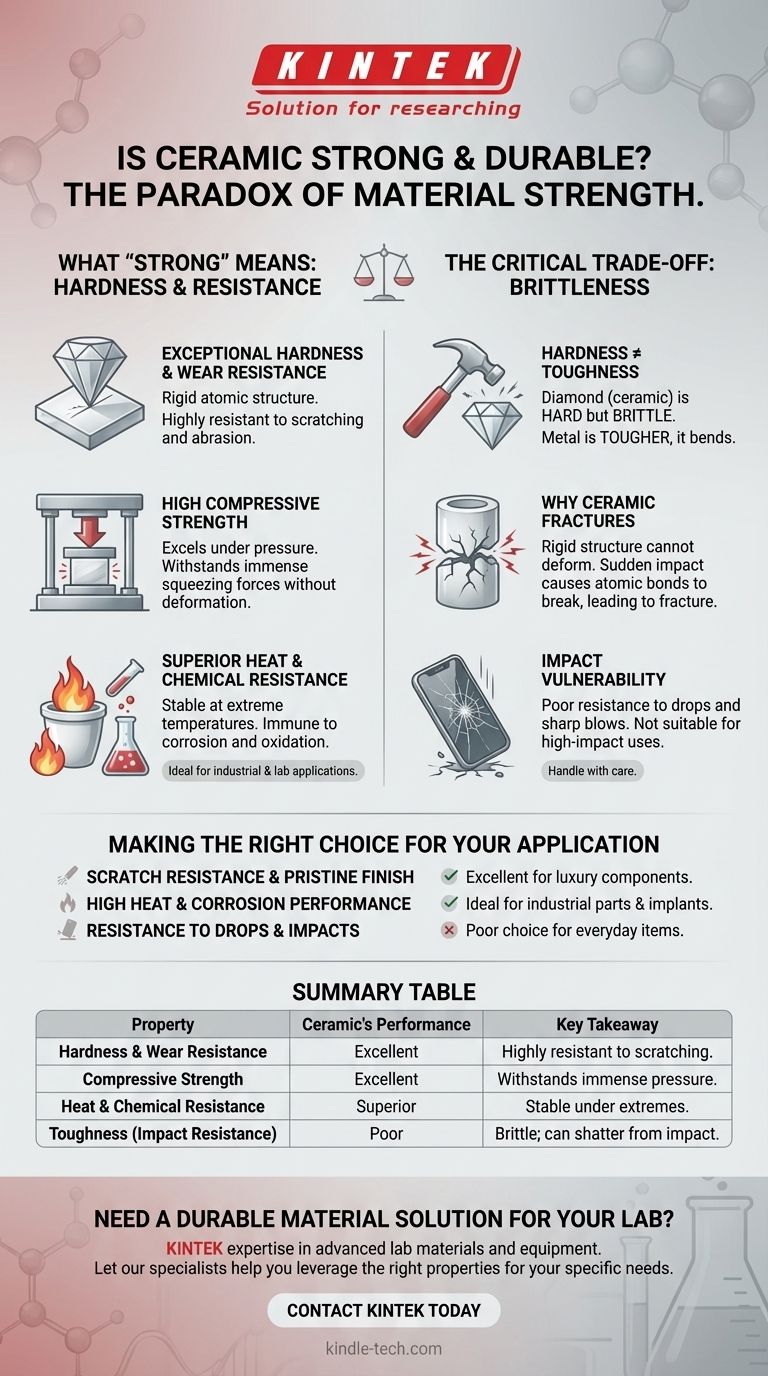

In the world of materials, the strength of ceramic is a paradox. Yes, advanced ceramics are incredibly strong and durable, but in a very specific way. They possess immense hardness and resistance to heat, wear, and corrosion due to their powerful atomic bonds, making them last for decades under the right conditions.

The core takeaway is that ceramic's durability comes from its exceptional hardness and resistance to compression, not from its ability to withstand impacts. While it is one of the most wear-resistant materials available, it is also inherently brittle and can shatter from a sharp blow.

What "Strong" Means for Ceramic

The term "strong" can be misleading. For ceramic materials, strength is defined by a unique set of properties that make them superior in certain environments but vulnerable in others.

Exceptional Hardness and Wear Resistance

The primary strength of ceramic is its incredible hardness. The strong ionic and covalent bonds that hold ceramic atoms together create a highly rigid structure that is extremely difficult to scratch or wear down.

This makes it one of the most durable materials for applications where surface abrasion is the main concern.

High Compressive Strength

Ceramics excel under compression. They are exceptionally strong when being squeezed or pushed, able to withstand immense pressure without deforming.

This property is why ceramics are used in applications like armor plating and industrial bearings.

Superior Heat and Chemical Resistance

Durability isn't just about physical force. Ceramics are highly resistant to extreme temperatures and are virtually immune to corrosion and oxidation.

They do not rust or degrade when exposed to harsh chemicals, contributing to their exceptional long-term stability and lifespan.

Understanding the Critical Trade-Off: Brittleness

The very properties that make ceramic so hard also create its primary weakness. Its strength is not universal, and understanding its limitations is crucial.

The Difference Between Hardness and Toughness

It's vital to distinguish between hardness (resistance to scratching) and toughness (resistance to fracture). A diamond is extremely hard and can scratch steel, but a steel hammer can easily shatter the diamond.

Ceramic is like the diamond: exceptionally hard, but not tough. Metals, by contrast, are often tougher and will dent or bend rather than shatter under impact.

Why Ceramic Can Fracture

The rigid atomic structure of ceramic does not allow for deformation. When a ceramic object is subjected to a sharp, sudden impact, the energy has nowhere to go.

Instead of bending, the atomic bonds break, causing the material to fracture or shatter. This property is known as brittleness.

Making the Right Choice for Your Application

Whether ceramic is "strong" and "durable" enough depends entirely on its intended use.

- If your primary focus is scratch resistance and a pristine finish: Ceramic is an excellent choice for items like watch cases or luxury components where avoiding wear is paramount.

- If your primary focus is performance under high heat or corrosion: Ceramic is an ideal material for industrial parts, engine components, or medical implants due to its stability.

- If your primary focus is resistance to drops and impacts: Ceramic is a poor choice for applications like phone cases or everyday cookware where sudden shocks are likely.

Understanding this balance between extreme hardness and inherent brittleness is the key to leveraging ceramic's remarkable properties correctly.

Summary Table:

| Property | Ceramic's Performance | Key Takeaway |

|---|---|---|

| Hardness & Wear Resistance | Excellent | Highly resistant to scratching and abrasion. |

| Compressive Strength | Excellent | Withstands immense pressure without deforming. |

| Heat & Chemical Resistance | Superior | Stable under extreme temperatures and harsh chemicals. |

| Toughness (Impact Resistance) | Poor | Brittle; can shatter from a sharp blow or impact. |

Need a durable material solution for your lab?

At KINTEK, we understand that material selection is critical to your success. Whether your application demands extreme heat resistance, unparalleled hardness, or chemical inertness, our expertise in advanced lab materials and equipment can help you make the right choice.

We provide high-quality materials and consumables tailored to the unique challenges of laboratory environments. Let our specialists help you leverage the right properties for your specific needs.

Contact KINTEK today to discuss your project and discover how our solutions can enhance your lab's performance and durability.

Visual Guide

Related Products

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

People Also Ask

- What are the properties of ceramic surfaces? Discover Their Extreme Hardness and Stability

- What role does a carbon template play in nanocasting magnesium oxide? Master Porous Material Precision

- Are there any disadvantages of ceramics? The Trade-Off Between Hardness and Brittleness

- What industry uses ceramics? Discover the Critical Role of Advanced Ceramics in Modern Technology

- Why is alumina used in furnaces? Achieve Unmatched Heat Resistance and Purity

- What is the use of SiC semiconductor? Unlock Higher Efficiency for EVs and Power Systems

- What is the primary purpose of using zirconia coatings in W-Cu infiltration? Ensure Dense, Void-Free Composites

- Why is sintering important in ceramic processing? Achieve Dense, High-Performance Ceramic Parts