In short, yes. Ceramic implants are almost always more expensive than their titanium counterparts. The price difference can range from several hundred to over a thousand dollars per implant, depending on the manufacturer, the complexity of the case, and the dental practice's fee structure.

The decision between ceramic and titanium is not just about the upfront cost. It's a strategic choice between the superior aesthetics and metal-free properties of ceramic versus the proven long-term track record, versatility, and cost-effectiveness of titanium.

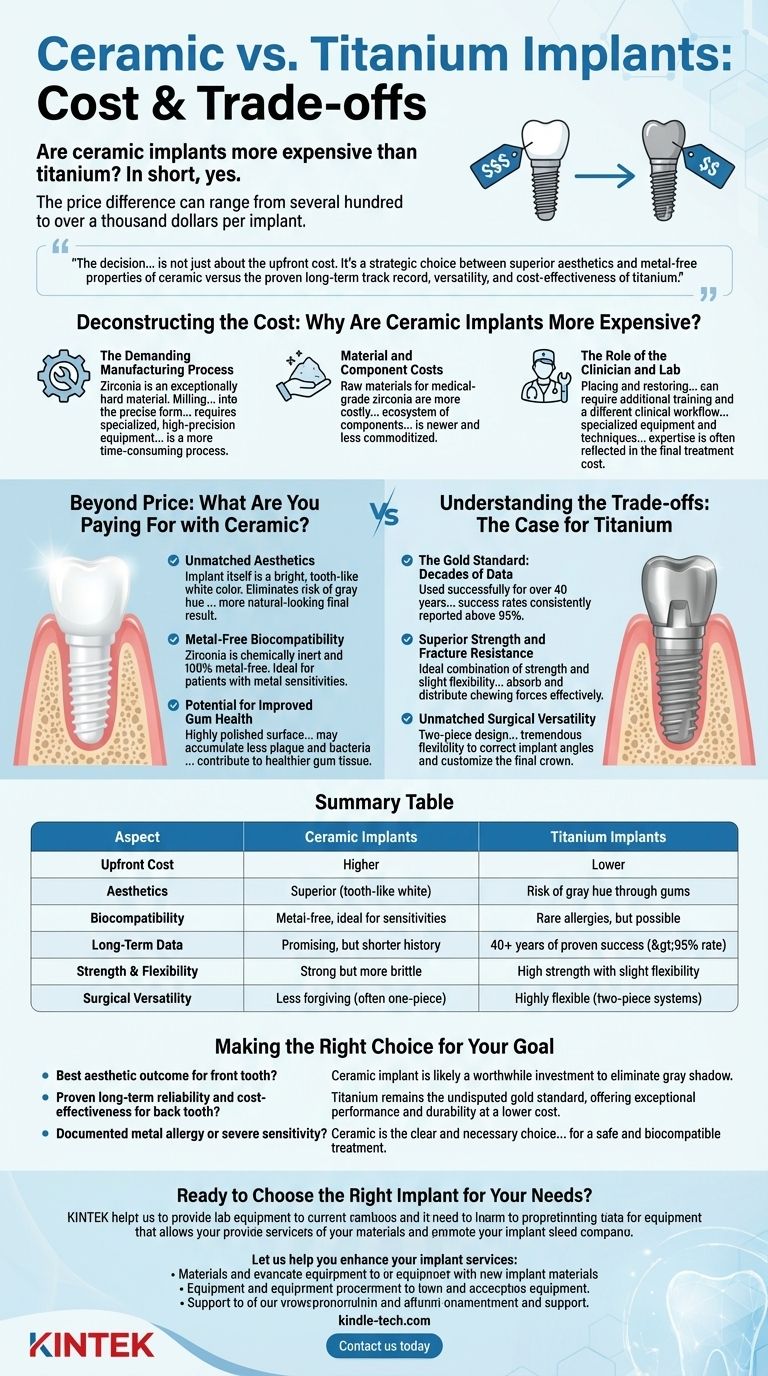

Deconstructing the Cost: Why Are Ceramic Implants More Expensive?

The higher price of ceramic implants is not arbitrary. It is rooted in tangible differences in materials, manufacturing, and clinical application.

The Demanding Manufacturing Process

Zirconia, the high-performance ceramic used for these implants, is an exceptionally hard material.

Milling and shaping zirconia into the precise, complex form of a dental implant requires specialized, high-precision equipment and is a more time-consuming process than machining titanium. This increased manufacturing complexity directly translates to a higher cost.

Material and Component Costs

The raw materials for medical-grade zirconia are more costly to procure and process than those for titanium alloy.

Furthermore, the ecosystem of components for ceramic implants is newer and less commoditized. While titanium systems have a wide array of standardized and competitively priced parts (like abutments), the components for ceramic systems are often proprietary and carry a premium.

The Role of the Clinician and Lab

Placing and restoring ceramic implants can require additional training and a different clinical workflow compared to the well-established titanium protocols.

The dentist and dental laboratory may invest in specialized equipment and techniques to handle the material properly, and this expertise is often reflected in the final treatment cost.

Beyond Price: What Are You Paying For with Ceramic?

The premium for ceramic implants buys you a distinct set of benefits, centered primarily on aesthetics and biocompatibility.

Unmatched Aesthetics

This is the number one reason patients choose ceramic. The implant itself is a bright, tooth-like white color.

For patients with thin gum tissue, especially in the front of the mouth (the "aesthetic zone"), a titanium implant can sometimes create a subtle gray hue visible through the gums. A ceramic implant completely eliminates this risk, ensuring a more natural-looking final result.

Metal-Free Biocompatibility

Zirconia is chemically inert and 100% metal-free. While titanium allergies are exceedingly rare, they can be a concern for a small subset of the population with known metal sensitivities.

For these patients, a ceramic implant is not just an option but a necessity, providing a highly biocompatible solution that integrates well with bone and soft tissue.

Potential for Improved Gum Health

Some clinical research suggests that the highly polished surface of zirconia may accumulate less plaque and bacteria compared to titanium surfaces.

While not definitively proven to result in better long-term outcomes in all cases, this property is believed to contribute to healthier gum tissue around the implant.

Understanding the Trade-offs: The Case for Titanium

Choosing ceramic means forgoing some of the key advantages that have made titanium the default choice for decades.

The Gold Standard: Decades of Data

Titanium implants have been used successfully for over 40 years. Their long-term performance is supported by a vast body of scientific literature, with success rates consistently reported above 95% over 10 years and beyond.

Ceramic implants have a much shorter history. While current data is very promising, they simply do not have the same depth of long-term, multi-decade clinical evidence that titanium does.

Superior Strength and Fracture Resistance

Titanium possesses an ideal combination of strength and slight flexibility. This allows it to absorb and distribute chewing forces effectively without breaking.

Modern zirconia is incredibly strong, but it is also more brittle than titanium. This means it has a lower resistance to fracture. While implant fractures are rare for both materials, the risk is historically higher with ceramic, particularly in older designs or smaller-diameter implants.

Unmatched Surgical Versatility

Most titanium implants use a two-piece design: the implant that goes in the bone and a separate connector piece called an abutment. This gives the surgeon and restorative dentist tremendous flexibility to correct implant angles and customize the final crown.

Many ceramic implants utilize a one-piece (monolithic) design, which can be less forgiving. The implant's position must be surgically perfect, as there is little to no room for post-surgical angle correction. While two-piece ceramic systems exist, they are newer and less common.

Making the Right Choice for Your Goal

The final decision should be made in consultation with your implant surgeon, weighing the costs against your specific clinical needs and aesthetic desires.

- If your primary focus is the absolute best aesthetic outcome for a front tooth: The extra cost of a ceramic implant is likely a worthwhile investment to eliminate any risk of a gray shadow.

- If your primary focus is proven long-term reliability and cost-effectiveness, especially for a back tooth: Titanium remains the undisputed gold standard, offering exceptional performance and durability at a lower cost.

- If you have a documented metal allergy or severe sensitivity: Ceramic is the clear and necessary choice to ensure a safe and biocompatible treatment.

Ultimately, both materials are excellent solutions, and understanding their unique cost-benefit profiles empowers you to choose the one that best aligns with your health and financial priorities.

Summary Table:

| Aspect | Ceramic Implants | Titanium Implants |

|---|---|---|

| Upfront Cost | Higher | Lower |

| Aesthetics | Superior (tooth-like white) | Risk of gray hue through gums |

| Biocompatibility | Metal-free, ideal for sensitivities | Rare allergies, but possible |

| Long-Term Data | Promising, but shorter history | 40+ years of proven success (>95% rate) |

| Strength & Flexibility | Strong but more brittle | High strength with slight flexibility |

| Surgical Versatility | Less forgiving (often one-piece) | Highly flexible (two-piece systems) |

Ready to Choose the Right Implant for Your Needs?

Navigating the choice between ceramic and titanium implants requires expert guidance tailored to your unique clinical and aesthetic goals. At KINTEK, we specialize in providing high-quality dental laboratory equipment and consumables that support precise implant manufacturing and restoration workflows. Whether your practice focuses on cutting-edge ceramic solutions or relies on the proven performance of titanium, our products help ensure accuracy, efficiency, and outstanding patient outcomes.

Let us help you enhance your implant services:

- Access reliable materials for both ceramic and titanium workflows

- Benefit from equipment designed for precision and durability

- Receive support tailored to laboratory and clinical needs

Contact us today to learn how KINTEK can support your practice with the tools and expertise needed for successful implant treatments.

Visual Guide

Related Products

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

- High Temperature Alumina (Al2O3) Furnace Tube for Engineering Advanced Fine Ceramics

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- What are the applications of zirconia ceramics? Unlock High-Performance Solutions for Extreme Environments

- What are the technical advantages of using zirconia (ZrO2) grinding balls? Enhancing Silicon Composite Anode Performance

- Why are ZrO2 grinding jars and balls required for sulfide solid electrolytes? Ensure Purity & Performance

- What are the advantages of using zirconia milling jars for sulfide electrolytes? Enhance Purity and Conductivity

- What are alloys in simple words? Unlock the Power of Engineered Materials