In short, yes. A CVD diamond is a real diamond in every sense that matters scientifically. It possesses the exact same chemical structure, physical hardness, and optical brilliance as a diamond mined from the Earth. The United States Federal Trade Commission (FTC) officially ruled in 2018 that lab-grown diamonds are not "synthetics" or "simulants" but are, in fact, diamonds.

The only fundamental difference between a CVD diamond and a mined diamond is its origin. One is created in a controlled laboratory environment, while the other was formed by geological processes over billions of years. Chemically and visually, they are identical.

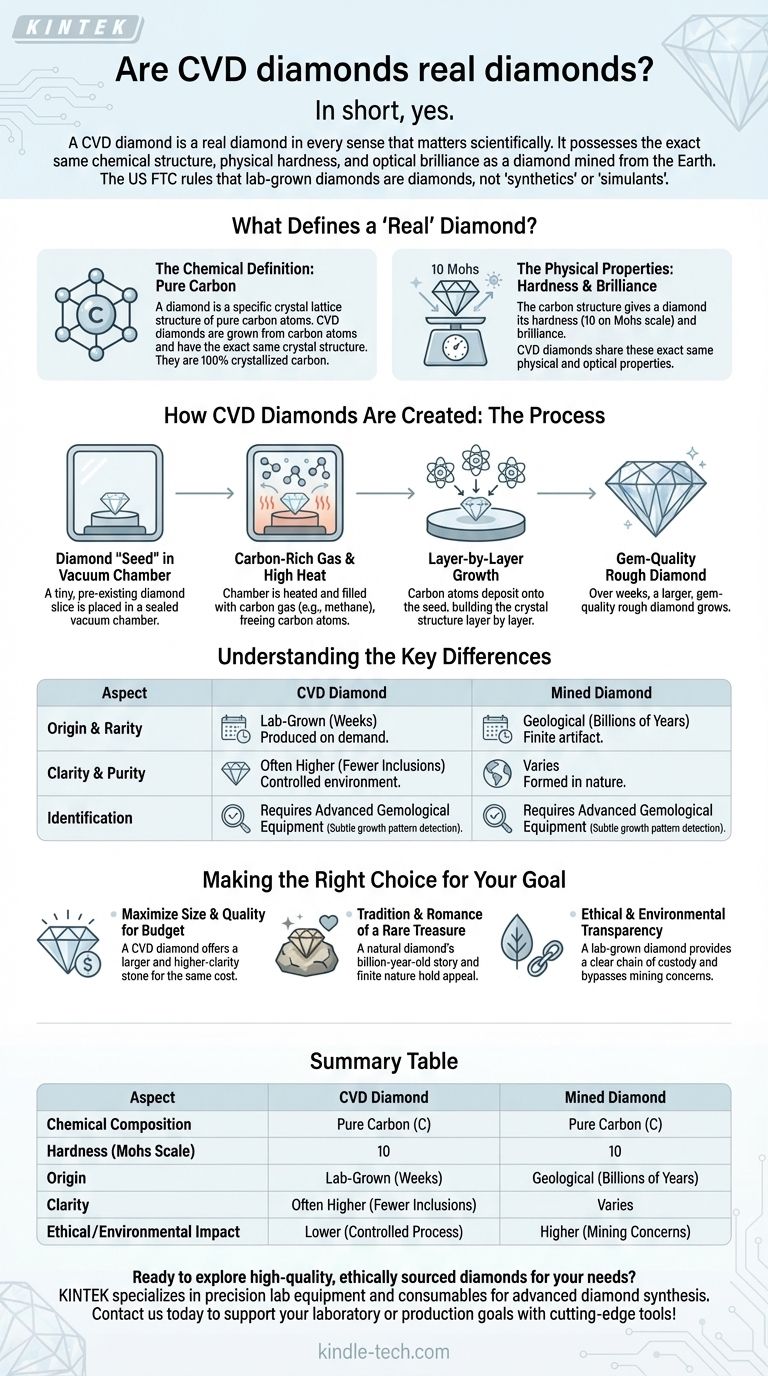

What Defines a "Real" Diamond?

To understand why CVD diamonds are considered real, we must first define what a diamond is at its core. It isn't about origin; it's about material composition and structure.

The Chemical Definition: Pure Carbon

A diamond is a specific crystal lattice structure of pure carbon atoms. This rigid, interlocking atomic arrangement is what makes a diamond a diamond.

CVD diamonds are grown from carbon atoms and have the exact same crystal structure as their mined counterparts. They are 100% crystallized carbon.

The Physical Properties: Hardness and Brilliance

The unique carbon structure gives a diamond its famous properties: a perfect 10 on the Mohs scale of hardness and an exceptional ability to refract and disperse light, creating its signature fire and brilliance.

Because their atomic structure is identical, CVD diamonds share these exact same physical and optical properties. They are just as hard, durable, and brilliant as any natural diamond.

How CVD Diamonds Are Created

The term "lab-grown" can be misleading. The process is not about imitation but about replicating the conditions for diamond growth in a highly controlled and accelerated way.

The Process: Chemical Vapor Deposition (CVD)

The CVD process begins with a tiny, pre-existing diamond slice, often called a "seed." This seed is placed inside a sealed vacuum chamber.

The chamber is heated to a high temperature and filled with a carbon-rich gas, such as methane. At these temperatures, the gas molecules break apart, freeing carbon atoms.

These individual carbon atoms then rain down and deposit onto the diamond seed, building upon its crystal structure layer by layer. Over several weeks, a larger, gem-quality rough diamond grows.

Understanding the Key Differences

While chemically identical, the difference in origin creates practical distinctions that are important for any buyer to understand. The choice is less about "real vs. fake" and more about which set of trade-offs aligns with your priorities.

Origin and Rarity

This is the most significant difference. A natural diamond is a finite geological artifact, billions of years old. A CVD diamond is a product of modern technology that can be produced on demand. This distinction heavily influences perception, marketing, and long-term resale value.

Clarity and Purity

Because they are grown in a sterile, meticulously controlled environment, CVD diamonds often have fewer internal flaws, or inclusions, than many mined diamonds. This can result in stones with exceptionally high clarity and quality for their price point.

Identification

To the naked eye, even for a trained jeweler, there is no visible difference between a high-quality CVD diamond and a natural one.

Distinguishing between them requires advanced gemological laboratory equipment. This specialized equipment can detect subtle differences in the crystal growth patterns and trace elements that are unique to each formation process.

Making the Right Choice for Your Goal

Ultimately, the "better" diamond is the one that best fits your personal values and budget. Both are valid choices, but they serve different priorities.

- If your primary focus is maximizing size and quality for your budget: A CVD diamond is the clear winner, offering a larger and higher-clarity stone for the same cost as a comparable natural diamond.

- If your primary focus is the tradition and romance of a rare, geological treasure: A natural diamond's billion-year-old story and finite nature will hold more appeal.

- If your primary focus is ethical and environmental transparency: A lab-grown diamond provides a clear chain of custody and bypasses the concerns associated with traditional mining operations.

Understanding that CVD diamonds are chemically real empowers you to make a choice based on your own priorities, not on outdated definitions of authenticity.

Summary Table:

| Aspect | CVD Diamond | Mined Diamond |

|---|---|---|

| Chemical Composition | Pure Carbon (C) | Pure Carbon (C) |

| Hardness (Mohs Scale) | 10 | 10 |

| Origin | Lab-Grown (Weeks) | Geological (Billions of Years) |

| Clarity | Often Higher (Fewer Inclusions) | Varies |

| Ethical/Environmental Impact | Lower (Controlled Process) | Higher (Mining Concerns) |

Ready to explore high-quality, ethically sourced diamonds for your needs? KINTEK specializes in precision lab equipment and consumables, including technology for advanced diamond synthesis. Whether you're a jeweler, researcher, or manufacturer, our solutions ensure reliability and efficiency. Contact us today to learn how we can support your laboratory or production goals with cutting-edge tools!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Domes for Industrial and Scientific Applications

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How plasma is used in diamond coating films? Unlock the Power of MPCVD for Superior Coatings

- How are created diamonds made? Discover the Science Behind Lab-Grown Diamonds

- How does a microwave plasma reactor facilitate the synthesis of diamond? Master MPCVD with Precision Technology

- What is the growth rate of CVD diamond? Discover the Secret to High-Purity Lab-Grown Gems

- What is the quality of CVD diamonds? Exceptional Brilliance from a Controlled Lab Process

- How long does it take to synthesize a diamond? The Trade-Off Between Speed and Gem Quality

- Are CVD diamonds synthetic? Discover the Truth About Lab-Grown Diamonds

- What are the defects in CVD diamond? A Guide to Identifying and Assessing Quality