Yes, titanium can be sintered. This manufacturing process, a cornerstone of powder metallurgy, involves compacting titanium powder into a desired shape and then heating it in a controlled environment. This fuses the particles together below the metal's melting point, forming a solid, functional component.

Sintering titanium is not just possible; it is a key manufacturing strategy for creating complex, cost-effective parts with minimal material waste. The success of the process, however, hinges on carefully managing titanium's high reactivity, especially with oxygen.

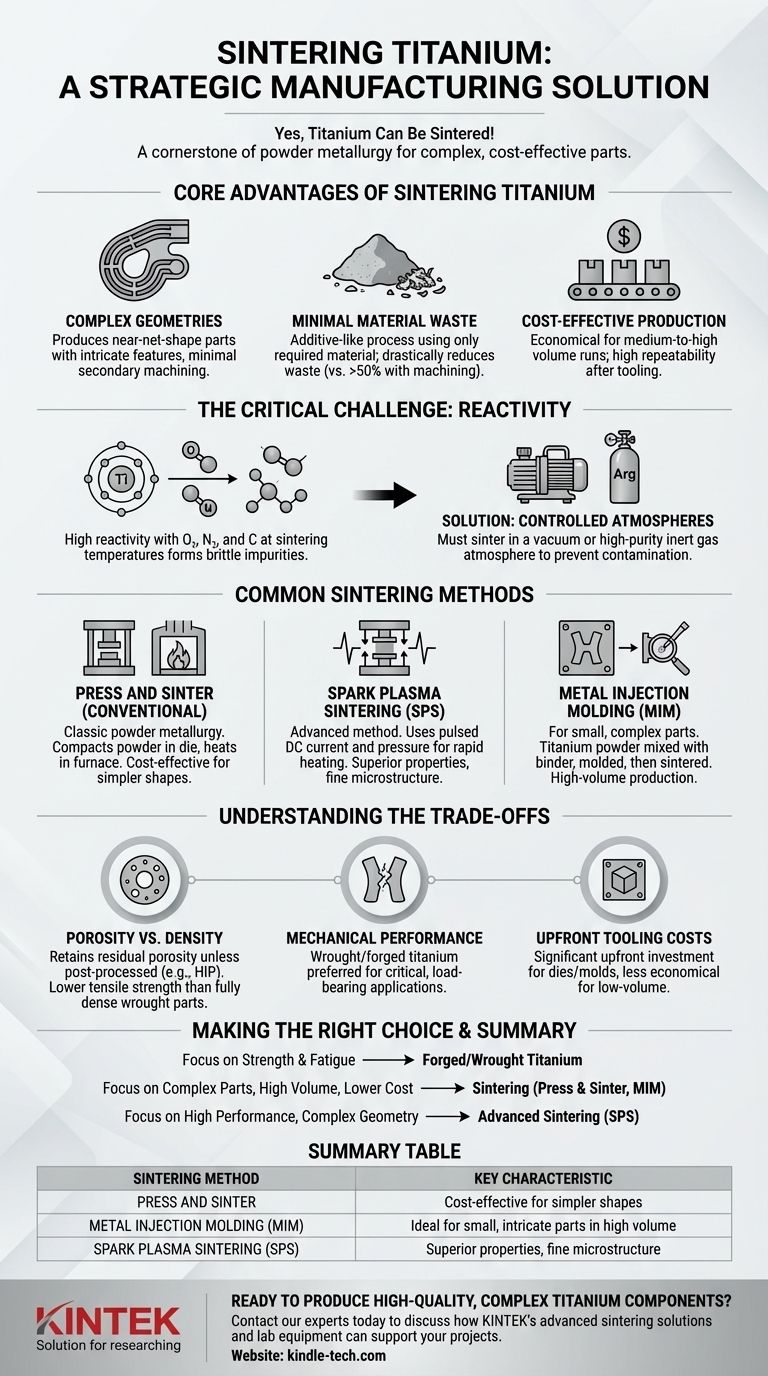

Why Sinter Titanium? The Core Advantages

While titanium is famous for its strength and light weight, it is also notoriously difficult and expensive to machine. Sintering provides a powerful alternative for many applications.

Creating Complex Geometries

Sintering excels at producing near-net-shape parts. This means the component comes out of the furnace very close to its final dimensions, requiring minimal secondary processing.

This method allows for intricate features like internal channels or complex curves that would be extremely costly or impossible to create with traditional subtractive machining.

Minimizing Material Waste

Machining a part from a solid block of titanium can waste over 50% of the expensive raw material, which is lost as chips.

Sintering is an additive-like process that uses only the material needed for the part itself. This drastic reduction in waste is a significant driver of its cost-effectiveness.

Achieving Cost-Effective Production

For medium-to-high volume production runs, sintering is significantly more economical than machining each part individually.

Once the initial tooling (like a press die or an injection mold) is created, parts can be produced rapidly and with high repeatability, lowering the per-unit cost.

The Critical Challenge: Managing Titanium's Reactivity

The primary obstacle in sintering titanium is its aggressive tendency to react with atmospheric elements at high temperatures.

The Problem with Contamination

At sintering temperatures, titanium readily absorbs oxygen, nitrogen, and carbon from the air. This contamination forms brittle compounds within the metal's structure.

Even small amounts of these impurities can dramatically reduce the ductility and fatigue life of the final part, rendering it useless for any demanding application.

The Solution: Controlled Atmospheres

To prevent contamination, titanium must be sintered in a vacuum or in a high-purity inert gas atmosphere, such as argon.

This controlled environment starves the process of the reactive elements, preserving the inherent chemical purity and mechanical properties of the titanium.

Common Sintering Methods for Titanium

Different sintering techniques offer distinct advantages in cost, complexity, and final part performance.

Conventional Sintering (Press and Sinter)

This is the classic powder metallurgy route. Titanium powder is compacted into a "green" part using a die press and then heated in a furnace. It is a cost-effective method for simpler shapes.

Spark Plasma Sintering (SPS)

SPS is an advanced method that uses a combination of high pressure and a pulsed DC electrical current to heat the powder rapidly.

This speed inhibits grain growth and allows for full densification at lower temperatures, resulting in superior mechanical properties. It is often used for high-performance biomaterials and aerospace components.

Metal Injection Molding (MIM)

For highly complex, small-to-medium-sized parts, MIM is an excellent option. Fine titanium powder is mixed with a polymer binder to create a feedstock that can be injection molded like plastic. The binder is then removed, and the part is sintered.

Understanding the Trade-offs

While powerful, sintering is not a universal solution. It is crucial to understand its inherent limitations compared to traditional manufacturing.

Porosity vs. Density

Unless advanced techniques like Hot Isostatic Pressing (HIP) are used as a secondary step, most sintered parts retain a small amount of residual porosity.

This means they are not 100% dense. This porosity can be an initiation point for cracks, potentially reducing the ultimate tensile strength and fatigue life compared to a fully dense wrought or forged part.

Mechanical Performance

For the most critical, load-bearing applications (like a landing gear component), a forged and machined part will almost always offer superior and more predictable performance due to its complete density and optimized grain structure.

Upfront Tooling Costs

The press dies and injection molds required for sintering represent a significant upfront investment. This makes the process less economical for prototypes or very small production runs.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process depends entirely on the specific requirements of your component.

- If your primary focus is maximum strength and fatigue life: Forged or wrought titanium, machined to its final shape, remains the gold standard.

- If your primary focus is producing complex parts in high volume at a lower cost: Sintering via Press and Sinter or Metal Injection Molding (MIM) is the superior choice.

- If your primary focus is high performance with complex geometry and a fine microstructure: Advanced methods like Spark Plasma Sintering (SPS) offer a powerful balance of properties.

By understanding the fundamental trade-off between manufacturing complexity and material density, you can confidently select the right process for your titanium component.

Summary Table:

| Aspect | Sintering Method | Key Characteristic |

|---|---|---|

| Cost & Simplicity | Press and Sinter | Cost-effective for simpler shapes |

| Complexity & Volume | Metal Injection Molding (MIM) | Ideal for small, intricate parts in high volume |

| Performance & Density | Spark Plasma Sintering (SPS) | Superior properties, fine microstructure |

Ready to produce high-quality, complex titanium components?

KINTEK specializes in advanced sintering solutions and the lab equipment needed for success. Our expertise in controlled atmosphere furnaces and powder metallurgy can help you achieve cost-effective production of intricate titanium parts with minimal material waste.

Contact our experts today to discuss how we can support your titanium sintering projects and enhance your laboratory's capabilities.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the difference between furnace brazing and induction brazing? Choose the Right Process for Your Project

- What is the purpose of a laboratory vacuum drying oven in catalyst post-processing? Preserve Activity & Pore Structure

- What is the difference between plasma nitriding and nitriding? Unlock Superior Surface Hardening Control

- Why is a laboratory vacuum oven necessary for LIPS preparation? Unlock ZIF-8 Pore Activation & Lubricant Infusion

- What is the difference between vertical and horizontal furnace semiconductors? Unlock Superior Yield and Uniformity

- What is the role of a vacuum drying oven in PEO-based membrane treatment? Achieve Peak Solid-State Battery Purity

- What are the two types of furnace technologies used in heat treatment? Atmosphere vs. Vacuum Explained

- What is the vacuum level of a vacuum furnace? Match the Right Vacuum to Your Process