The accuracy of a test sieve is not a single measurement but is strictly defined by its compliance with manufacturing standards like ASTM E11 or ISO 3310-1. These standards dictate the precise, permissible variations in the sieve's wire mesh openings. A sieve is considered "accurate" if its apertures fall within the tight tolerances set by these universally accepted guidelines.

The concept of "accuracy" in a test sieve refers to its conformity to a specific industrial standard. This ensures that particle size analysis results are repeatable, reliable, and comparable across different tests and laboratories.

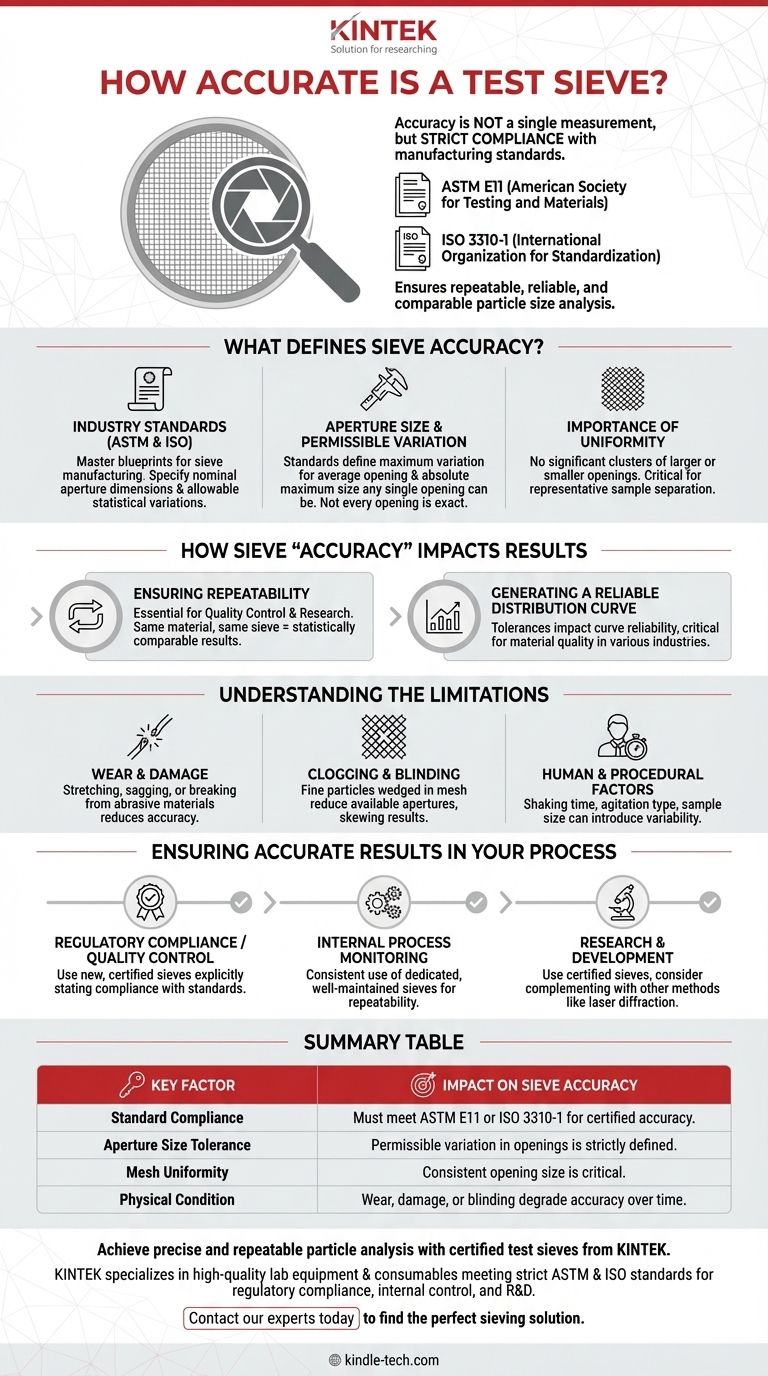

What Defines Sieve Accuracy?

The reliability of a sieve analysis hinges entirely on the physical characteristics of the sieve itself. These characteristics are not left to chance; they are rigorously defined by international standards bodies to ensure consistency across industries.

The Role of Industry Standards (ASTM & ISO)

The bedrock of sieve accuracy is adherence to standards like ASTM E11 (American Society for Testing and Materials) and ISO 3310 (International Organization for Standardization). These documents provide the master blueprint for sieve manufacturing.

They specify the nominal dimensions of the apertures (the holes) and, more importantly, the allowable statistical variations for those openings. A sieve cannot be considered an accurate scientific instrument without certification to one of these standards.

Aperture Size and Permissible Variation

A sieve labeled "1 mm" does not mean every single opening is exactly 1.000 mm. The standard allows for a very small range of sizes.

The standard defines the maximum variation for an average opening as well as the absolute maximum size any single opening can be. This ensures that, on the whole, the sieve performs its separation function within a predictable and repeatable tolerance.

The Importance of Uniformity

Accuracy also depends on the uniformity of the wire mesh across the entire surface of the sieve. A high-quality, certified test sieve will not have significant clusters of larger or smaller openings in any one area. This uniformity is critical for obtaining a representative sample separation.

How Sieve "Accuracy" Impacts Your Results

Using a properly specified and certified sieve is the difference between generating random data and producing reliable, actionable information. The quality of the tool directly dictates the quality of the outcome.

Ensuring Repeatability

For quality control and scientific research, repeatability is essential. An accurate sieve ensures that if you test the same material again tomorrow, or in a different facility with the same sieve stack, you will get statistically comparable results.

Generating a Reliable Distribution Curve

The ultimate goal of stacking sieves in a shaker is to generate a particle size distribution curve. The defined tolerances of each sieve in the stack directly impact the reliability of this curve, which is often a critical quality parameter for materials in industries from pharmaceuticals to construction.

Understanding the Limitations

While a certified sieve is an accurate tool, its effectiveness can be compromised by physical wear and procedural errors. Understanding these factors is key to maintaining data integrity.

Wear and Damage

Over time, the wire mesh on a sieve can stretch, sag, or break from use. Abrasive materials can wear down the wires, subtly enlarging the apertures. This physical degradation directly reduces the sieve's accuracy.

Clogging and Blinding

Fine particles can become wedged in the mesh openings, a phenomenon known as blinding. This effectively reduces the number of available apertures, slows down the sieving process, and can skew results by preventing properly sized particles from passing through.

The Human and Procedural Factor

The most accurate sieve in the world can produce poor data if the procedure is flawed. Factors like the amount of time spent shaking, the type of agitation used, and the size of the initial sample can all introduce variability that has nothing to do with the sieve itself.

Ensuring Accurate Results in Your Process

Choosing and maintaining your equipment correctly is fundamental to achieving reliable particle analysis. Your specific goal will determine the level of precision required.

- If your primary focus is regulatory compliance or certified quality control: You must use new, certified sieves that explicitly state their compliance with ASTM E11 or the relevant ISO standard for your industry.

- If your primary focus is internal process monitoring: Consistent use of a dedicated set of well-maintained sieves can provide the necessary repeatability, but be aware that results may not be directly comparable to other labs without official certification.

- If your primary focus is research and development: Use certified sieves and consider complementing your analysis with other methods, like laser diffraction, for a more comprehensive understanding of particle characteristics.

Ultimately, a test sieve's accuracy is a function of its manufacturing precision, which provides the foundation for repeatable and trustworthy particle analysis.

Summary Table:

| Key Factor | Impact on Sieve Accuracy |

|---|---|

| Standard Compliance | Must meet ASTM E11 or ISO 3310-1 for certified accuracy. |

| Aperture Size Tolerance | Permissible variation in wire mesh openings is strictly defined. |

| Mesh Uniformity | Consistent opening size across the entire sieve surface is critical. |

| Physical Condition | Wear, damage, or blinding from use can degrade accuracy over time. |

Achieve precise and repeatable particle analysis with certified test sieves from KINTEK.

KINTEK specializes in high-quality lab equipment and consumables, providing test sieves that meet rigorous ASTM and ISO standards. Whether your focus is on strict regulatory compliance, internal process control, or R&D, our sieves deliver the accuracy and reliability your laboratory demands.

Ensure your results are trustworthy and comparable. Contact our experts today to find the perfect sieving solution for your specific application.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Small Lab Rubber Calendering Machine

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

People Also Ask

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- What are the advantages of the sieve method? Achieve Fast, Reliable Particle Size Analysis

- What are the practical applications of sieve analysis? Ensure Material Quality from Construction to Food

- What is the effective size of a sieve? Understand D10 for Soil Permeability & Stability

- What are the ASTM standard sieves? Ensure Accurate Particle Size Analysis with Precision Sieves

- What are the pros and cons of sieve analysis? A Practical Guide to Particle Size Distribution

- What is using a sieve to separate a solid from a liquid? A Simple Guide to Mechanical Separation

- What role do standard sieves play in the research of graphite flake protection? Quantifying Flake Recovery Rates