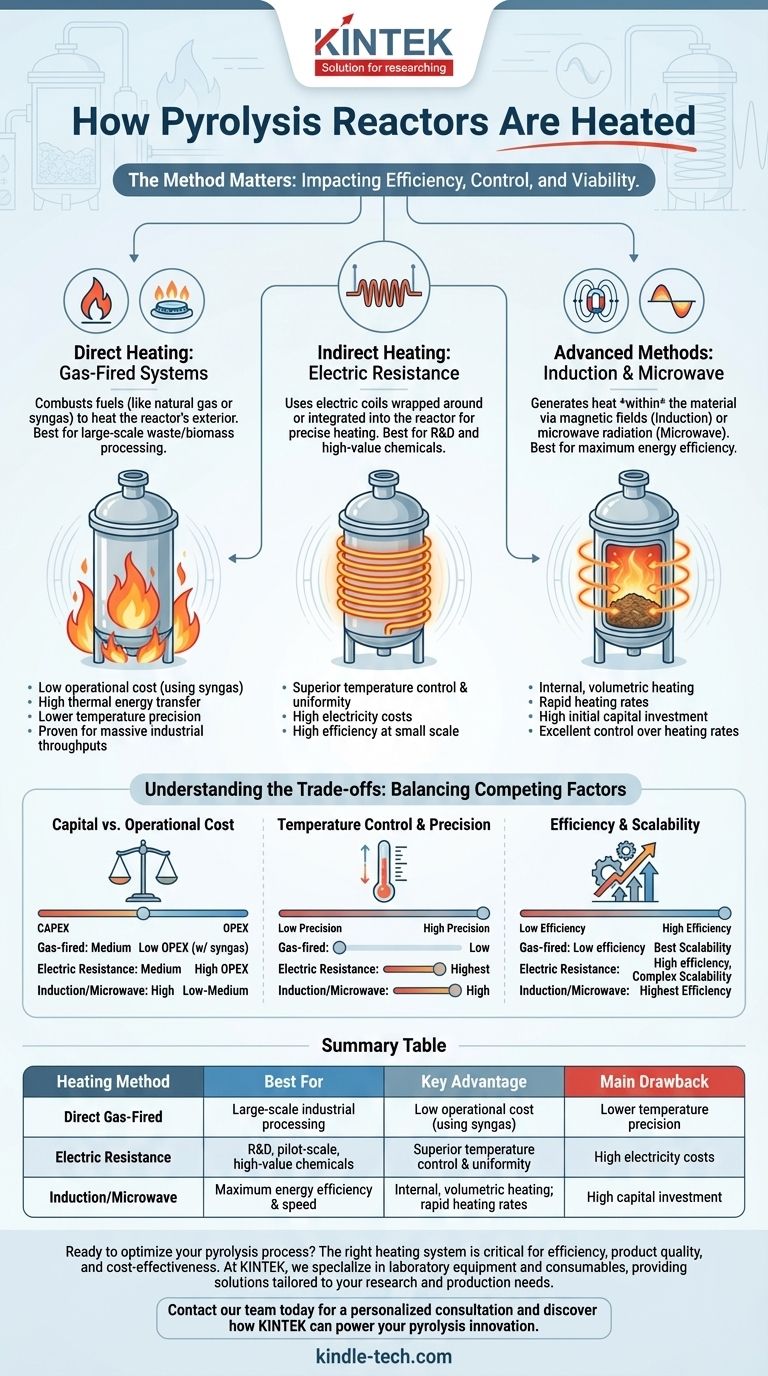

Pyrolysis reactors are primarily heated through three main methods: direct combustion of fuels, indirect electric resistance heating, and advanced electromagnetic techniques like induction. The choice is not arbitrary; it is a critical design decision that directly impacts the efficiency, control, and economic viability of the entire process.

The method used to heat a pyrolysis reactor is one of the most significant factors determining its performance. The decision involves a fundamental trade-off between operational cost, capital investment, process control precision, and scalability.

The Core Heating Mechanisms Explained

To select the right technology, you must first understand how each heating mechanism works and the inherent advantages and disadvantages it brings.

Direct Heating: Gas-Fired Systems

This is a conventional and robust method, common in large-scale industrial plants. Fuel—such as natural gas or even the syngas produced by the pyrolysis process itself—is combusted, and the hot flue gases are used to heat the exterior of the reactor vessel.

This direct application of flame and hot gas transfers a massive amount of thermal energy, making it suitable for processing large volumes of feedstock like municipal solid waste or biomass.

Indirect Heating: Electric Resistance

Electric resistance heating is the standard for laboratory and pilot-scale reactors where precision is paramount. In this setup, high-resistance electric coils are wrapped around the reactor chamber or integrated into a jacket.

As electricity passes through the coils, they heat up, transferring thermal energy conductively and radiatively to the reactor wall. This provides exceptionally uniform and precisely controlled heat, which is crucial for research and the production of high-value specialty chemicals.

Advanced Methods: Induction and Microwave

These methods represent a more sophisticated approach to heating by generating heat within the material itself, rather than applying it to an external surface.

Induction heating uses a powerful alternating magnetic field. This field induces electrical eddy currents directly within the conductive metal wall of the reactor or in conductive particles (like biochar) mixed with the feedstock, generating rapid and efficient heat.

Microwave heating works differently, using microwave radiation to selectively and volumetrically heat materials that are good absorbers. In pyrolysis, this is often the carbonaceous char, which becomes a network of microscopic "hot spots" that drive the reaction from the inside out.

Understanding the Trade-offs

There is no single "best" heating method. The optimal choice is a balance of competing factors, and understanding these trade-offs is key to making an informed decision.

Capital Cost vs. Operational Cost

A gas-fired system typically has a moderate capital cost but a variable operational cost tied directly to fuel prices. However, if it can run on the inexpensive by-product gas from the pyrolysis itself, it becomes extremely cost-effective.

Electric resistance systems have a moderate capital cost but often the highest operational cost due to commercial electricity rates. Induction and microwave systems have the highest initial capital cost due to their complexity, but can offer lower long-term operational costs through superior energy efficiency.

Temperature Control and Precision

This is where the methods differ most significantly. Electric resistance offers the best precision and uniformity, making it ideal for sensitive processes.

Induction heating also provides excellent, rapid control over heating rates. Gas-fired systems are the least precise, suffering from thermal inertia (slow to heat up and cool down) and the risk of creating localized "hot spots" on the reactor wall that can lead to inconsistent product quality.

Heat Transfer Efficiency and Scalability

Induction and microwave heating are the most efficient, as they generate heat directly where it is needed, minimizing thermal losses to the environment.

Gas-fired systems are the least efficient due to significant heat loss in exhaust flue gases, but they are the most proven for scaling to massive industrial throughputs. Electric resistance is highly efficient at a small scale, but becomes increasingly complex and costly to scale up.

Making the Right Choice for Your Goal

Your choice of heating technology should be dictated by your primary objective.

- If your primary focus is large-scale waste processing or biomass conversion: A gas-fired system is often the most practical and economical choice, especially if you can utilize the produced syngas to power the reactor.

- If your primary focus is research, development, or producing high-value chemicals: The unparalleled precision of electric resistance heating is essential for achieving consistent, repeatable, and high-quality results.

- If your primary focus is achieving maximum energy efficiency and rapid reaction rates: Induction or microwave heating offer superior performance, provided you can justify the higher initial investment and technical complexity.

Ultimately, aligning your heating strategy with your specific process goals is the foundation of a successful and economically viable pyrolysis operation.

Summary Table:

| Heating Method | Best For | Key Advantage | Main Drawback |

|---|---|---|---|

| Direct Gas-Fired | Large-scale industrial processing | Low operational cost (using syngas) | Lower temperature precision |

| Electric Resistance | R&D, pilot-scale, high-value chemicals | Superior temperature control & uniformity | High electricity costs |

| Induction/Microwave | Maximum energy efficiency & speed | Internal, volumetric heating; rapid heating rates | High capital investment |

Ready to optimize your pyrolysis process? The right heating system is critical for efficiency, product quality, and cost-effectiveness. At KINTEK, we specialize in laboratory equipment and consumables, providing solutions tailored to your research and production needs. Let our experts help you select the perfect reactor heating technology for your specific application.

Contact our team today for a personalized consultation and discover how KINTEK can power your pyrolysis innovation.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy