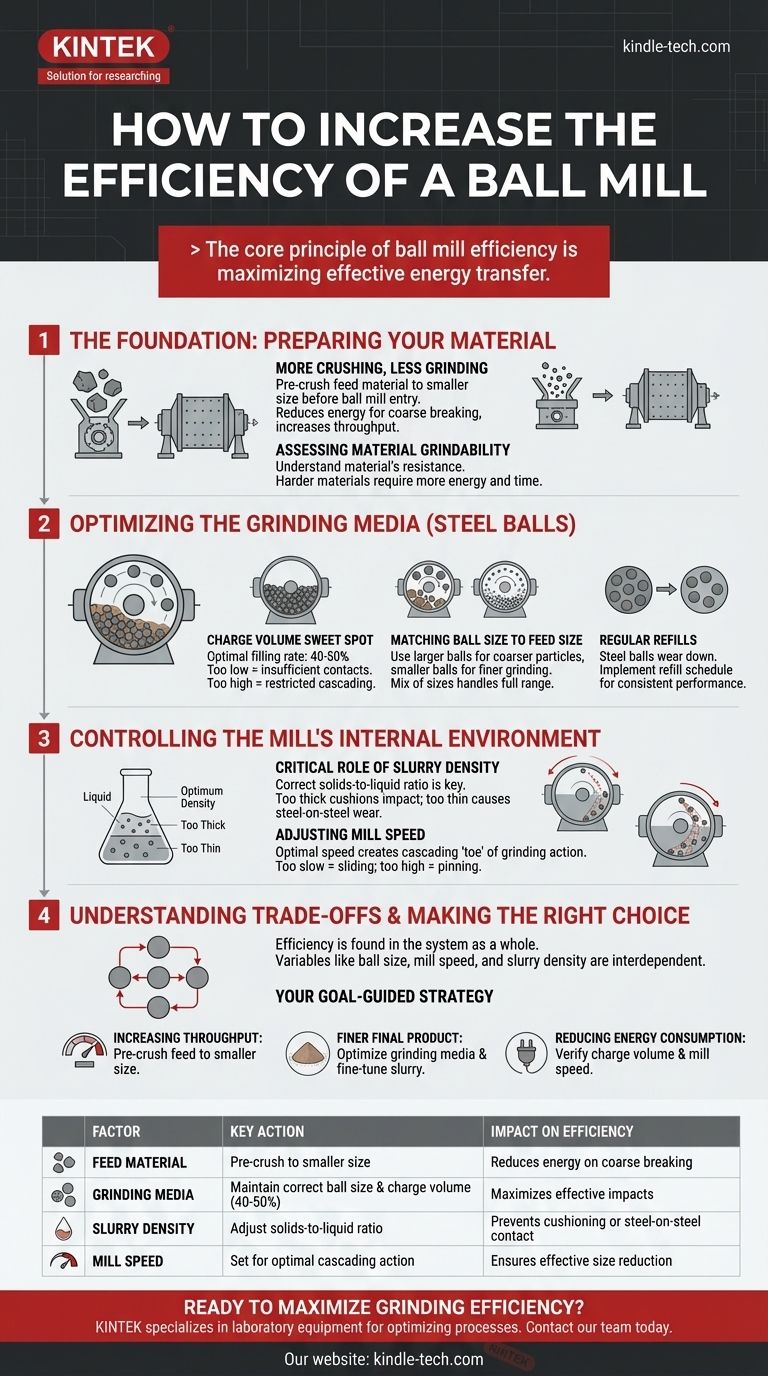

To increase the efficiency of a ball mill, you must systematically optimize the relationship between the material you are grinding and the media doing the grinding. This involves controlling the feed size, the volume and size of the steel balls, and the density of the slurry inside the mill. Each factor directly impacts how much energy is productively used for particle size reduction versus how much is wasted.

The core principle of ball mill efficiency is maximizing effective energy transfer. Every adjustment—from the size of the material entering the mill to the density of the slurry—is about ensuring the steel balls strike the target material with the greatest possible efficacy, rather than wasting energy on ineffective collisions or internal friction.

The Foundation: Preparing Your Material

Before the material even enters the mill, you can make significant gains in efficiency. The state of your feed material sets the baseline for the entire grinding process.

The Principle of "More Crushing, Less Grinding"

The most significant efficiency gain often comes from reducing the particle size of the feed material before it enters the ball mill. Ball mills are most efficient at fine grinding, not coarse breaking.

By using a crusher to do the initial size reduction, you allow the ball mill to focus its energy on its intended task. This single change can drastically increase throughput and lower overall energy consumption.

Assessing Material Grindability

Every material has an inherent grindability, or resistance to being broken down. While you may not be able to change the material itself, understanding this property is crucial for setting realistic expectations and optimizing other parameters accordingly.

Harder materials will always require more energy and time, which must be factored into your process calculations.

