In short, carbon nanotubes (CNTs) are characterized using a suite of advanced analytical techniques, primarily electron microscopy to determine physical structure and spectroscopy to assess quality and chemical properties. These methods are essential for verifying that the CNTs produced meet the precise specifications required for their intended application, whether in batteries, composites, or electronics.

Characterizing carbon nanotubes is not about a single measurement. It is a systematic process of using multiple complementary techniques to build a complete picture of their structural integrity, purity, and surface chemistry—the key factors that directly govern their performance.

Why Characterization Is a Critical Step

The synthesis process, whether chemical vapor deposition (CVD), laser ablation, or arc discharge, rarely produces a perfectly uniform product. The output is often a mix of CNTs with different lengths, diameters, and numbers of walls, alongside impurities like amorphous carbon and leftover metal catalysts.

Characterization is the quality control gate. It ensures that the batch of CNTs has the specific properties—such as high aspect ratio, purity, or surface functionalization—that are required for high-performance applications like conductive polymers or advanced battery electrodes.

Core Characterization Techniques and What They Reveal

A comprehensive analysis relies on combining several techniques, as each provides a unique piece of the puzzle.

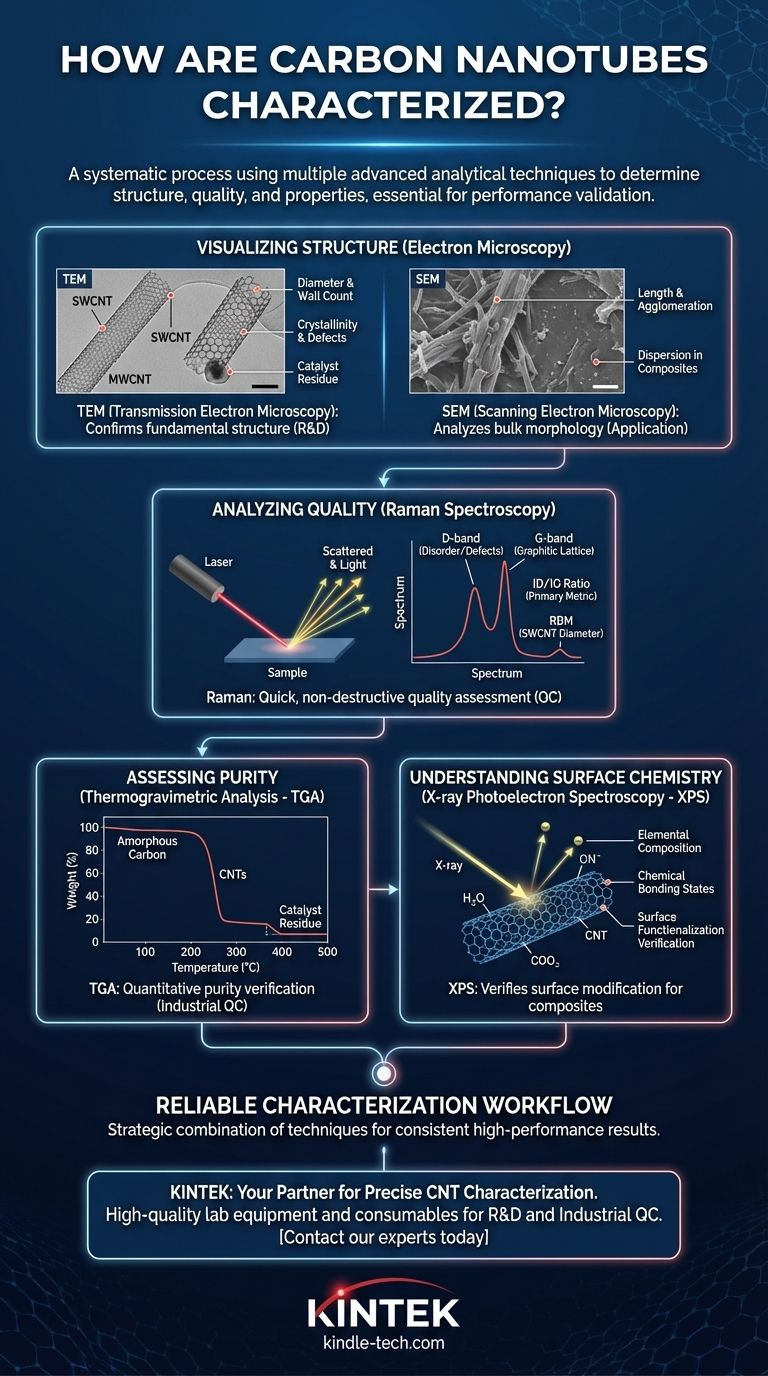

Visualizing Structure: Electron Microscopy (TEM & SEM)

Transmission Electron Microscopy (TEM) is the gold standard for observing the fundamental structure of individual nanotubes. By passing an electron beam through an ultra-thin sample, TEM provides direct visual evidence of:

- Diameter and Wall Count: Clearly distinguishing between single-wall (SWCNT), double-wall (DWCNT), and multi-wall (MWCNT) nanotubes.

- Crystallinity and Defects: Revealing breaks, bends, or imperfections in the graphitic lattice of the nanotube walls.

- Catalyst Residue: Identifying the location and nature of metallic impurities, often encapsulated within the tubes.

Scanning Electron Microscopy (SEM) is used to analyze the bulk morphology of the CNT powder or film. It offers a wider field of view to assess:

- Length and Agglomeration: Determining the average length and aspect ratio of the nanotubes and, crucially, how they bundle together.

- Dispersion: In a composite material, SEM can show how well the CNTs have been distributed within the host matrix.

Analyzing Quality: Raman Spectroscopy

Raman spectroscopy is arguably the most powerful non-destructive technique for quickly assessing CNT quality. It involves shining a laser on the sample and analyzing the scattered light, which reveals the vibrational modes of the carbon atoms. Key features in the Raman spectrum include:

- The D-band: Its intensity indicates the level of disorder and defects in the carbon structure. A smaller D-band is generally better.

- The G-band: This peak corresponds to the ideal graphitic lattice. The ratio of the D-band to the G-band (ID/IG) is a primary metric for CNT quality.

- Radial Breathing Modes (RBMs): Present only for SWCNTs, these low-frequency peaks are directly related to the nanotube's diameter.

Assessing Purity: Thermogravimetric Analysis (TGA)

TGA measures the change in a sample's mass as it is heated. This is the most common method for quantifying purity.

As the temperature rises, different components burn off at distinct temperatures. A typical TGA curve for CNTs shows a first weight loss from amorphous carbon and a second, higher-temperature loss from the nanotubes themselves. Any remaining mass at the end is attributed to non-combustible metal catalyst residue.

Understanding Surface Chemistry: X-ray Photoelectron Spectroscopy (XPS)

XPS is a surface-sensitive technique used to determine the elemental composition and chemical bonding states on the surface of the nanotubes.

This is especially critical when CNTs have been intentionally modified or "functionalized" to improve their bonding with a polymer or their solubility in a solvent. XPS confirms that the desired chemical groups have been successfully attached to the CNT surface.

Understanding the Trade-offs: Local vs. Bulk Analysis

A common challenge in CNT characterization is the difference between what you see in a microscope and the properties of the entire batch.

The Microscopy Dilemma

Techniques like TEM provide incredibly detailed information about a very small number of nanotubes. While you can confirm a perfect structure for one tube, it may not be representative of the trillions of others in the gram of powder you are using.

The Bulk Measurement Advantage

In contrast, techniques like TGA and Raman spectroscopy analyze a much larger, more representative sample. However, they provide an averaged result. A good Raman spectrum might hide the presence of a few very poor-quality tubes, just as a good TGA result might mask localized clumps of catalyst.

The Multi-Technique Solution

Because of these trade-offs, a single technique is never sufficient. Trustworthy characterization relies on a combination of methods: using microscopy to confirm the fundamental structure and bulk techniques to ensure the overall batch meets purity and quality standards.

Matching Characterization to Your Goal

The required level of characterization depends entirely on your objective.

- If your primary focus is fundamental R&D: You need high-resolution TEM to understand the atomic structure and detailed Raman analysis to correlate synthesis parameters with nanotube quality.

- If your primary focus is industrial quality control: TGA for quantitative purity and routine Raman scans for consistency (the ID/IG ratio) are your most efficient and critical tools.

- If your primary focus is application development (e.g., composites): SEM to analyze dispersion within the matrix and XPS to verify surface functionalization are paramount, alongside bulk property measurements.

Ultimately, a strategic characterization plan is the key to transforming carbon nanotubes from a promising raw material into a reliable, high-performance component.

Summary Table:

| Technique | Key Information Revealed | Primary Use Case |

|---|---|---|

| TEM (Microscopy) | Diameter, wall count, crystallinity, defects | Confirming fundamental structure (R&D) |

| SEM (Microscopy) | Length, agglomeration, dispersion in composites | Analyzing bulk morphology & application integration |

| Raman Spectroscopy | Quality (D/G band ratio), defects, SWCNT diameter | Quick, non-destructive quality assessment (QC) |

| TGA (Thermal) | Quantitative purity (amorphous carbon, catalyst residue) | Batch purity verification (Industrial QC) |

| XPS (Surface) | Surface elemental composition, chemical functionalization | Verifying surface modification for composites |

Need to ensure your carbon nanotubes meet exact specifications for your research or product development?

KINTEK specializes in providing the high-quality lab equipment and consumables essential for precise CNT characterization. Whether your focus is on fundamental R&D requiring high-resolution TEM analysis or industrial quality control relying on efficient TGA and Raman systems, we have the solutions to support your work.

Let us help you build a reliable characterization workflow. Contact our experts today to discuss your specific application needs and how our products can help you achieve consistent, high-performance results.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Automatic Laboratory Heat Press Machine

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What are the four main types of sensors? A Guide to Power Source and Signal Type

- How are PTFE gaskets utilized for POEGMA electrolyte conductivity? Ensure Precision in Electrochemical Measurements

- What is the difference between PPF and coating? Armor vs. Slick Shell for Your Car

- What are the specific applications of PTFE in micro-batch slug flow systems? Enhance Your Microfluidic Reaction Purity

- Why are PTFE laboratory consumables required when testing stainless steel against organic acids? Ensure Data Integrity