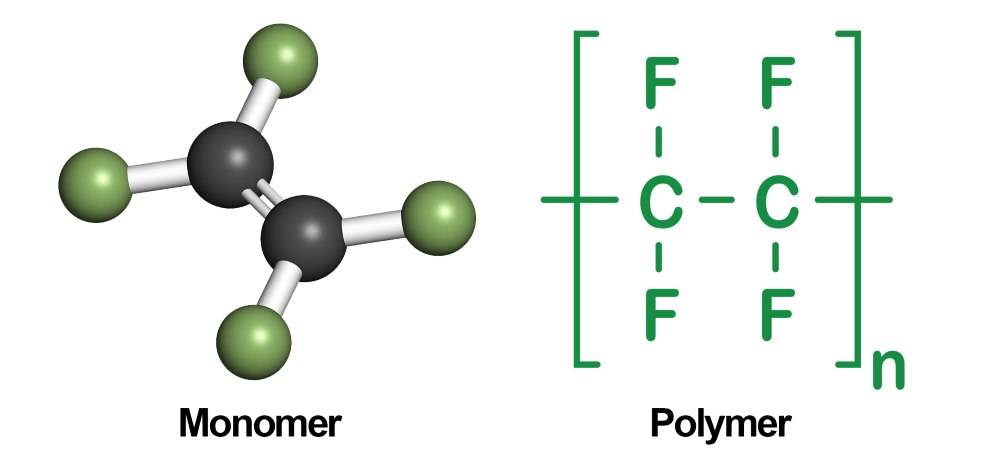

I. Molecular structure and chemical stability

PTFE molecule consists of a carbon chain backbone and tightly wrapped fluorine atoms. The high electronegativity of the fluorine atom and the lone pair of electrons form a layer of non-polar "fluorine sheath", making it a poor electron donor or hydrogen bond acceptor. This structure gives PTFE excellent chemical inertness, virtually non-reactive with any acids, bases, organic solvents, and even resistant to aqua regia and strong oxidizing agents. The only exceptions are molten alkali metals (such as sodium) and liquid fluorine, which makes PTFE the material of choice for corrosion-resistant linings and seals for chemical equipment.

II. Excellent temperature resistance

PTFE has an extremely wide range of temperature resistance, long-term use of the temperature covers -196 ° C to 260 ° C, short-term can withstand high temperatures of 300 ° C. The temperature resistance of PTFE is due to its high bonding capacity , which is due to the fact that it can withstand high temperatures. Its heat resistance stems from its high bonding C-F structure, which does not decompose or release harmful substances even at high temperatures. This property makes it suitable for extreme environments, such as aerospace high temperature seals, chemical high temperature reactor linings, etc.

III. Ultra-low friction and self-lubrication

PTFE has a coefficient of friction of only 0.04, one of the lowest of any known solid material, and very low surface energy. This characteristic makes it in the oil-free lubrication conditions can still maintain excellent performance, widely used in bearings, guide rails, seals and other fields. Studies have also shown that PTFE forms a transfer film during friction, further reducing the wear and tear of the dyadic material.

IV. Non-stick and surface inert

PTFE surface tension is extremely low (about 18.5 mN / m), almost does not adhere to any substance. This property has not only given rise to civilian products such as non-stick pan coatings, but is also used in medical catheter liners to prevent biological tissues from sticking. In industry, nonstick makes PTFE ideal for filter membranes and antifouling coatings.

V. Excellent electrical insulation properties

As a class C insulating material, PTFE has a low dielectric constant (2.1), low dielectric loss and remains stable in high temperature, high humidity and corrosive environments. This advantage makes it widely used in high-frequency communication cable insulation, semiconductor manufacturing equipment seals and other high-end electronic fields.

VI. Biocompatibility and medical applications

PTFE is physiologically inert, long-term implantation in the human body (such as artificial blood vessels) will not cause rejection. Its chemical stability also ensures that medical catheter components do not react with body fluids in the body, reducing the risk of infection. In addition, in the pharmaceutical industry, PTFE seals can avoid contamination in drug production.

VII. Can be modified to expand the boundaries of the application

Although pure PTFE mechanical strength is low, but through the filling of glass fibers, carbon fibers or graphite and other materials, can significantly improve its wear resistance, thermal conductivity and resistance to compression deformation. For example, filler-modified PTFE seals can work stably in high-pressure environments; seals compounded with rubber are both elastic and corrosion-resistant.

VIII. Examples of multi-discipline applications

- Chemical field: pipeline lining, valve sealing, resistance to strong acids and alkalis;

- Electrical and electronic: high-frequency circuit boards, insulating bushings;

- Medical equipment: catheters, artificial organs;

- Aerospace: high-temperature-resistant seals, fuel system components;

- Food Processing: non-stick molds, conveyor belts, coatings.

Conclusion

With its unique molecular structure, PTFE builds core advantages such as corrosion resistance, extreme temperature resistance, and low friction. With the advancement of material modification technology, its application areas are expanding. From rocket engines to artificial heart valves, PTFE continues to push the boundaries of modern industry and technology, and can be called an exemplary work of materials science.

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Custom PTFE Teflon Parts Manufacturer for PTFE Ball Valve Seat

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

Related Articles

- Polytetrafluoroethylene (PTFE): How low friction coefficient promotes industrial progress

- Versatile Applications of PTFE Cleaning Racks: Enhancing Laboratory Efficiency and Precision

- PTFE's high temperature and corrosion resistance: Why it is indispensable in industry

- PTFE Cleaning Racks: The Ultimate Guide to Cleaning and Drying Labware

- PTFE seals: the invisible guardian of industrial leakage prevention