In short, no. PVD-coated stainless steel does not tarnish. The PVD (Physical Vapor Deposition) process applies a thin, ceramic-based coating that is chemically inert and forms a protective barrier over the non-tarnishing stainless steel base. This combination is highly resistant to the chemical reactions, like oxidation, that cause traditional tarnishing.

The question of whether PVD tarnishes misunderstands its core nature. PVD is not a metal that can react with the air; it is a microscopic, protective ceramic shield. The true measure of its longevity is not its resistance to tarnish (which is absolute), but its exceptional durability against physical wear and scratches.

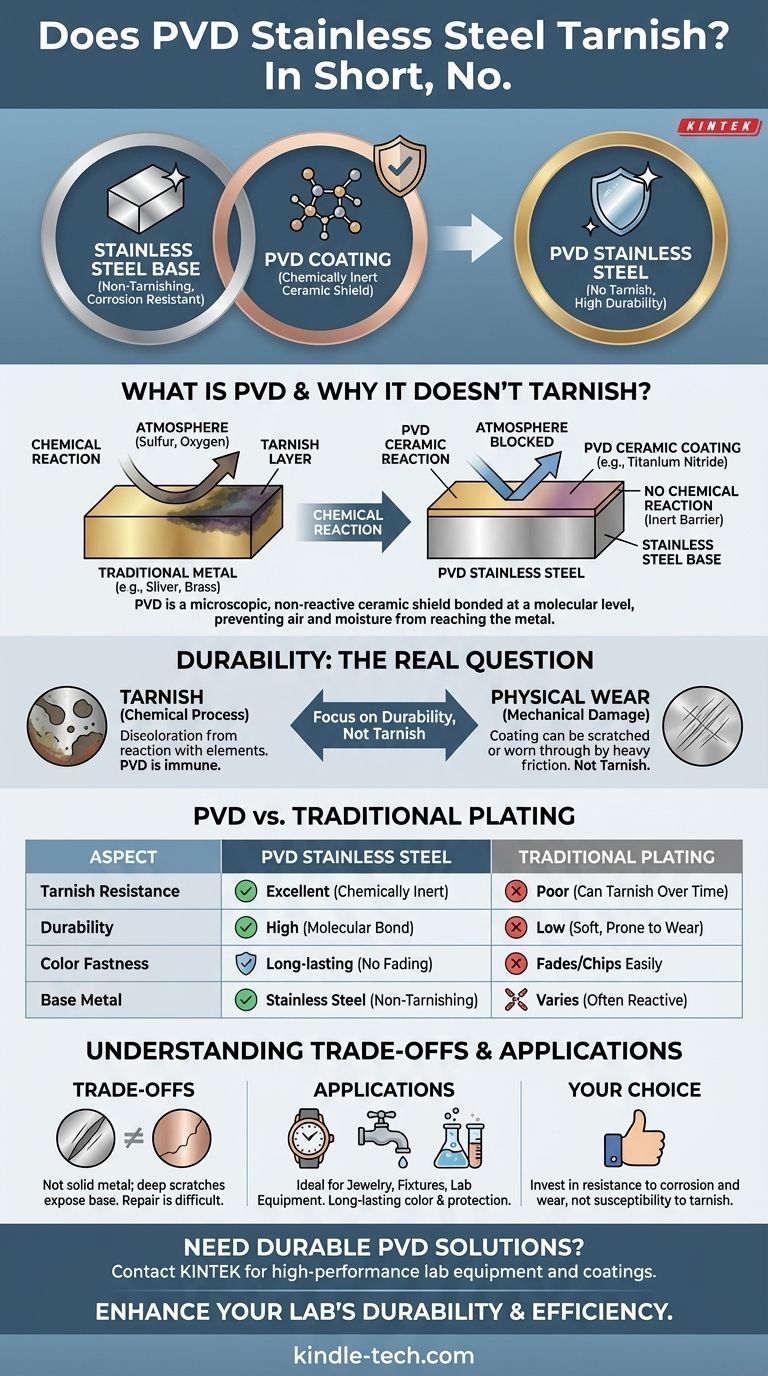

What is PVD and Why Doesn't It Tarnish?

To understand why PVD finishes are so robust, we need to distinguish between the coating, the base metal, and the process of tarnishing itself.

Demystifying "Tarnish"

Tarnish is a chemical process. It's a mild form of corrosion that occurs when a metal's surface reacts with elements in the atmosphere, primarily sulfur, causing a dark, discolored layer to form. This is most common with silver and copper-based alloys like brass.

The Role of Stainless Steel

Stainless steel, the base metal in this case, is already highly resistant to rust and tarnish. Its chromium content (typically over 10.5%) creates a passive, self-repairing oxide layer that protects the iron within from corrosion.

The PVD Coating: A Protective Shield

Physical Vapor Deposition is a vacuum coating process that bonds a microscopic layer of ceramic material (like titanium nitride or zirconium nitride) to the stainless steel surface. This coating is what gives the steel its color—gold, black, rose gold, etc.

Because this ceramic layer is non-reactive and extremely dense, it creates an impenetrable barrier. It completely prevents air and moisture from ever reaching the metal surface, making chemical reactions like tarnishing impossible.

Durability: The Real Question Behind "Tarnish"

When people ask about tarnishing, their underlying concern is usually about color fastness and longevity. Will the color fade, chip, or wear off? This is where PVD truly outperforms other coloring methods.

PVD vs. Traditional Plating

Traditional electroplating deposits a thin layer of metal (like gold) onto a base. This layer is relatively soft and adheres through a weaker electro-chemical bond, making it prone to chipping, flaking, and wearing away.

PVD, by contrast, is bonded to the stainless steel at a molecular level. The resulting finish is not just a layer on the steel; it's integrated with the steel's surface, making it significantly harder and more durable.

Understanding Wear and Tear

The color of a PVD finish will not fade. However, the coating itself can be physically removed. It has extremely high resistance to abrasion, but it is not indestructible.

Consistent, heavy friction or a deep scratch from a sharp object can eventually wear through the thin ceramic coating. If this happens, it will reveal the silver-colored stainless steel underneath. This is mechanical wear, not a chemical change like tarnishing.

Understanding the Trade-offs

While PVD is a superior technology, it's crucial to understand its limitations to set realistic expectations.

It's a Coating, Not Solid Metal

The primary limitation is that the color comes from a coating. Unlike solid gold, where a scratch simply reveals more gold, a deep scratch on a PVD product will expose the underlying base metal. This damage cannot be "polished out."

Repair is Not Practical

Re-applying a PVD coating requires specialized industrial equipment. For a single consumer item like a watch or a ring, refinishing a damaged PVD surface is typically not a feasible or cost-effective option. The damage is, for all practical purposes, permanent.

Quality Varies

The durability of a PVD finish depends on the quality of the application, including its thickness and the specific materials used. Reputable manufacturers produce highly durable finishes, but not all PVD applications are created equal.

Making the Right Choice for Your Application

PVD on stainless steel offers a premium, long-lasting finish for a wide range of products. Here is how to apply this knowledge.

- If your primary focus is daily-wear jewelry or watches: PVD stainless steel is an excellent, durable, and often hypoallergenic choice that will hold its color far longer than plated alternatives.

- If your primary focus is kitchen or bath fixtures: PVD is a superior choice, offering a finish that resists water spots, cleaning chemicals, and corrosion, often lasting for decades with basic care.

- If your primary focus is avoiding color change: PVD is the definitive solution, as the ceramic coating is inert and will not tarnish or react to environmental factors.

By choosing PVD stainless steel, you are investing in a finish defined by its exceptional resistance to corrosion and wear, not its susceptibility to tarnish.

Summary Table:

| Aspect | PVD Stainless Steel | Traditional Plating |

|---|---|---|

| Tarnish Resistance | Excellent (Chemically inert) | Poor (Can tarnish over time) |

| Durability | High (Molecular bond) | Low (Soft, prone to wear) |

| Color Fastness | Long-lasting (No fading) | Fades/chips easily |

| Base Metal | Stainless steel (Non-tarnishing) | Varies (Often reactive) |

Need a PVD coating that stands the test of time? At KINTEK, we specialize in high-performance lab equipment and consumables, including durable PVD solutions tailored for demanding environments. Our coatings ensure lasting color and protection for your precision instruments. Contact our experts today to enhance your lab's durability and efficiency!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How do CVD diamonds grow? A Step-by-Step Guide to Lab-Grown Diamond Creation

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- Is sputtering a PVD? Discover the Key Coating Technology for Your Lab

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What is direct current DC magnetron sputtering? A Guide to High-Quality Thin Film Deposition