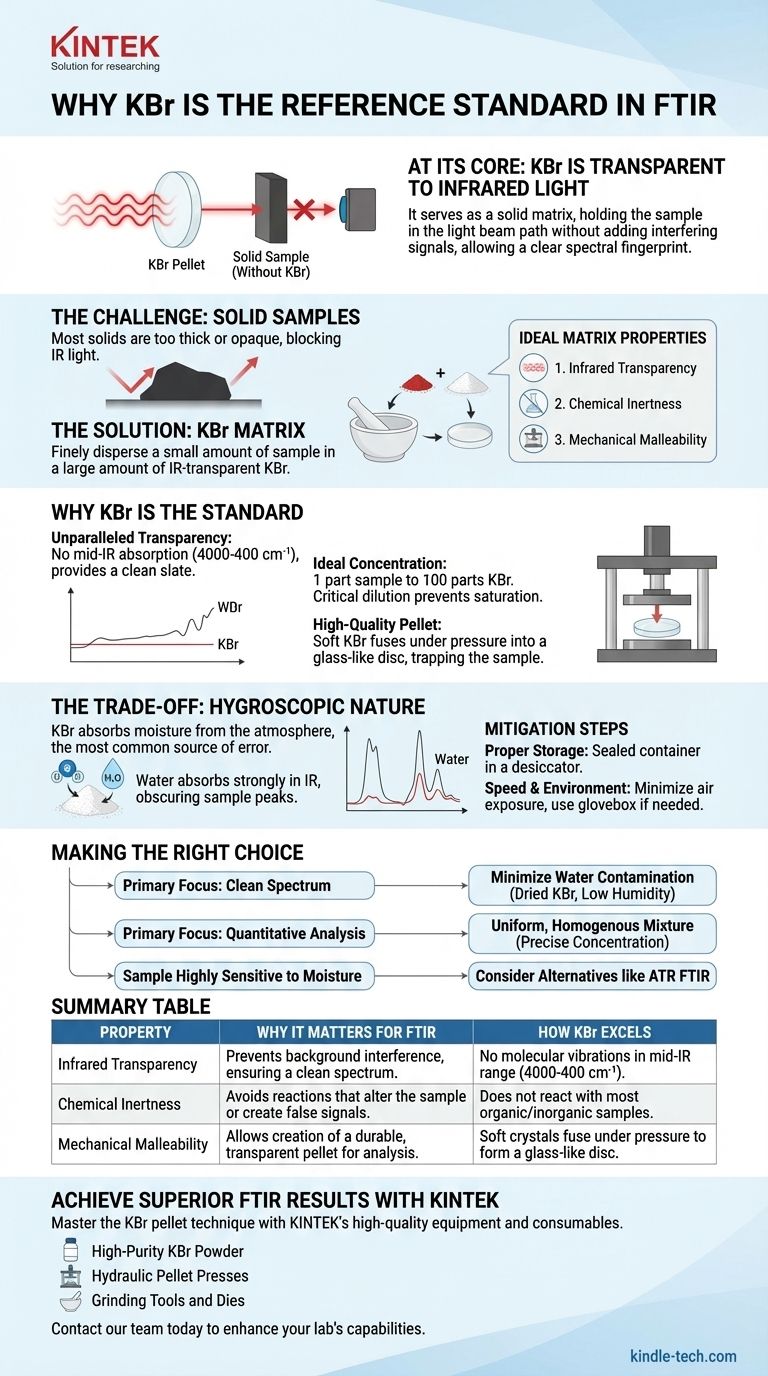

At its core, potassium bromide (KBr) is used in FTIR spectroscopy because it is transparent to infrared light. It serves as a solid matrix, or diluent, that holds the sample in the path of the instrument's light beam without adding any interfering signals of its own. This allows for a clear, unobstructed measurement of the sample's unique spectral fingerprint.

The central challenge in analyzing solid samples with FTIR is getting infrared light to pass through them effectively. KBr solves this by acting as an invisible window; it allows the sample to be diluted and pressed into a transparent pellet, ensuring the resulting spectrum comes purely from the sample and not the material holding it.

The Role of a Matrix in Solid-State FTIR

Why Solid Samples Need a Medium

Most solid materials are too thick or opaque for an infrared beam to pass through directly. If you place a solid chunk in an FTIR spectrometer, it will simply block the light, yielding no useful data.

The goal is to analyze just the right amount of material—enough to generate a strong signal, but not so much that it completely absorbs the light. This is achieved by finely dispersing a small amount of the sample within a larger amount of an IR-transparent medium.

The Ideal Properties of an IR Matrix

An ideal matrix material for this purpose must have several key characteristics:

- Infrared Transparency: It must not absorb light in the mid-infrared region (typically 4000-400 cm⁻¹) where most analysis occurs.

- Chemical Inertness: It must not react with the sample being analyzed.

- Mechanical Malleability: It must be a soft, crystalline material that can be ground into a fine powder and pressed into a durable, transparent disc under pressure.

KBr excels in all three of these areas, making it the industry standard.

Why Potassium Bromide (KBr) is the Standard Choice

Unparalleled Infrared Transparency

KBr is an ionic salt that has no molecular vibrations that absorb energy in the mid-IR range. This complete lack of a background signal ensures that every peak observed in the final spectrum can be attributed solely to the sample material. It provides a perfectly clean slate for analysis.

Creating the Ideal Sample Concentration

The standard preparation involves mixing the sample with KBr powder at a ratio of approximately 1 part sample to 100 parts KBr.

This high level of dilution is critical. It ensures the resulting pellet is not too opaque and that the sample's absorption peaks do not become overly saturated, which would make the data difficult to interpret.

Forming a High-Quality Pellet

After being thoroughly mixed and ground in a mortar and pestle, the KBr/sample mixture is placed into a die and compressed with a hydraulic press. The pressure causes the soft KBr crystals to deform and fuse together, trapping the finely dispersed sample particles within a solid, glass-like pellet that is perfect for analysis.

Understanding the Trade-offs: The Problem with Water

KBr's Hygroscopic Nature

The single most significant drawback of KBr is that it is hygroscopic, meaning it readily absorbs moisture from the atmosphere. This is the most common source of error and poor-quality spectra when using this technique.

How Moisture Interferes with Analysis

Water (H₂O) is a very strong absorber of infrared light, producing broad and intense peaks in the spectrum. If the KBr has absorbed moisture, these water peaks can easily overlap with or completely obscure important peaks from your sample, leading to misinterpretation of the data.

Practical Steps for Mitigation

Managing moisture contamination is non-negotiable for good results.

- Proper Storage: Always store KBr powder in a sealed container inside a desiccator to keep it dry.

- Speed and Environment: Grind the mixture and press the pellet as quickly as possible to minimize air exposure.

- Controlled Atmosphere: In humid environments, performing the preparation inside a glovebox or using a special vacuum die is often necessary to produce a water-free pellet.

Making the Right Choice for Your Goal

Proper KBr technique is essential for acquiring a clean, reliable FTIR spectrum from a solid sample.

- If your primary focus is obtaining a clean, artifact-free spectrum: Your top priority is minimizing water contamination by using properly dried KBr and working in a low-humidity environment.

- If your primary focus is quantitative analysis: Achieving a uniform, homogenous mixture of the sample within the KBr at a precise concentration is absolutely critical for repeatable results.

- If your sample is highly sensitive to moisture: The KBr pellet method may inadvertently introduce water, so consider alternative techniques like Attenuated Total Reflectance (ATR) FTIR if possible.

Ultimately, KBr is an exceptional tool for FTIR analysis, but its effectiveness depends entirely on a careful and deliberate preparation technique.

Summary Table:

| Property | Why It Matters for FTIR | How KBr Excels |

|---|---|---|

| Infrared Transparency | Prevents background interference, ensuring a clean spectrum. | No molecular vibrations in the mid-IR range (4000-400 cm⁻¹). |

| Chemical Inertness | Avoids reactions that could alter the sample or create false signals. | Does not react with most organic and inorganic samples. |

| Mechanical Malleability | Allows creation of a durable, transparent pellet for analysis. | Soft crystals fuse under pressure to form a glass-like disc. |

Achieve Superior FTIR Results with KINTEK

Mastering the KBr pellet technique is key to obtaining clear, reliable FTIR spectra from your solid samples. KINTEK specializes in providing the high-quality laboratory equipment and consumables you need for success.

We supply:

- High-Purity KBr Powder: Minimize moisture contamination for a clean baseline.

- Hydraulic Pellet Presses: Create uniform, transparent pellets with ease.

- Grinding Tools and Dies: Ensure a homogenous sample mixture every time.

Let our expertise support your laboratory's analytical goals. Contact our team today to discuss your specific FTIR needs and discover how KINTEK can enhance your lab's capabilities.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- kbr pellet press 2t

People Also Ask

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy