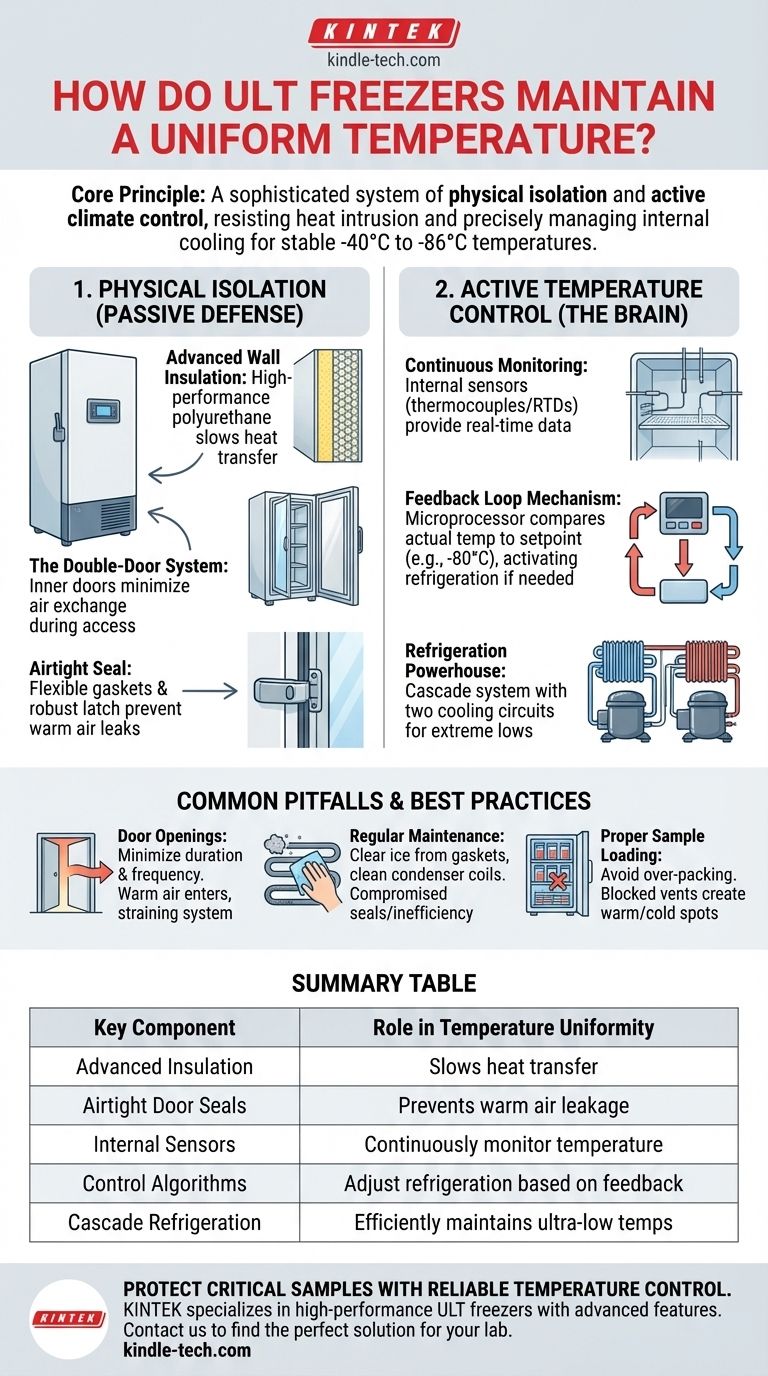

At their core, ultra-low temperature (ULT) freezers maintain uniform temperature through a sophisticated system of physical isolation and active climate control. This is achieved by combining advanced insulation and airtight seals to prevent heat from entering, while an intelligent network of sensors and control algorithms continuously monitors and adjusts the internal refrigeration cycle to hold a precise, stable temperature, typically between -40°C and -86°C.

The key to a ULT freezer's stability is not just its power to get cold, but its design to resist temperature change. It achieves uniformity through a constant, dynamic balance between aggressively preventing heat intrusion and precisely managing its internal cooling system.

The First Line of Defense: Physical Isolation

To maintain temperatures colder than an Antarctic winter, a ULT freezer must first be a fortress against the ambient heat of the laboratory. This is accomplished through its physical construction.

Advanced Wall Insulation

The cabinet walls are injected with high-performance insulation, typically a dense polyurethane material. This dramatically slows the process of heat transfer from the outside environment into the freezer's interior.

The Double-Door System

ULT freezers feature a heavy, insulated outer door and multiple inner doors. The primary function of the inner doors is to minimize the exchange of cold and warm air when accessing samples, protecting the overall environment from significant temperature fluctuations.

Creating an Airtight Seal

The main door is sealed with flexible, silicone-based gaskets that create an airtight barrier. A robust external latching mechanism ensures the door is pulled tight against these seals, preventing any warm air from leaking into the unit.

The Brain of the Operation: Active Temperature Control

While physical barriers are critical, they are passive. The active management of the internal climate is what ensures true temperature uniformity.

Continuous Temperature Monitoring

Internal sensors, known as thermocouples or RTDs, are placed strategically within the freezer chamber. These devices provide constant, real-time temperature data to the central controller.

The Feedback Loop Mechanism

This sensor data feeds into a microprocessor-based control system. Using control algorithms, the system compares the actual internal temperature to the desired setpoint (e.g., -80°C).

If the temperature rises even slightly, the controller activates the refrigeration system to bring it back down. If it's at the setpoint, the system remains in a low-power or standby state. This constant cycle of monitoring and adjusting is the core feedback loop.

The Refrigeration Powerhouse

The control system commands a powerful, specialized refrigeration system. Unlike a standard freezer, ULT units often use a cascade refrigeration system with two separate cooling circuits to efficiently and reliably reach and maintain extremely low temperatures.

Common Pitfalls and Best Practices

The freezer's design is only half the battle. User practices and maintenance play a critical role in maintaining temperature uniformity and ensuring the longevity of the unit and its samples.

The Impact of Door Openings

Every time the outer door is opened, warm, moist air enters the unit, forcing the system to work harder. Minimizing the duration and frequency of door openings is the single most important user practice.

The Importance of Regular Maintenance

Ice buildup, particularly around the door gaskets, can compromise the seal. Regularly clearing this ice away is essential to prevent warm air leaks. Likewise, cleaning the condenser coils ensures the refrigeration system can dissipate heat effectively and run efficiently.

Proper Sample Loading

Over-packing the freezer or blocking air vents can impede internal air circulation. This can create warmer and colder spots within the cabinet, compromising temperature uniformity for all samples stored inside.

Making the Right Choice for Your Goal

Understanding how a ULT freezer operates allows you to develop protocols that maximize sample security and equipment reliability.

- If your primary focus is sample integrity: Prioritize minimizing door opening times and train all users on proper closing and latching procedures to ensure a perfect seal.

- If your primary focus is long-term reliability: Implement a strict maintenance schedule for cleaning gaskets and condenser filters to prevent system strain.

- If your primary focus is operational efficiency: Organize sample racks and inventory logically to ensure users can find what they need quickly, reducing the time the door stays open.

By combining this advanced technology with disciplined lab practices, you can ensure your critical biological materials remain stable and protected.

Summary Table:

| Key Component | Role in Temperature Uniformity |

|---|---|

| Advanced Insulation | Slows heat transfer from the lab environment |

| Airtight Door Seals | Prevents warm air leakage into the freezer |

| Internal Sensors | Continuously monitor temperature in real-time |

| Control Algorithms | Adjust refrigeration based on sensor feedback |

| Cascade Refrigeration | Efficiently maintains ultra-low temperatures |

Ensure your lab's critical samples are protected with reliable temperature control. KINTEK specializes in high-performance lab equipment, including ultra-low temperature freezers designed for precision and durability. Our solutions help laboratories maintain sample integrity with advanced features like robust insulation, intelligent monitoring, and energy-efficient cooling systems. Contact us today to find the perfect ULT freezer for your laboratory needs and benefit from our expertise in supporting research and storage goals.

Visual Guide

Related Products

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency