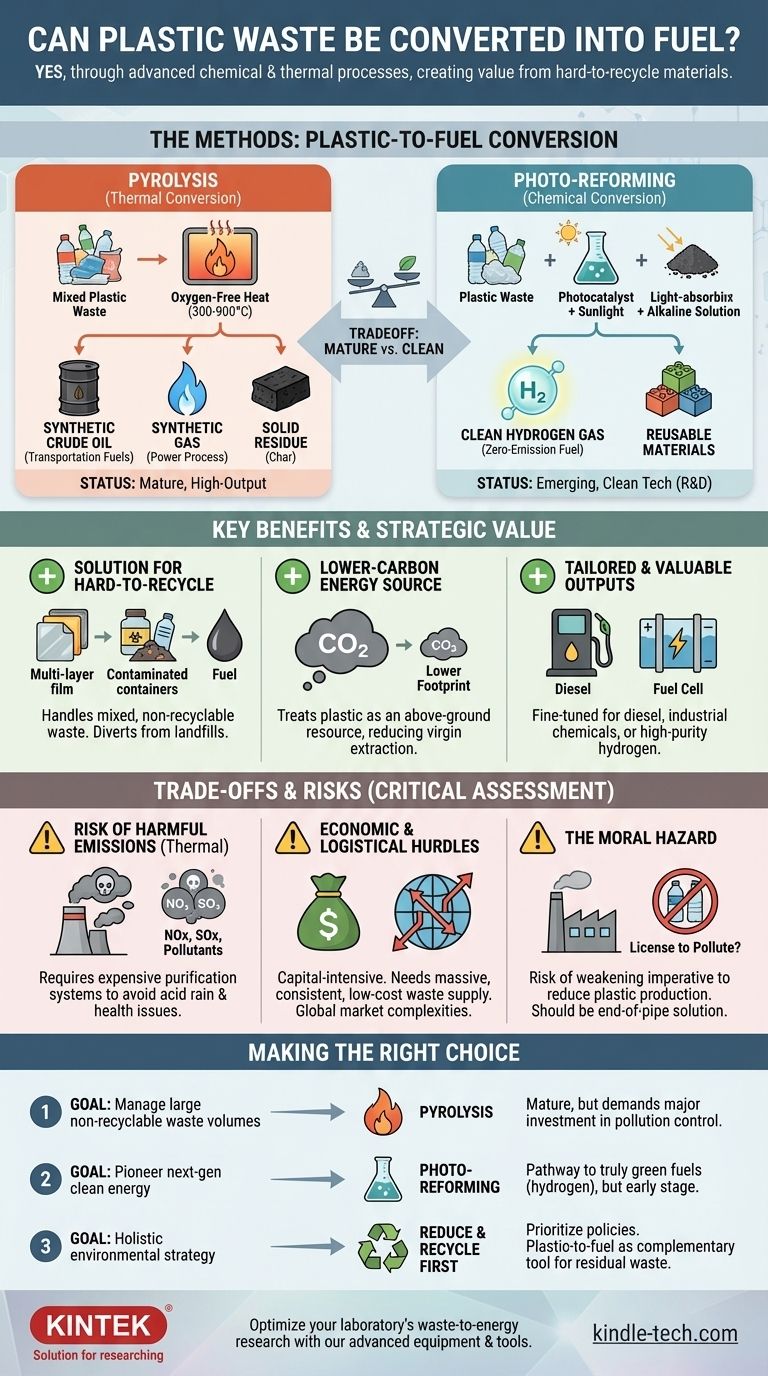

Yes, plastic waste can be converted into fuel through several advanced chemical and thermal processes. Technologies like pyrolysis use high heat to break down plastics into synthetic crude oil, while newer methods like photo-reforming use sunlight to convert plastic waste directly into clean hydrogen gas. These approaches offer a way to create value from hard-to-recycle materials that would otherwise pollute our landfills and oceans.

While converting plastic into fuel is technically feasible and can address non-recyclable waste, its environmental and economic viability is not guaranteed. The specific conversion method used determines the outcome, with a critical trade-off between mature, high-output processes that carry pollution risks and emerging clean technologies that are not yet at scale.

How Plastic is Converted into Fuel

The term "plastic-to-fuel" encompasses several distinct technologies, each with its own process and output. The two most prominent methods are thermal and chemical conversion.

The Dominant Method: Pyrolysis

Pyrolysis is a form of thermal conversion. It involves heating plastic waste to very high temperatures (300-900°C) in an oxygen-free environment.

This intense heat breaks down the long polymer chains of the plastic into smaller, simpler molecules. The primary outputs are a synthetic crude oil (pyrolysis oil), a synthetic gas, and a solid residue called char.

