At their core, ultra-low temperature (ULT) freezers achieve their extreme temperatures by using a multi-stage cooling process. Unlike a standard household freezer that uses a single refrigeration system, a ULT freezer employs a cascade refrigeration system, which links two independent cooling circuits together in series to systematically remove heat and reach temperatures as low as -80°C.

The critical insight is that a ULT freezer doesn't use one overwhelmingly powerful cooling system. Instead, it uses two separate systems in a relay: the first system cools the second, enabling the second system to begin its own cooling cycle from a much lower starting point and achieve ultra-low temperatures.

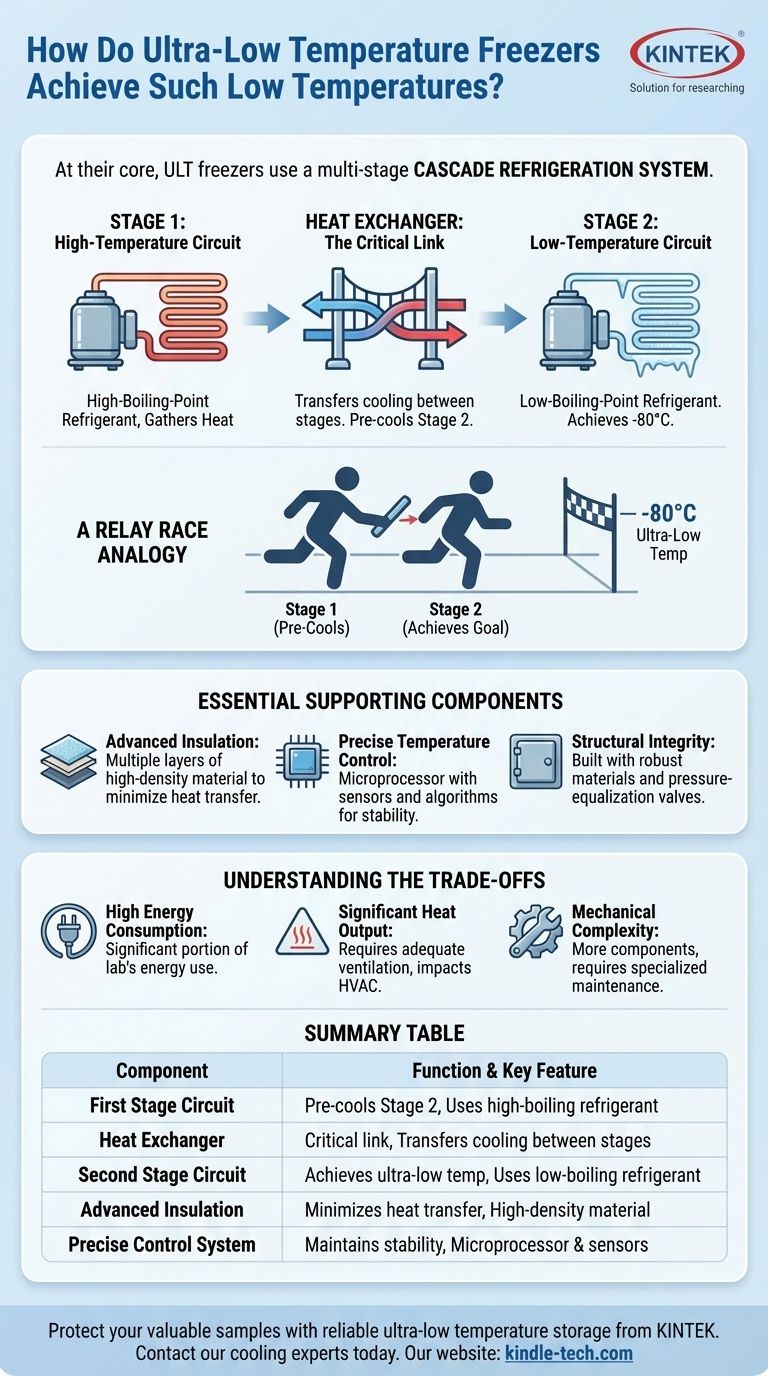

The Core Technology: The Cascade Refrigeration System

The cascade system is the engineering principle that separates a ULT freezer from a conventional one. It is essentially two refrigeration units working as a team, with the output of the first becoming the input for the second.

The First Stage (High-Temperature Circuit)

This initial circuit functions much like a standard freezer. It uses a compressor and a high-boiling-point refrigerant to gather heat.

However, instead of cooling the freezer's internal chamber directly, its sole purpose is to cool the components of the second stage.

The Heat Exchanger: The Critical Link

This component is the bridge between the two circuits. The first stage's cold refrigerant flows through the heat exchanger, absorbing heat from the refrigerant in the second stage.

This process "pre-cools" the second refrigerant, giving it a significant head start in its own cooling cycle.

The Second Stage (Low-Temperature Circuit)

Because it has been pre-cooled, the second circuit can use a specialized, low-boiling-point refrigerant.

This second compressor can now efficiently remove the remaining heat from the freezer's insulated chamber, pulling the internal temperature down to its target of -80°C or below.

A Relay Race Analogy

Think of it as a two-person relay race. The first runner (Stage 1) takes the baton (heat) from the starting line and runs a lap.

They then hand the baton off to the second runner (Stage 2) at the heat exchanger. Because the second runner didn't have to start from a standstill, they have the energy to complete the final, much more difficult lap and cross the finish line at an ultra-low temperature.

Essential Supporting Components

Achieving and maintaining such extreme cold requires more than just the cascade system. The entire unit is engineered for thermal stability and reliability.

Advanced Insulation

To minimize heat transfer from the outside environment, ULT freezers use multiple layers of high-density, heavy-duty insulation. This is far thicker and more effective than what is found in consumer-grade appliances.

Precise Temperature Control

These freezers are not just cold; they are consistently cold. Sensors constantly monitor the internal temperature, feeding data to a microprocessor.

This control system uses sophisticated algorithms to make micro-adjustments to the cascade system, ensuring the temperature remains stable and within a very narrow range.

Structural Integrity

The extreme temperature difference between the inside and outside of the freezer creates immense physical stress.

ULT freezers are built with robust materials, reinforced inner doors, and heated pressure-equalization valves to prevent vacuum-sealing and frost buildup, ensuring both durability and easy access.

Understanding the Trade-offs

The engineering that enables ultra-low temperatures also introduces specific operational considerations that are critical to understand.

High Energy Consumption

Running two independent refrigeration compressors in series is an energy-intensive process. ULT freezers represent a significant portion of a laboratory's energy consumption.

Significant Heat Output

The heat removed from the freezer's interior, along with the waste heat from the compressors, must be dissipated into the surrounding room. This requires adequate ventilation and often impacts a facility's HVAC load.

Mechanical Complexity

A cascade system contains twice the number of compressors, refrigerants, and expansion valves as a standard freezer. This complexity increases the number of potential failure points and requires specialized technicians for maintenance and repair.

Making the Right Choice for Your Goal

Understanding the technology behind a ULT freezer allows you to manage it more effectively and protect your invaluable samples.

- If your primary focus is sample security: The stability and power of the cascade system are paramount, justifying the energy costs.

- If your primary focus is operational efficiency: Ensure the freezer is placed in a well-ventilated area to help the system dissipate heat, and perform regular maintenance like cleaning filters and checking door seals.

- If your primary focus is long-term reliability: A preventative maintenance schedule is non-negotiable to monitor both cooling circuits and catch potential issues before a catastrophic failure.

Ultimately, knowing that your freezer relies on an interconnected, two-stage system empowers you to better safeguard the critical materials stored within it.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| First Stage Circuit | Pre-cools the second stage | Uses high-boiling-point refrigerant |

| Heat Exchanger | Transfers cooling between stages | Critical link enabling lower temperatures |

| Second Stage Circuit | Achieves ultra-low temperatures | Uses low-boiling-point refrigerant |

| Advanced Insulation | Minimizes heat transfer | Multiple layers of high-density material |

| Precise Control System | Maintains temperature stability | Microprocessor with sensors and algorithms |

Protect your valuable samples with reliable ultra-low temperature storage from KINTEK.

As specialists in laboratory equipment, KINTECO provides ULT freezers with advanced cascade refrigeration technology that ensures precise temperature control down to -80°C. Our freezers are engineered for maximum sample security, energy efficiency, and long-term reliability—critical for research labs, biobanks, and pharmaceutical facilities.

Contact our cooling experts today to discuss your specific ULT freezer requirements and discover how KINTECO can support your laboratory's unique needs with dependable temperature control solutions.

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

People Also Ask

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What is the role of an ultra-low temperature (ULT) freezer in the freeze-thaw synthesis of hydrogel nanocomposites?

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation