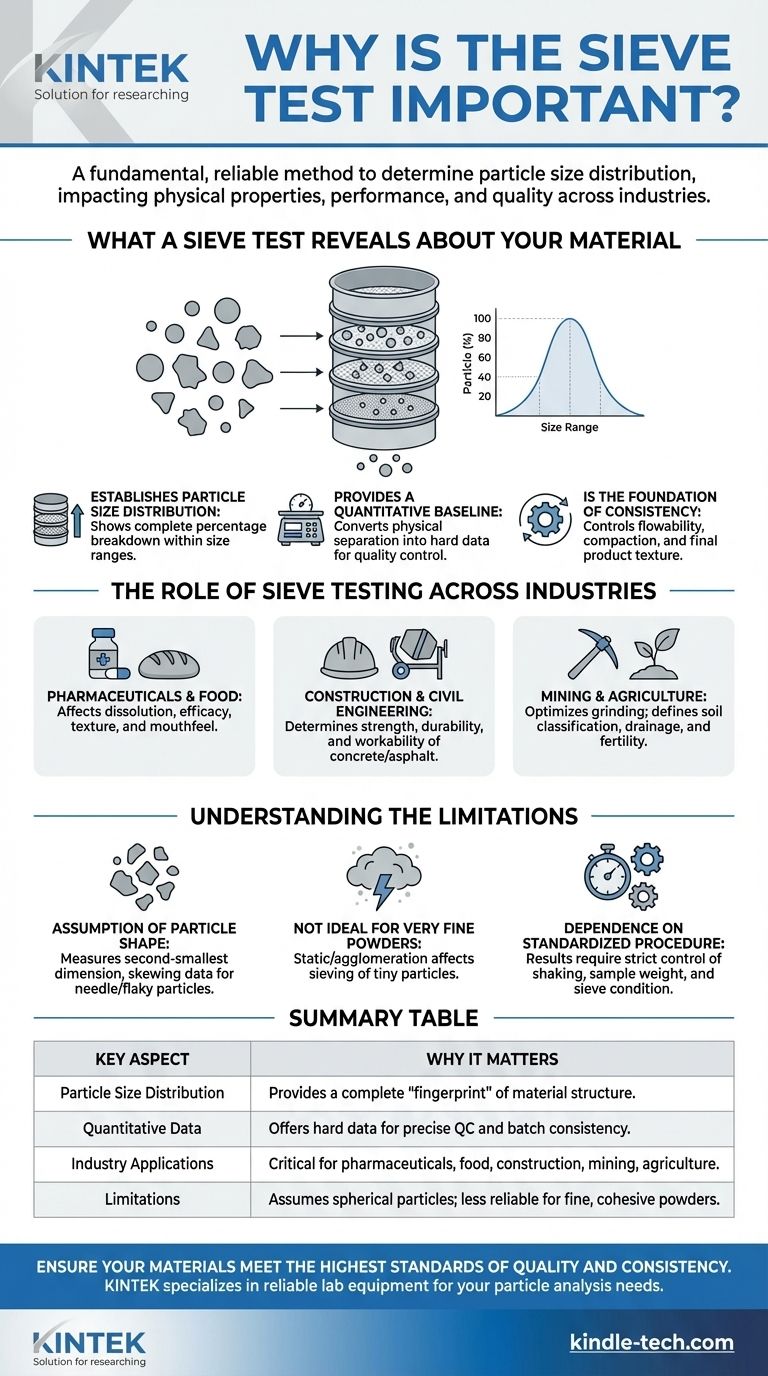

What a Sieve Test Reveals About Your Material

A sieve test, also known as a gradation test, provides a detailed "fingerprint" of your material's particle structure. It moves beyond a simple average size to give a complete picture of the different size fractions within your sample.

It Establishes Particle Size Distribution

A material is rarely composed of uniformly sized particles. A sieve test uses a stack of screens with progressively smaller mesh openings to separate a single sample into multiple size-specific groups.

The result is a particle size distribution curve, a graphical representation showing the percentage of the total sample that falls within each size range.

It Provides a Quantitative Baseline

After shaking the sieve stack, the material retained on each sieve is weighed. This process converts a physical separation into hard data.

This quantitative data is essential for quality control. It allows you to create a precise specification for a material and verify that every batch meets that same standard.

It Is the Foundation of Consistency

By understanding the particle distribution, you can control critical factors that depend on it. This includes flowability, compaction, dissolution rates, and even the texture or appearance of a final product.

Without this data, ensuring batch-to-batch consistency is nearly impossible, leading to unpredictable product quality and performance.

The Role of Sieve Testing Across Industries

The importance of particle size is not theoretical. It has a direct and measurable impact on product value and safety in nearly every sector that handles powders or granular materials.

In Pharmaceuticals and Food

In the pharmaceutical industry, particle size can dictate how quickly an active ingredient dissolves in the body, affecting its efficacy.

In the food industry, the particle size of ingredients like flour, sugar, or spices determines the final product's texture, mouthfeel, and consistency.

In Construction and Civil Engineering

The strength, durability, and workability of concrete and asphalt depend entirely on the precise gradation of the aggregates (sand and gravel) used.

Sieve testing is a mandatory step to ensure these foundational materials meet strict engineering and safety standards.

In Mining and Agriculture

For mining operations, particle size analysis is key to optimizing grinding circuits and maximizing the efficiency of mineral extraction processes.

In agriculture, the distribution of soil particles (sand, silt, and clay) determines its classification, drainage properties, and overall fertility.

Understanding the Limitations

While powerful, the sieve test is not without its limitations. Recognizing these is key to interpreting the results correctly.

The Assumption of Particle Shape

Sieve analysis works by measuring the second-smallest dimension of a particle (the dimension that allows it to pass through a square mesh opening).

This means that long, needle-shaped or flat, flaky particles can pass through a sieve that doesn't accurately represent their true size or volume, potentially skewing the distribution data.

Not Ideal for Very Fine Powders

For extremely fine particles, often found in the pharmaceutical or chemical industries, mechanical sieving becomes less reliable.

These tiny particles can be influenced by static electricity or tend to agglomerate (clump together), preventing them from passing through the mesh correctly. Methods like laser diffraction are often preferred for these materials.

Dependence on Standardized Procedure

Results are only repeatable if the procedure is strictly controlled. Factors like the duration and intensity of shaking, the initial sample weight, and the condition of the sieves themselves can all introduce variability.

Applying This to Your Goal

Your reason for performing a sieve test will determine how you use the data it provides.

- If your primary focus is quality control: Use sieve analysis to establish a definitive particle size specification for incoming raw materials or outgoing finished products to ensure consistency.

- If your primary focus is process optimization: Use the data to understand how changes in your manufacturing process (like milling or grinding) affect the particle distribution and, consequently, the final product's performance.

- If your primary focus is regulatory compliance: Adhere strictly to the sieve testing methods defined by industry standards (e.g., ASTM, ISO) to certify that your material meets all required specifications.

Ultimately, the sieve test is a foundational tool that translates the physical characteristic of particle size into actionable, objective data.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Particle Size Distribution | Provides a complete "fingerprint" of a material's particle structure. |

| Quantitative Data | Offers hard data for precise quality control and batch consistency. |

| Industry Applications | Critical for pharmaceuticals, food, construction, mining, and agriculture. |

| Limitations | Assumes spherical particles; less reliable for very fine, cohesive powders. |

Ensure your materials meet the highest standards of quality and consistency. The data from a sieve test is foundational for product performance. KINTEK specializes in providing reliable lab equipment, including precision sieves and shakers, to meet your particle analysis needs. Let our experts help you select the right equipment for your application. Contact us today to discuss your laboratory requirements!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the primary purpose of an industrial grinder and 400-mesh sieve for coconut shell powder? Achieve Uniformity.

- What is the size range for sieving? From 125mm Gravel to 20µm Powders

- Why is a 100 µm standard test sieve required for LGVO powder? Ensure Smooth Aerosol Deposition and Coating Uniformity

- Which solids can be separated from a solution by sieving? Understanding the Limits of Sieving

- What is the sieve method used for? From Basic Separation to Precise Particle Analysis

- What is the function of stainless steel test sieves? Ensure Accurate Particle Size Analysis

- How do you calculate sieve mesh size? Use Official Standards for Accurate Particle Analysis

- What is the maximum sieving deviation permitted? A Guide to ASTM & ISO Precision Limits