The resulting oil can be refined further into transportation fuels, while the gas can be used to power the pyrolysis process itself, creating a partially self-sustaining system.

The Emerging Method: Photo-reforming

A newer, promising approach involves chemical conversion driven by light. Researchers have developed a process called photo-reforming.

This method involves adding a light-absorbing material (a photocatalyst) to plastic. When submerged in an alkaline solution and exposed to sunlight, the catalyst uses the light's energy to break down the plastic.

Instead of producing a fossil-fuel-like oil, this process generates clean hydrogen gas and leaves behind other reusable materials. It essentially uses sunlight to transform plastic waste into a zero-emission fuel source.

The Key Benefits of Plastic-to-Fuel Technology

When implemented correctly, converting plastic to fuel presents a compelling solution for two of the world's most significant challenges: waste management and energy production.

A Solution for Hard-to-Recycle Plastics

Mechanical recycling has limits. Many plastics, such as multi-layer films, contaminated containers, and certain types of polymers, are difficult or impossible to recycle traditionally.

Plastic-to-fuel processes can handle this mixed, often non-recyclable waste, diverting it from landfills and preventing it from entering the environment.

A Lower-Carbon Energy Source

Compared to extracting, refining, and burning new fossil fuels, using existing plastic waste as a feedstock can result in a lower overall carbon footprint.

It treats plastic as an above-ground resource, reducing the need for virgin petroleum extraction and its associated environmental impact.

Tailored and Valuable Outputs

The conversion processes can be fine-tuned to create specific products. Pyrolysis can be optimized to produce oil suitable for diesel engines or other industrial chemicals.

Emerging methods like photo-reforming create high-purity hydrogen, a critical fuel for clean transportation and green industrial processes.

Understanding the Trade-offs and Risks

Despite its promise, plastic-to-fuel technology is not a perfect solution. The practical and environmental challenges are significant and must be weighed against the benefits.

The Risk of Harmful Emissions

Thermal processes like pyrolysis, if not equipped with sophisticated and expensive gas purification systems, can release harmful pollutants.

These include nitrous oxides (NOx) and sulfur dioxides (SOx), which contribute to acid rain and respiratory problems, as well as other hazardous air pollutants. The claim of being "eco-friendly" is entirely dependent on the quality of the facility's emission controls.

Economic and Logistical Hurdles

Plastic-to-fuel plants are capital-intensive. To be economically viable, they require a massive, consistent, and low-cost supply of plastic waste.

In some regions, this has led to a reliance on importing waste, creating a complex global market for garbage. It can also risk undermining more sustainable economies built around waste reduction and traditional recycling.

The Moral Hazard: A License to Pollute?

The biggest concern is that a focus on plastic-to-fuel could weaken the imperative to reduce plastic production in the first place.

This technology is best viewed as an end-of-pipe solution for existing and unavoidable waste, not an excuse to continue producing single-use plastics under the assumption they can simply be converted to energy.

Making the Right Choice for Your Goal

The decision to invest in or support plastic-to-fuel technology depends entirely on the specific goal you aim to achieve.

- If your primary focus is managing large volumes of non-recyclable municipal waste today: Pyrolysis is the most mature technology available, but it requires major investment in air pollution control systems to be considered a responsible choice.

- If your primary focus is pioneering next-generation clean energy: Photo-reforming and similar chemical conversion methods offer a pathway to truly green fuels like hydrogen, though they are at an earlier stage of technological and commercial readiness.

- If your primary focus is a holistic environmental strategy: Prioritize policies that reduce plastic consumption and improve mechanical recycling first. View plastic-to-fuel as a complementary tool for the residual waste that cannot be eliminated or recycled.

Ultimately, harnessing energy from plastic is a powerful tool in the fight against pollution, but its responsible deployment demands a clear-eyed assessment of both the technology's benefits and its inherent risks.

Summary Table:

| Method | Process | Key Output | Status |

|---|---|---|---|

| Pyrolysis | Thermal decomposition in an oxygen-free environment | Synthetic crude oil, gas, char | Mature, commercially deployed |

| Photo-reforming | Chemical breakdown using sunlight and a catalyst | Hydrogen gas, reusable materials | Emerging, in R&D phase |

Optimize your laboratory's waste-to-energy research with KINTEK.

As a leading supplier of advanced lab equipment and consumables, KINTEK provides the tools you need to explore and scale up plastic-to-fuel conversion processes—from pyrolysis reactors to analytical instruments for monitoring outputs. Whether you're developing next-generation catalysts or validating emission controls, our solutions help you achieve accurate, reliable results.

Contact us today to discuss how we can support your specific research goals and contribute to a more sustainable future.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 1700℃ Muffle Oven Furnace for Laboratory

- CVD Diamond for Thermal Management Applications

- High Performance Laboratory Freeze Dryer

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition