At its core, a pre-press mold is used to compact loose cannabis material into a dense, uniformly shaped puck before it is placed into a rosin filter bag. This simple preparatory step significantly improves the efficiency and consistency of the rosin extraction process, leading to higher quality yields and less wasted material. By eliminating air pockets and standardizing the material's shape, you ensure optimal heat and pressure distribution during the press.

Inconsistent results in rosin pressing often stem from unevenly packed material, which leads to wasted potential and lower yields. A pre-press mold solves this by creating a standardized starting point, giving you precise control over pressure and heat transfer for a more efficient and predictable extraction every time.

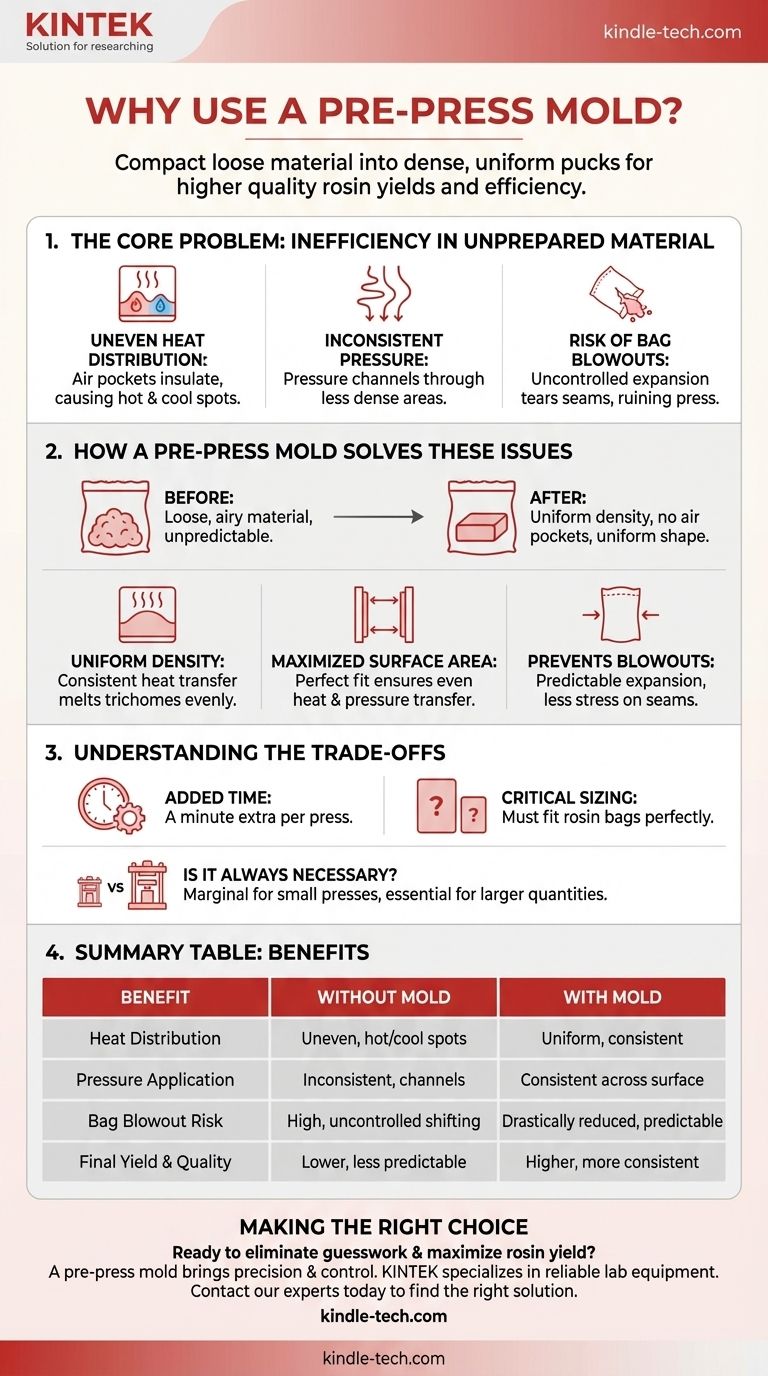

The Core Problem: Inefficiency in Unprepared Material

Without pre-pressing, loose flower or hash is packed directly into a rosin bag. This seemingly minor shortcut introduces several variables that compromise the quality and quantity of your final product.

Uneven Heat Distribution

Loose material contains countless tiny air pockets. Since air is a poor conductor of heat, these gaps act as insulators, preventing the heat from your press plates from penetrating the material evenly. This results in hot spots and cool spots within the bag.

Inconsistent Pressure Application

During pressing, pressure follows the path of least resistance. In a loosely packed bag, some areas are denser than others. The pressure will channel through the less dense areas, leaving the compacted sections under-pressed and their valuable rosin trapped.

The Risk of Bag Blowouts

When heat and pressure are applied, the material shifts and expands. If this expansion is uncontrolled, it can create a single point of high stress on the filter bag's seam, causing it to tear or "blow out." A blowout ruins the press, contaminates your rosin, and wastes material.

How a Pre-Press Mold Solves These Issues

Using a pre-press mold is a deliberate action to remove these variables before the extraction begins. It transforms your starting material from a liability into a consistent asset.

Creating Uniform Density

The primary function of the mold is to compact your material into a solid brick. This process forces out the insulating air pockets, ensuring that the entire mass of cannabis has a consistent density.

This uniform puck allows heat to transfer from the plates and through the material smoothly and evenly, melting the trichome heads at the same rate.

Maximizing Surface Area Contact

A pre-pressed puck is shaped to fit perfectly within the rosin bag. This ensures the material is flush against the interior walls of the filter bag, maximizing surface area contact.

With no gaps between the material and the bag, or the bag and the heated plates, you achieve a far more efficient transfer of both heat and pressure across the entire surface.

Preventing Blowouts and Increasing Yield

By pre-shaping the material, you eliminate uncontrolled shifting during the press. The puck expands predictably, distributing pressure evenly across the bag's seams and drastically reducing the chance of a blowout.

This reliability allows you to apply pressure more confidently. The combination of even heat and consistent pressure ensures that you extract the maximum amount of rosin possible from your starting material.

Understanding the Trade-offs

While highly effective, a pre-press mold is another tool in the process and comes with its own considerations.

The Added Step and Time

Pre-pressing is an additional step in your workflow. While it only takes a minute or two, it adds time to the overall process. For those focused on pure speed over maximum efficiency, this can be seen as a drawback.

Proper Sizing is Critical

Your pre-press mold must be correctly sized for your rosin bags. A mold that is too large will create a puck that strains the bag, while a mold that is too small won't provide the wall-to-wall contact needed for even pressure. This requires a small initial investment and careful selection.

Is It Always Necessary?

For very small, personal-sized presses (e.g., 1-2 grams), the benefits of pre-pressing may be marginal. The natural compression in a small press can sometimes be sufficient. However, as your quantity increases, the efficiency gains from pre-pressing become exponentially more valuable.

Making the Right Choice for Your Goal

Ultimately, the decision to use a pre-press mold depends on your specific objectives.

- If your primary focus is maximizing yield and achieving batch-to-batch consistency: A pre-press mold is an essential tool that removes critical variables from your process.

- If your primary focus is experiencing fewer bag blowouts: A pre-press mold is the most direct and effective solution to this common and costly problem.

- If your primary focus is speed on very small-scale personal presses: You can forgo a pre-press, but you must accept the inherent risk of lower efficiency and potential inconsistencies.

Adopting a pre-press mold is about moving from guesswork to precision, giving you deliberate control over your extraction results.

Summary Table:

| Benefit | Without Pre-Press Mold | With Pre-Press Mold |

|---|---|---|

| Heat Distribution | Uneven, with hot/cool spots | Uniform, for consistent extraction |

| Pressure Application | Inconsistent, follows path of least resistance | Consistent, across entire material surface |

| Bag Blowout Risk | High, due to uncontrolled material shifting | Drastically reduced, with predictable expansion |

| Final Yield & Quality | Lower, less predictable | Higher, more consistent |

Ready to eliminate guesswork and maximize your rosin yield?

A pre-press mold is a simple tool that brings precision and control to your extraction process, preventing costly bag blowouts and ensuring you get the most out of your material.

KINTEK specializes in reliable lab equipment and consumables for precise processing needs. Whether you're refining your personal technique or scaling up production, our expertise can help you achieve consistent, high-quality results.

Contact our experts today to find the right pre-press solution for your setup and start pressing with confidence.

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Assemble Lab Cylindrical Press Mold

- Special Shape Press Mold for Lab

- Ball Press Mold for Lab

- Round Bidirectional Press Mold for Lab

People Also Ask

- What advantages do PTFE molds offer for composite polymer electrolyte casting? Ensure Defect-Free Membrane Fabrication

- What is the role of graphite molds in vacuum hot pressing Mo10/Cu-Al2O3? Optimize Your Advanced Composite Production

- How should KBr powder be pre-treated before it is used to make a pellet? Optimize Your FTIR Spectra Quality

- What role do metal molds play during the cold pressing stage of VC/Cu composite fabrication? High-Precision Shaping

- Why are PEEK mold sleeves and titanium plungers used together? Expert Guide for Solid-State Electrolyte Testing

- Why are a laboratory hydraulic press and precision molds required for pressing MAX phase green bodies? - Expert Guide

- What role do high-strength graphite molds play during vacuum hot pressing? Enhance Precision in CuAlMn Composites

- What roles do high-strength graphite dies play in SPS of WC composites? Optimize Heat & Pressure for Density