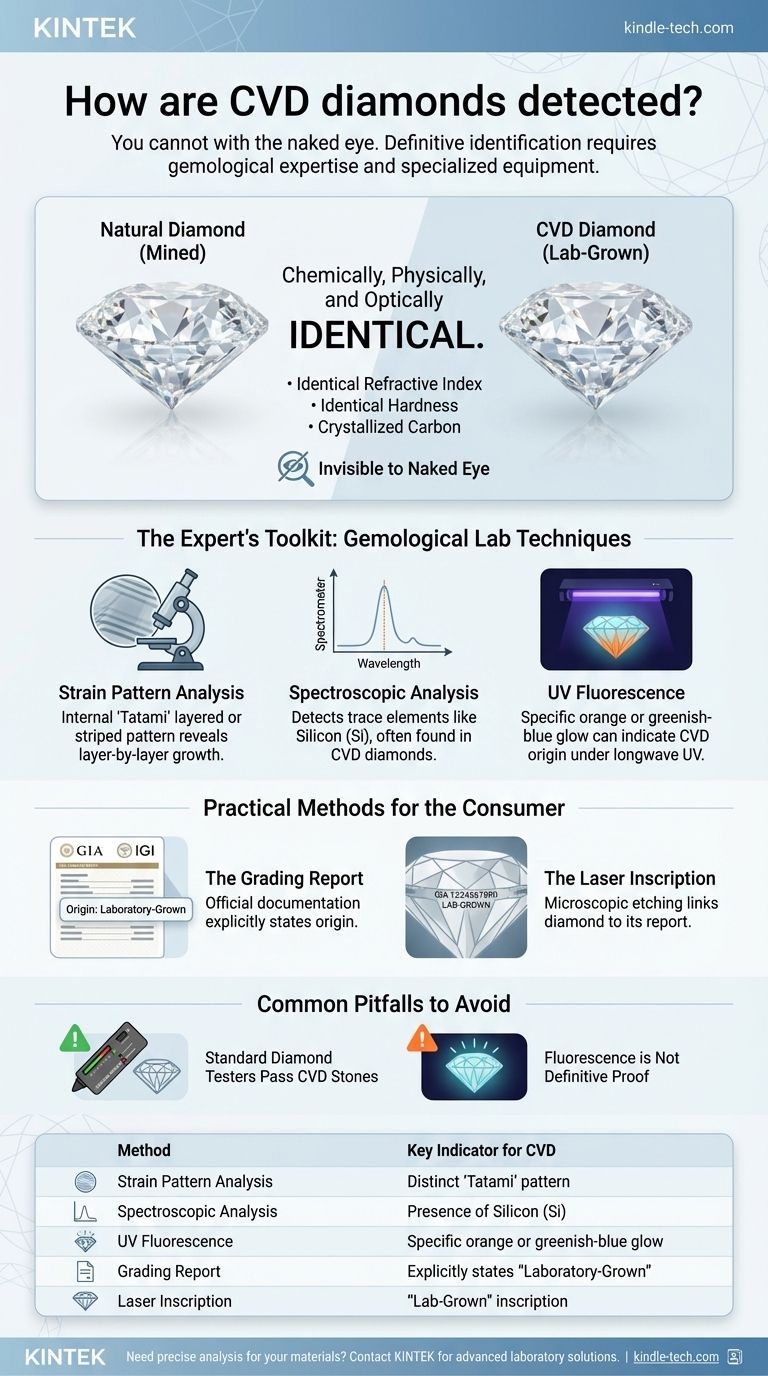

In short, you cannot. A CVD (Chemical Vapor Deposition) diamond cannot be distinguished from a natural diamond with the naked eye because they are chemically, physically, and optically identical. Definitive identification requires specialized laboratory equipment and the analysis of a trained gemologist.

The core takeaway is that while both are real diamonds, the story of their origin is told through subtle clues invisible to anyone but a specialist. For the consumer, the only reliable methods of identification are the diamond's official grading report and its laser inscription.

Why Visual Identification is Impossible

A common misconception is that a lab-grown diamond is a "fake" diamond. This is incorrect. Both natural and CVD diamonds are crystallized carbon, making them functionally the same material.

Identical Chemical and Physical Properties

A CVD diamond is not a simulant like cubic zirconia or moissanite. It possesses the same chemical composition, refractive index, and hardness as a diamond mined from the Earth. Standard handheld diamond testers that measure thermal conductivity will correctly identify a CVD diamond as a real diamond.

The "Perfect" Growth Process

The CVD process mimics natural diamond formation by growing a diamond atom-by-atom in layers. This results in a high-purity diamond crystal that lacks the tell-tale mineral inclusions often found in natural diamonds.

The Expert's Toolkit: Gemological Lab Techniques

Gemological laboratories are equipped with advanced instruments to detect the microscopic indicators of a diamond's origin. These are not simple pass/fail tests but a collection of data points that build a complete picture.

Strain Pattern Analysis

Under high magnification and using cross-polarized filters, gemologists can observe the internal strain patterns of a diamond. CVD diamonds often exhibit a specific, layered or striped strain known as a 'Tatami' pattern, which reflects their unique layer-by-layer growth process.

Spectroscopic Analysis for Trace Elements

This is one of the most definitive tests. Spectrometers analyze how a diamond interacts with light to detect the presence of trace elements. A CVD diamond may contain minute traces of silicon (Si), an element picked up during the growth process that is not typically found in natural diamonds.

Ultraviolet (UV) Fluorescence

When exposed to longwave UV light, many diamonds fluoresce (glow). While both natural and CVD diamonds can exhibit this trait, CVD diamonds sometimes display a distinct orange or greenish-blue fluorescence that can be an indicator of their origin, especially if they have undergone post-growth treatments.

Practical Methods for the Consumer

While you cannot perform lab-grade analysis, you can rely on the systems of verification and disclosure established by the jewelry industry.

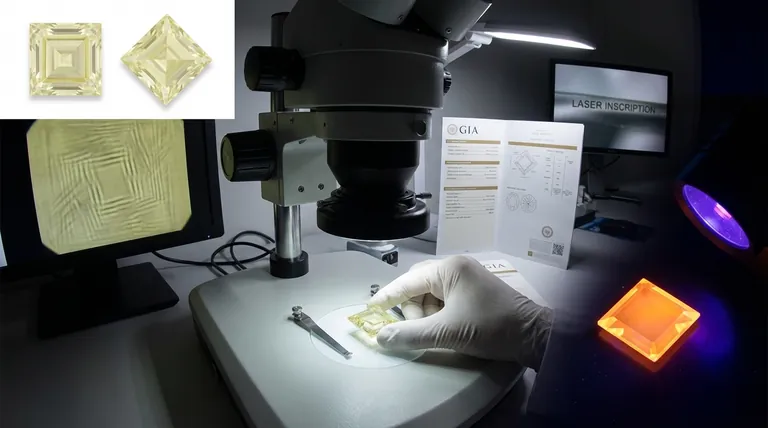

The Grading Report

Any significant diamond, whether natural or lab-grown, should be sold with a grading report from a reputable laboratory like the GIA (Gemological Institute of America) or IGI (International Gemological Institute). This report will explicitly state the diamond's origin, clearly identifying it as "Laboratory-Grown."

The Laser Inscription

To link the physical diamond to its report, graded lab-grown diamonds are typically inscribed with a microscopic laser etching on their girdle (the thin outer edge). This inscription includes the report number and often the words "Lab-Grown," providing a permanent and verifiable identifier.

Common Pitfalls to Avoid

Trusting your eyes or simple tools can be misleading. Understanding the limitations of common identification methods is key to making an informed decision.

Fluorescence Is Not Definitive Proof

Many natural diamonds fluoresce, most commonly blue. The presence of fluorescence alone is not an indicator of a lab-grown origin. It is the specific color and pattern that provides a clue for gemologists, not a standalone test.

Most "Diamond Testers" Will Pass a CVD Stone

As mentioned, basic handheld testers are designed to differentiate diamonds from simulants like glass or cubic zirconia. Since a CVD diamond is physically a diamond, these tools will register it as genuine.

Making an Informed Decision

Your approach to verifying a diamond's origin depends entirely on your situation and the information available to you.

- If your primary focus is certainty of origin when purchasing: Rely only on the official grading report and verify the matching laser inscription on the diamond's girdle.

- If your primary focus is identifying an unknown stone: The only definitive method is to submit it to a professional gemological laboratory for a full origin report.

- If your primary focus is transparency from a seller: Always ask for the diamond's documentation, as professional disclosure of lab-grown origin is the established industry standard.

Ultimately, your confidence comes not from personal inspection, but from understanding and trusting the scientific verification process.

Summary Table:

| Method | Purpose | Key Indicator for CVD Diamonds |

|---|---|---|

| Strain Pattern Analysis | Observes internal crystal structure | Distinct 'Tatami' layered/striped pattern |

| Spectroscopic Analysis | Detects trace elements | Presence of Silicon (Si) |

| UV Fluorescence | Analyzes reaction to ultraviolet light | Specific orange or greenish-blue glow |

| Grading Report | Official documentation from a lab (e.g., GIA, IGI) | Explicitly states "Laboratory-Grown" origin |

| Laser Inscription | Microscopic etching on the diamond's girdle | Report number and "Lab-Grown" inscription |

Need precise analysis for your materials?

At KINTEK, we specialize in providing advanced laboratory equipment and consumables for accurate material identification and analysis. Whether you're a gemologist, researcher, or quality control lab, our tools deliver the reliability and precision you need.

Contact our experts today to find the perfect solution for your laboratory's specific challenges!

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- CVD Diamond Optical Windows for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What are the common sources of contamination during CVD diamond growth? Improve Purity and Quality Control

- What is the main difference between CVD and natural diamond? Origin, Purity, and Value Explained

- What is the future value of lab grown diamond? Understanding Its Depreciating Financial Worth

- What is the process of lab created diamonds? A Clear Guide to HPHT & CVD Methods

- What is the difference between CVD and original diamond? Choose the Right Diamond for Your Needs