Table of Contents

- Introduction to Handheld Precious Metal Analyzers

- Key Features of XRF 990 and XRF 200 Analyzers

- Applications in Jewelry and Precious Metals Industry

- Advantages Over Traditional Testing Methods

- Real-World Case Studies and Success Stories

- Choosing the Right Handheld Precious Metal Analyzer

- Future Trends and Innovations in XRF Technology

Introduction to Handheld Precious Metal Analyzers

Handheld precious metal analyzers are transformative tools that revolutionize the way we test and analyze gold, silver, platinum, and other precious metals. These compact devices leverage cutting-edge technology, such as advanced ceramic packaged microfocus X-ray tubes, high-performance semiconductor detectors, and sophisticated software algorithms, to provide fast, accurate, and non-destructive analysis. Whether you're a jeweler verifying the authenticity of a piece, a recycler ensuring the purity of materials, or a quality control professional in a regulatory agency, these analyzers are your go-to solution for precision and reliability. In this comprehensive guide, we'll delve into the features that make these analyzers stand out, explore their diverse applications across industries, and discuss the advantages they offer over traditional testing methods. From real-world success stories to insights into future trends, this article will equip you with all the knowledge you need to make informed decisions about investing in handheld precious metal analyzers.

Applications in Jewelry and Precious Metals Industry

In the jewelry and precious metals industry, the use of advanced analytical tools such as XRF analyzers is crucial for various applications. These devices are instrumental in ensuring the purity and authenticity of precious metals, which is vital for both consumer trust and regulatory compliance.

Purity Testing in Jewelry

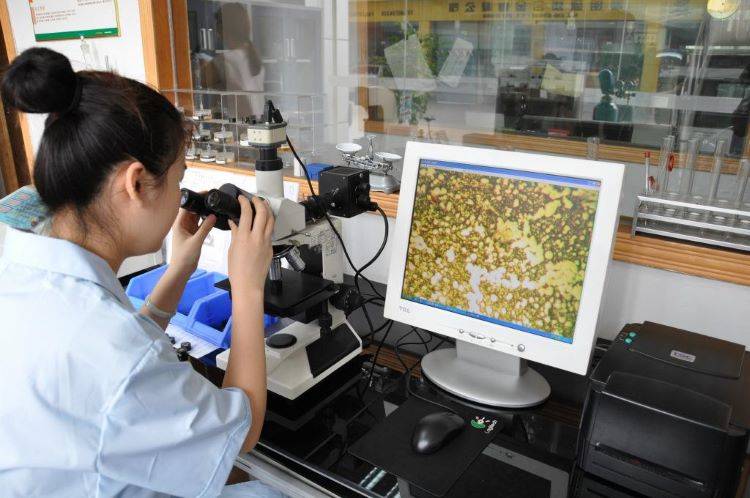

Jewelry retailers and manufacturers rely heavily on XRF analyzers to test the purity of gold, silver, platinum, and other precious metals. These devices can quickly and accurately determine the karat value of gold items, ensuring that the products meet the advertised standards. For instance, the XRF 200 benchtop gold analyzer allows for precise measurement of precious metal content in seconds, displaying results on a bright color touchscreen. This technology is also beneficial for distinguishing between genuine gold and counterfeit items, such as gold-plated jewelry, by detecting the presence of coatings or plating.

Authenticity Checks in Pawnshops

Pawnshops and cash-for-gold operations use XRF analyzers to verify the authenticity and purity of gold and other precious metals. This helps in making informed purchasing decisions and prevents the sale of fraudulent items. The XRF 990 handheld precious metal analyzer, for example, offers a non-destructive testing method that is safe for both the operator and the jewelry. It can quickly identify the purity of gold and silver jewelry, as well as investment gold, ensuring that pawnshops can confidently assess the value of items brought in by customers.

Quality Inspections in Regulatory Agencies

Regulatory agencies responsible for overseeing the jewelry industry also utilize XRF analyzers for quality inspections. These agencies ensure that jewelry sold to the public meets specific purity standards. The XRF technology allows for rapid and accurate testing, which is essential for maintaining high standards in the industry. It helps in identifying the purity of precious metals like gold and silver, ensuring that they comply with legal requirements.

Recycling of Precious Metals

The recycling of precious metals is another significant application of XRF analyzers. In the gold refining industry, these devices are used to monitor the concentration of gold in activated carbon. They are also crucial in testing precious metals such as platinum, rhodium, and palladium in the recovery of automobile three-way catalysts. Additionally, XRF analyzers are employed in the analysis of recycled precious metal catalysts used in the chemical industry, including metals like platinum, palladium, ruthenium, rhodium, and iridium. This precise analysis ensures the quality and efficiency of the recycling process, contributing to the sustainability of the precious metals industry.

Analysis of Industrial Catalysts

Industrial catalysts, particularly those used in chemical processes, often contain precious metals. XRF analyzers play a vital role in analyzing these catalysts to ensure they contain the correct concentration of precious metals. This is crucial for maintaining the efficiency and effectiveness of industrial processes. The non-destructive nature of XRF testing also means that the catalysts can be reused after testing, reducing waste and costs.

In conclusion, XRF analyzers are indispensable tools in the jewelry and precious metals industry, offering fast, accurate, and non-destructive testing capabilities. They are essential for maintaining the integrity of precious metal products, ensuring consumer safety, and facilitating efficient recycling and industrial processes.

Advantages Over Traditional Testing Methods

Handheld XRF analyzers offer significant advantages over traditional methods like nitric acid testing and fire assay, particularly in terms of speed, accuracy, and safety. Traditional methods often require extensive sample preparation, which can be time-consuming and may alter the sample, potentially affecting the accuracy of the results. Fire assay, for instance, involves melting the sample, which is not only destructive but also poses safety risks due to the high temperatures and hazardous chemicals involved.

In contrast, handheld XRF analyzers provide rapid, non-destructive analysis. With advanced electronics and sophisticated mathematical algorithms, these devices can deliver lab-quality results within seconds. This speed is crucial in various applications, such as incoming material inspection, finished goods analysis, and in-process production checks. The ability to obtain results quickly enhances decision-making processes and can significantly improve operational efficiency.

Moreover, the non-destructive nature of XRF technology preserves sample integrity, which is particularly important when the sample is rare or valuable. This preservation allows for further testing if required and ensures that the sample remains intact for future reference or additional analyses. Safety is another critical advantage; XRF analyzers eliminate the need for handling dangerous chemicals and reduce the risk of accidents associated with high-temperature processes.

Accuracy is also enhanced with handheld XRF analyzers. They are designed to provide reliable and precise measurements, often achieving results comparable to fire assay but with greater ease and safety. This accuracy is crucial in preventing losses from under-karated or counterfeit materials, especially in industries dealing with precious metals and scrap metal recycling.

In summary, handheld XRF analyzers represent a significant advancement over traditional testing methods. They offer faster, safer, and more accurate results, all while preserving the integrity of the sample. These benefits make XRF technology an indispensable tool in various industries, from quality control in manufacturing to precious metal analysis and scrap metal sorting.

Real-World Case Studies and Success Stories

In the realm of jewelry retail, precious metal refining, and analytical laboratories, XRF analyzers have emerged as transformative tools, significantly enhancing operational efficiency and customer trust. Here are some compelling case studies that highlight their impact:

Jewelry Retailers

One notable example is a prominent jewelry retailer that implemented the XRF 200 benchtop gold analyzer. This retailer experienced a substantial improvement in customer satisfaction and operational efficiency. By accurately measuring the precise content of precious metals in jewelry, coins, and other valuable items within seconds, the retailer was able to provide immediate and reliable information to customers. This not only enhanced the customer experience but also reduced the reliance on external testing services, thereby saving time and reducing costs.

Precious Metal Refiners

A precious metal refiner faced challenges in accurately assessing the purity of materials, which was critical for their business operations. The introduction of handheld XRF analyzers revolutionized their process. These analyzers allowed for swift qualitative screenings directly in the field, enabling the refiner to minimize the unpredictability of excavation and reduce the necessity of outsourcing samples to external testing labs. The rapid assays provided by the XRF analyzers optimized their extraction processes and determined ore grade, leading to significant cost savings and improved productivity.

Analytical Laboratories

Analytical laboratories have also benefited immensely from the integration of XRF technology. A laboratory specializing in geochemical testing and mapping adopted AXR analyzers, which offered rapid assays for optimizing drill locations and guiding extraction processes. The intelligent software of these analyzers, with features like remote operation and seamless data transfer, streamlined the laboratory's workflow. This resulted in reduced turnaround times and laboratory expenses, while also boosting the confidence in the data accuracy.

These case studies underscore the transformative impact of XRF analyzers across various sectors. By providing rapid, accurate, and non-destructive analysis, these tools have not only improved operational efficiency but have also fostered a greater level of trust among customers and stakeholders. The ability to conduct real-time analysis in the field or laboratory setting has proven invaluable, leading to optimized processes, cost savings, and enhanced customer satisfaction.

Choosing the Right Handheld Precious Metal Analyzer

Selecting the appropriate handheld precious metal analyzer is crucial for ensuring accurate and efficient analysis of precious metals. Key factors to consider include analytical performance, ease of use, and the support services offered by manufacturers.

Analytical Performance

The analytical performance of a handheld precious metal analyzer is paramount. Devices like the XRF 990 utilize advanced ceramic packaged microfocus X-ray tubes and high-performance semiconductor detectors. These technologies enable quick, accurate, and non-destructive testing of gold, silver, platinum, and other precious metals. The analyzer's ability to detect gold plating, including gold-plated silver, copper, steel, and tungsten, is also essential for identifying counterfeit materials.

Ease of Use

Ergonomic design and user-friendly interfaces are significant considerations. Analyzers such as the XRF 200 are designed for practicality, with features like a closed-beam design to prevent x-ray exposure and a vibrant touch-screen color monitor that displays results within seconds. The compact and portable design, along with optional accessories like a small spot collimator and an external portable printer, enhance the device's usability in various settings, from retail environments to pawnshops.

Support Services

Manufacturers' support services are crucial for maintaining the efficiency and longevity of the analyzer. Services may include factory calibration, technical support, and software updates. Ensuring that the analyzer is ready for use upon arrival and that there is ongoing support for any technical issues can significantly impact the device's effectiveness and reliability.

Applications

Handheld precious metal analyzers are versatile tools with applications ranging from jewelry authenticity identification and purity analysis to industrial uses such as monitoring gold concentration in activated carbon and testing precious metals in automobile catalysts. The ability to non-destructively test samples, preserving their original state, is particularly beneficial in industries where material integrity is crucial.

Conclusion

Choosing the right handheld precious metal analyzer involves careful consideration of its analytical capabilities, user interface, and the support provided by the manufacturer. By selecting a device that aligns with specific needs, such as the XRF 990, users can ensure reliable, precise, and efficient analysis of precious metals, enhancing decision-making and operational efficiency in various sectors.

Future Trends and Innovations in XRF Technology

The field of XRF (X-ray Fluorescence) technology continues to evolve, driven by advancements in detector technology, software algorithms, and integration with other analytical tools. These innovations are not only enhancing the capabilities of handheld precious metal analyzers but also expanding their applications across various industries.

One of the most significant trends in XRF technology is the development of more sophisticated detectors. Modern detectors are designed to be more sensitive and accurate, capable of detecting even the smallest traces of elements. This improvement is crucial for applications in precious metal analysis, where the detection of minute quantities can significantly impact the value of the materials being tested. For instance, the ability to accurately measure gold content in jewelry or in mining operations can prevent losses from under-karated or counterfeit materials.

Software algorithms are another area where substantial progress is being made. Advanced algorithms are being developed to improve the speed and accuracy of data analysis. These algorithms can process complex data sets quickly, providing results in real-time. This capability is particularly beneficial in dynamic environments such as mining sites or scrap yards, where rapid decision-making is essential. The integration of machine learning and artificial intelligence into these algorithms is also opening up new possibilities for predictive analytics, enabling users to forecast trends and optimize processes based on historical data.

Integration with other analytical tools is another emerging trend in XRF technology. By combining XRF with techniques such as optical emission spectroscopy or mass spectrometry, analysts can obtain a more comprehensive understanding of the materials they are testing. This multi-technique approach can provide more detailed elemental composition data, which is invaluable for applications in geology, environmental science, and industrial quality control.

Looking ahead, the future of XRF technology appears promising, with potential applications in areas such as environmental monitoring, pharmaceutical quality control, and even space exploration. As detector technology continues to improve and software algorithms become more sophisticated, the capabilities of handheld XRF analyzers will expand, making them an indispensable tool for a wide range of industries. The ongoing integration with other analytical technologies will also continue to enhance the versatility and utility of XRF systems, ensuring their relevance in the ever-evolving landscape of scientific and industrial analysis.

Related Products

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- XRD Sample Holder X-ray Diffractometer Powder Slide

- Platinum Auxiliary Electrode for Laboratory Use

Related Articles

- Comprehensive Guide to Rotating Disk Electrode (RDE) in Electrochemical Studies

- Advanced Techniques in Coating Evaluation Using Electrolytic Cells

- Understanding Saturated Calomel Reference Electrodes: Composition, Uses, and Considerations

- Ultimate Guide to Handheld Alloy Analyzers: Features, Applications, and Advantages

- The Architecture of Certainty: Mastering Control in Multifunctional Electrolytic Cells