Optimizing the Grinding Media (The Steel Balls)

The steel balls, or grinding media, are the engine of the mill. Their size, volume, and condition are the most critical variables you can control within the mill itself.

The "Charge Volume" Sweet Spot

The filling rate, or charge volume, is the percentage of the mill's internal volume occupied by the steel balls. The optimal range is typically 40-50%.

If the charge is too low, the number of grinding contacts per rotation is insufficient, wasting time and energy. If it's too high, the balls cannot cascade freely, reducing the impact force and grinding action.

Matching Ball Size to Feed Size

There is no one-size-fits-all solution for grinding media. You must match the ball size to the material you are grinding.

Use larger balls for breaking down coarser feed particles and smaller balls for finer grinding of smaller particles. An optimized charge often uses a mix of sizes to handle the full range of particles as they are reduced.

Maintaining the Charge Through Regular Refills

Steel balls wear down over time, becoming smaller and less effective. This wear reduces the total charge volume and skews the size distribution.

Implementing a schedule for accurately refilling the mill with new balls is essential for maintaining consistent and predictable grinding performance.

Controlling the Mill's Internal Environment

The conditions inside the mill—specifically the slurry density and rotation speed—dictate how the balls and material interact.

The Critical Role of Slurry Density

Grinding is most often done in a wet environment, and the slurry density (the ratio of solids to liquid) is a key lever.

If the slurry is too thick, it will cushion the impact of the balls, reducing grinding efficiency. If it's too thin, it won't properly coat the media, leading to wasted energy from steel-on-steel contact.

Adjusting Mill Speed for Proper Action

The rotational speed of the mill determines the behavior of the ball charge. If the speed is too slow, the balls will just slide, providing little grinding.

If the speed is too high (approaching "critical speed"), the balls will be pinned to the mill wall by centrifugal force, and no grinding will occur. The most efficient speed allows the charge to rise and cascade, creating a "toe" of intense grinding action.

Understanding the Trade-offs

Optimizing a ball mill is not about maximizing one variable but about finding the right balance for your specific application.

The Interdependence of Variables

All these factors are interconnected. Changing the ball size might require you to adjust the mill speed. Reducing the feed size may allow you to use a different slurry density for better results. Efficiency is found in the system as a whole, not in a single component.

Wear and Tear as an Inevitable Cost

Grinding is an inherently abrasive and high-impact process. While these strategies will improve energy efficiency, they will not eliminate the operational costs of replacing the steel ball media and the mill's internal liners, which are designed to be consumed over time.

Making the Right Choice for Your Goal

Your optimization strategy should be guided by your primary objective.

- If your primary focus is increasing throughput: Pre-crushing the feed material to a smaller, more consistent size is the most effective strategy.

- If your primary focus is achieving a finer final product: Concentrate on optimizing the grinding media with a proper distribution of smaller ball sizes and fine-tuning the slurry density.

- If your primary focus is reducing energy consumption: First, verify your ball charge volume and mill speed are correct to ensure you are not wasting energy on poor cascading action.

Ultimately, a highly efficient ball mill is a balanced system where every component is tuned to maximize productive energy transfer.

Summary Table:

| Factor to Optimize | Key Action | Impact on Efficiency |

|---|---|---|

| Feed Material | Pre-crush to smaller size | Reduces energy spent on coarse breaking |

| Grinding Media | Maintain correct ball size & charge volume (40-50%) | Maximizes effective impacts and grinding action |

| Slurry Density | Adjust solids-to-liquid ratio | Prevents energy-wasting cushioning or steel-on-steel contact |

| Mill Speed | Set for optimal cascading action | Ensures balls lift and fall effectively for size reduction |

Ready to maximize your grinding efficiency and reduce operational costs?

KINTEK specializes in laboratory equipment and consumables for optimizing processes like ball milling. Our experts can help you select the right grinding media and provide insights to fine-tune your mill's parameters for your specific material and goals.

Contact our team today to discuss how we can support your lab's productivity and efficiency.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- How does high-energy ball milling equipment contribute to the age hardening of aluminum alloys? Boost Alloy Strength

- How do you calculate ball mill residence time? Master Throughput and Product Fineness

- What is the role of the planetary ball mill in the synthesis of LATP? Master Solid Electrolyte Prep

- What is the primary role of a planetary ball mill in LLZ-CaSb synthesis? Achieve Perfect Precursor Homogeneity

- What is the function of a variable-frequency planetary ball mill in the preparation of copper-based electrical contact composites?

- What role does a planetary ball mill play in the preparation of nano-sized Li8/7Ti2/7V4/7O2 cathode materials?

- What are the advantages of using ball mills for halide electrolytes? Achieve Superior Ionic Conductivity with KINTEK

- What is the specific role of a high-energy planetary ball mill in the synthesis of Ag-doped sulfide solid-state electrolytes?