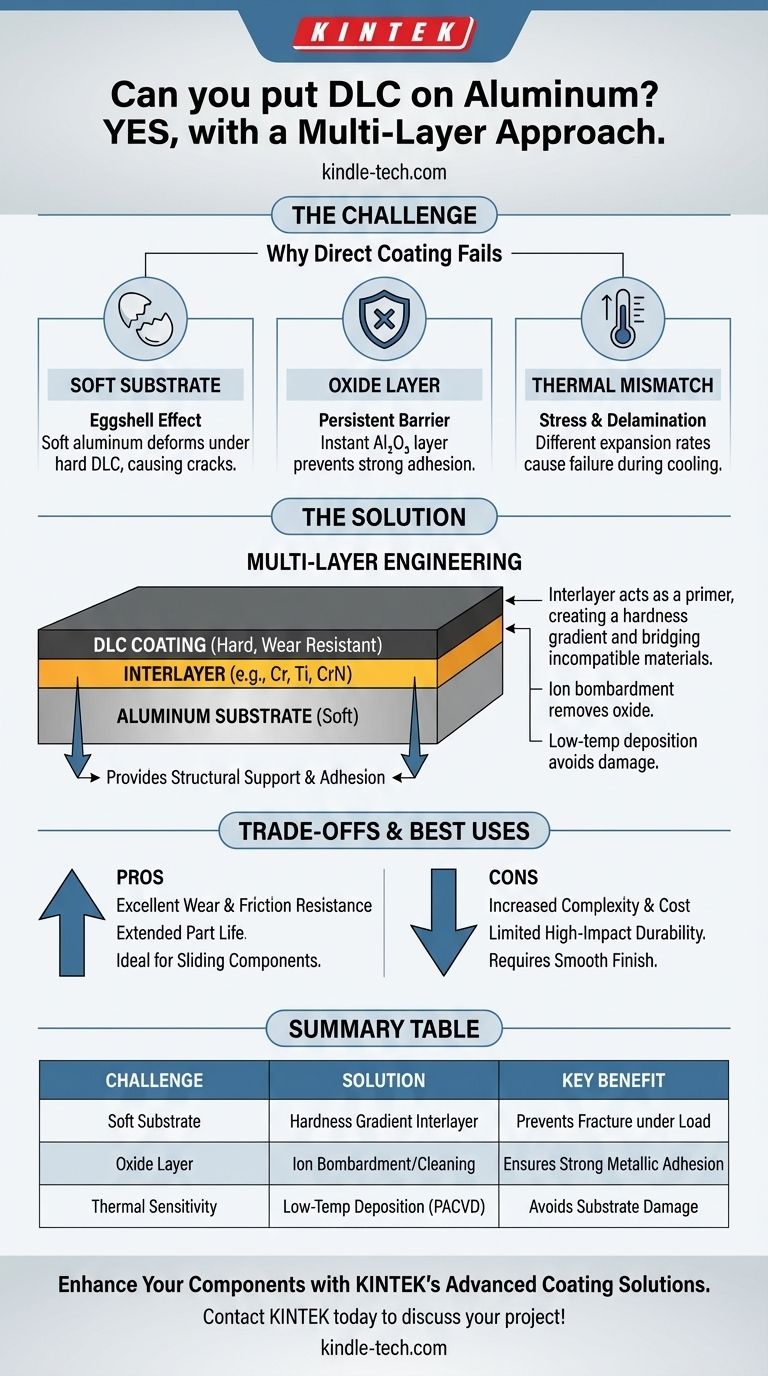

Yes, you can absolutely coat aluminum with Diamond-Like Carbon (DLC). However, it is not a direct process. Successfully applying DLC to an aluminum substrate requires a specialized approach involving carefully selected intermediate layers to overcome the inherent challenges posed by aluminum's soft nature and its persistent, non-adherent oxide layer.

The critical takeaway is that a direct DLC coating on aluminum will fail. Success hinges on using a multi-layer system, where an initial "primer" layer like chromium or titanium is first applied to the aluminum to ensure adhesion and provide a stable foundation for the final DLC topcoat.

Why Coating Aluminum with DLC is a Challenge

Understanding the difficulties involved is key to appreciating the solution. Aluminum presents three primary obstacles for hard coatings like DLC.

The Soft Substrate Problem (The "Eggshell Effect")

Aluminum alloys are significantly softer than the very hard, thin DLC film. Applying a hard coating directly to a soft base creates a scenario known as the "eggshell effect."

Imagine placing a thin sheet of glass on a foam mattress. The glass is hard, but any focused pressure will cause the foam to deform, offering no support and allowing the glass to crack easily. A DLC film on raw aluminum behaves in the same way.

The Persistent Oxide Layer

Aluminum instantaneously forms a tough, chemically inert layer of aluminum oxide (Al₂O₃) upon exposure to air. This microscopic layer is excellent for corrosion resistance but terrible for coating adhesion.

Most physical vapor deposition (PVD) processes used for DLC require a perfectly clean, metallic surface to form a strong bond. The native oxide layer acts as a barrier, preventing the coating from properly adhering to the base metal.

Thermal Sensitivity and Mismatch

The processes used to deposit DLC can involve elevated temperatures. Aluminum has a relatively low melting point and a high coefficient of thermal expansion compared to the ceramic-like DLC.

This mismatch can induce stress between the coating and the substrate as they cool, leading to poor adhesion, cracking, or even delamination of the coating.

The Solution: A Multi-Layer Engineering Approach

Specialized coating providers overcome these challenges not with a single layer, but with an engineered system of multiple layers.

The Critical Role of an Interlayer

The most crucial step is the deposition of one or more intermediate layers, often called bond layers or interlayers. These materials are chosen because they adhere well to both the aluminum substrate and the subsequent DLC film.

Common interlayer materials include chromium (Cr), titanium (Ti), and chromium nitride (CrN). This layer acts as a "primer," creating a strong bridge between the two otherwise incompatible materials.

Providing Structural Support

A well-chosen interlayer system doesn't just improve adhesion; it also helps mitigate the eggshell effect. By using a material that is harder than aluminum but softer than DLC, it creates a hardness gradient.

This gradual transition from the soft substrate to the hard coating provides the necessary support to keep the DLC film from fracturing under load.

Advanced Surface Preparation

Before any coating begins, the aluminum part is placed in a vacuum chamber. Inside the chamber, a process called ion bombardment or sputter cleaning is used.

This is essentially a micro-sandblasting process using plasma to strip away the native oxide layer, exposing a pristine, metallic aluminum surface right before the interlayer is applied.

Low-Temperature Deposition

To avoid heat-related problems, a low-temperature deposition process is used. Techniques like Plasma-Assisted Chemical Vapor Deposition (PACVD) can deposit high-quality DLC coatings at temperatures below 200°C (392°F), well within the safe working range for most aluminum alloys.

Understanding the Trade-offs

While effective, this advanced process has implications you must consider.

Increased Complexity and Cost

A multi-layer DLC coating on aluminum is a more complex and technically demanding process than coating a simple steel part. This translates to higher costs and requires a provider with specific expertise in coating light metals.

Limited Impact Resistance

Even with a supportive interlayer, the system's overall toughness is ultimately limited by the softness of the base aluminum. The coating provides exceptional wear and friction resistance, but it will not make an aluminum part withstand heavy, sharp impacts like a coated tool steel part would.

Importance of Surface Finish

DLC coatings are extremely thin, typically only 1 to 5 microns. They will replicate the underlying surface texture of the part, not hide it. A smooth, well-prepared initial surface finish is essential for a high-quality final result.

Making the Right Choice for Your Application

Deciding if DLC is the right solution depends entirely on your goal for the aluminum component.

- If your primary focus is reducing friction and light abrasive wear: For applications like pistons, sliding components, or robotics parts, a properly applied DLC coating is an excellent and highly effective solution.

- If your primary focus is high-impact durability: For applications where the part will be subject to sharp impacts, DLC will help but won't solve the core issue of aluminum's softness. You may need to consider hard anodizing or a different base material entirely.

- If your primary focus is corrosion resistance in a saline environment: While DLC is very inert, any microscopic pinhole in the coating could lead to galvanic corrosion. Hard anodizing is often a more reliable choice for pure corrosion protection.

By understanding the necessity of a multi-layer system, you can successfully leverage the exceptional properties of DLC to enhance your aluminum components for demanding applications.

Summary Table:

| Challenge | Solution | Key Benefit |

|---|---|---|

| Soft Substrate (Eggshell Effect) | Hardness Gradient Interlayer (e.g., Cr, Ti) | Prevents coating fracture under load |

| Persistent Oxide Layer | Ion Bombardment / Sputter Cleaning | Ensures strong metallic adhesion |

| Thermal Sensitivity | Low-Temperature Deposition (e.g., PACVD) | Avoids substrate damage |

Enhance your aluminum components with high-performance DLC coatings from KINTEK! Our specialized multi-layer processes are engineered to overcome aluminum's unique challenges, providing superior wear resistance, reduced friction, and extended part life for your laboratory equipment and precision components.

Let our experts help you select the right coating solution for your specific application. Contact KINTEK today to discuss your project needs and discover how our advanced lab equipment and consumables can optimize your results.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Domes for Industrial and Scientific Applications

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the disadvantages of plasma enhanced chemical vapor deposition? Managing the Trade-offs of Low-Temperature Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition