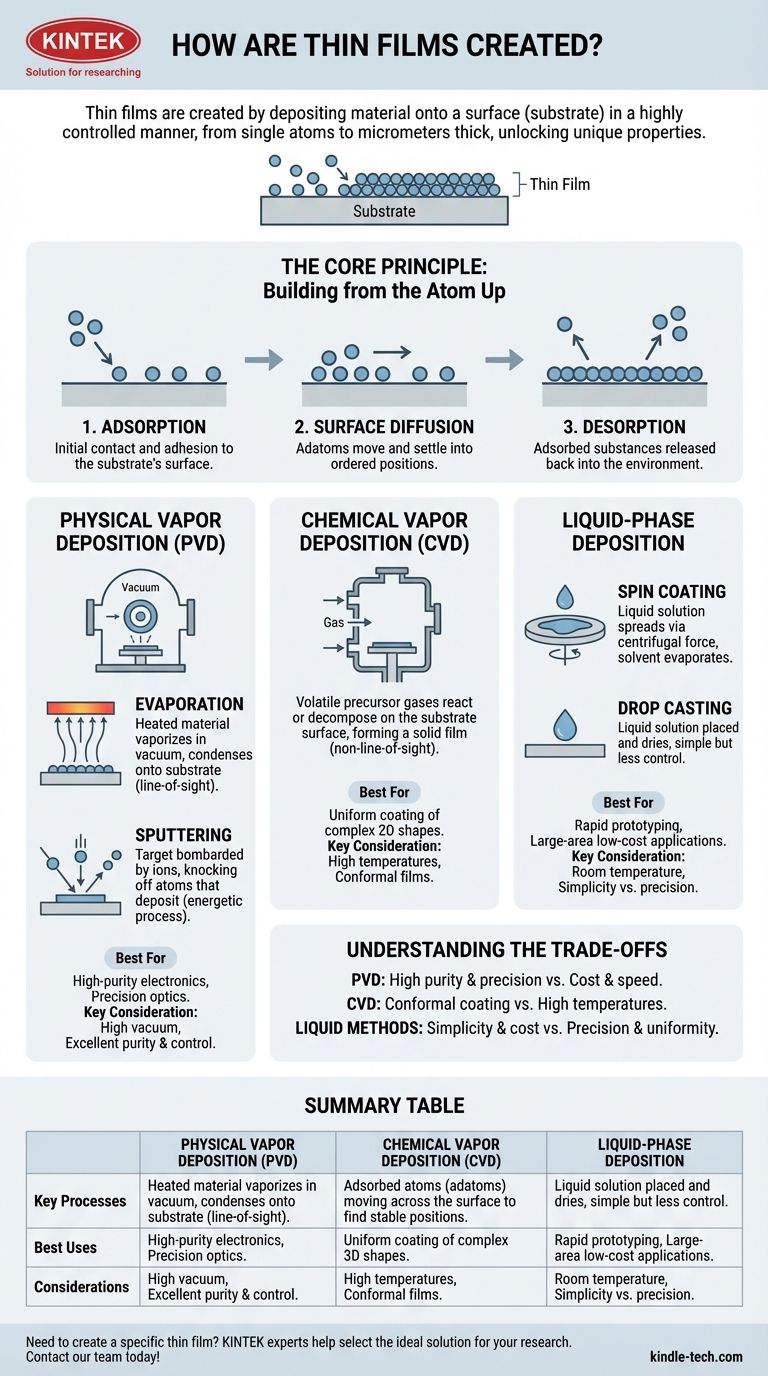

Thin films are created by depositing material onto a surface, known as a substrate, in a highly controlled manner. The goal is to build a layer that can be as thin as a single atom or up to several micrometers thick, unlocking unique properties not found in the bulk material. The most common methods fall into three broad categories: physical deposition, chemical deposition, and liquid-phase deposition.

The specific method used to create a thin film is not arbitrary; it is a deliberate choice dictated by the final application. The decision hinges on the required purity, thickness control, material properties, and the shape of the object being coated.

The Core Principle: Building from the Atom Up

Before examining specific techniques, it's crucial to understand the fundamental actions that occur at the atomic level during film growth. These processes are the foundation of all deposition methods.

Adsorption: The Foundation of Growth

Adsorption is the initial step where atoms, ions, or molecules from a gas or liquid make contact and adhere to the substrate's surface. This is the very beginning of the film's formation.

Surface Diffusion: Arranging the Building Blocks

Once adsorbed onto the surface, these atoms (now called "adatoms") are not necessarily locked in place. They often possess enough energy to move across the surface, a process called surface diffusion, allowing them to settle into more stable, ordered positions.

Desorption: The Imperfect Process

Deposition is not a perfectly efficient process. Desorption occurs when a previously adsorbed substance is released from the surface, either because it failed to form a strong bond or was knocked off by another incoming particle.

Major Deposition Categories: A Practical Guide

The various techniques for creating thin films can be grouped by the state of matter they use to transport material to the substrate: vapor (physical or chemical) or liquid.

Physical Vapor Deposition (PVD)

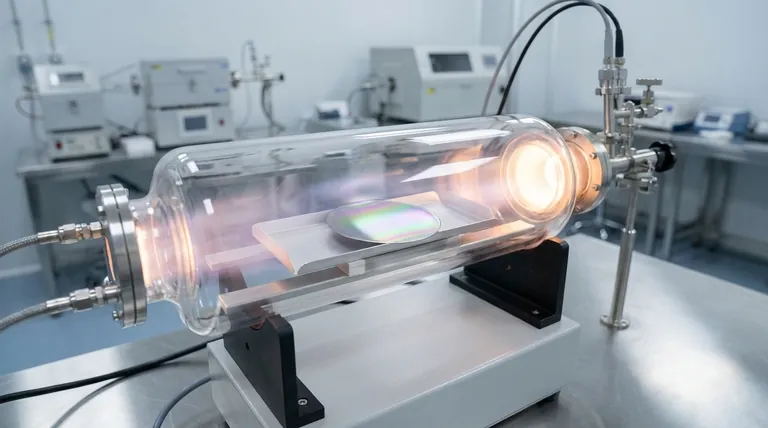

PVD refers to a family of processes where a solid material is vaporized in a vacuum and then condenses onto the substrate to form the film.

Evaporation involves heating a target material in a vacuum chamber until it evaporates into a gas. This gas then travels in a straight line until it coats the cooler substrate, much like how steam condenses on a cold surface.

Sputtering is a more energetic process. Here, a target is bombarded with high-energy ions (typically from a gas like argon). This bombardment acts like an atomic-scale sandblaster, knocking atoms off the target, which then travel and deposit onto the substrate.

Chemical Vapor Deposition (CVD)

In CVD, the substrate is placed in a chamber and exposed to one or more volatile precursor gases. These gases react or decompose on the substrate's surface, leaving behind a solid film. Unlike PVD, CVD is not a "line-of-sight" process, making it excellent for coating complex, non-flat surfaces evenly.

Liquid-Phase Deposition

These methods use a liquid containing the desired material to coat the substrate. They are often simpler and less expensive than vapor-based techniques.

Spin Coating is a common technique where a small amount of a material solution is dropped onto the center of a spinning substrate. Centrifugal force spreads the liquid into a thin, uniform layer, and the solvent then evaporates, leaving the film behind.

Drop Casting is the simplest method. A drop of the material solution is placed on the substrate and allowed to dry. This technique is fast and easy but offers the least control over film thickness and uniformity.

Understanding the Trade-offs

No single deposition method is universally superior. The choice involves a critical assessment of the trade-offs between cost, quality, and material compatibility.

PVD: Purity vs. Complexity

PVD methods, especially sputtering, can produce exceptionally pure and dense films with precise thickness control. However, they require expensive high-vacuum equipment and can be relatively slow processes.

CVD: Conformal Coating vs. High Temperatures

CVD's primary advantage is its ability to produce highly conformal films that coat even complex 3D shapes uniformly. The main drawback is that many CVD processes require high temperatures, which can damage sensitive substrates like plastics or certain electronic components.

Liquid Methods: Simplicity vs. Precision

Spin coating and drop casting are prized for their low cost, high speed, and ability to operate at room temperature. Their limitation is a general lack of precision in controlling film thickness, uniformity, and purity compared to vapor deposition methods.

Making the Right Choice for Your Goal

The optimal deposition technique is directly linked to the intended application of the thin film, whether it's for optical, electrical, or protective purposes.

- If your primary focus is high-purity electronics or precision optics: Vapor deposition methods like sputtering and CVD are the industry standard for their unparalleled control over film properties.

- If your primary focus is coating a complex 3D shape uniformly: Chemical Vapor Deposition (CVD) is often the superior choice due to its non-line-of-sight nature.

- If your primary focus is rapid prototyping or large-area, low-cost applications (like some flexible solar cells): Liquid-based methods like spin coating offer an excellent balance of speed and simplicity.

Ultimately, mastering thin film creation is about selecting the right tool to engineer material properties at the atomic scale.

Summary Table:

| Method Category | Key Process | Best For | Key Consideration |

|---|---|---|---|

| Physical Vapor Deposition (PVD) | Evaporation, Sputtering | High-purity electronics, Precision optics | High vacuum, Excellent purity & control |

| Chemical Vapor Deposition (CVD) | Gas reaction on substrate | Uniform coating of complex 3D shapes | High temperatures, Conformal films |

| Liquid-Phase Deposition | Spin Coating, Drop Casting | Rapid prototyping, Large-area low-cost applications | Room temperature, Simplicity vs. precision |

Need to create a specific thin film for your project? The right deposition method is critical for performance. KINTEK specializes in lab equipment and consumables for all thin film applications. Our experts can help you select the ideal PVD, CVD, or liquid-phase solution to achieve the purity, thickness, and uniformity your research demands. Contact our team today to discuss your specific substrate and material requirements!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty