To maintain vacuum pressure, you must ensure the rate of gas being removed from your system by the vacuum pump is equal to or greater than the rate of gas entering the system. This involves selecting the correct pump for your target pressure and actively minimizing all sources of incoming gas, which primarily consist of physical leaks and the outgassing of materials within the chamber. Continuous monitoring with a vacuum gauge is essential to verify that this balance is being successfully maintained.

The core challenge of maintaining vacuum is not just about the pump; it's a battle against an invisible influx of gas. Your success depends on systematically eliminating leaks and choosing clean, low-outgassing materials to create a truly isolated environment.

The Fundamentals of Vacuum Pressure

A stable vacuum is achieved when you reach equilibrium between gas removal and gas addition. Understanding these two opposing forces is the key to control.

The Pumping vs. Gas Load Equation

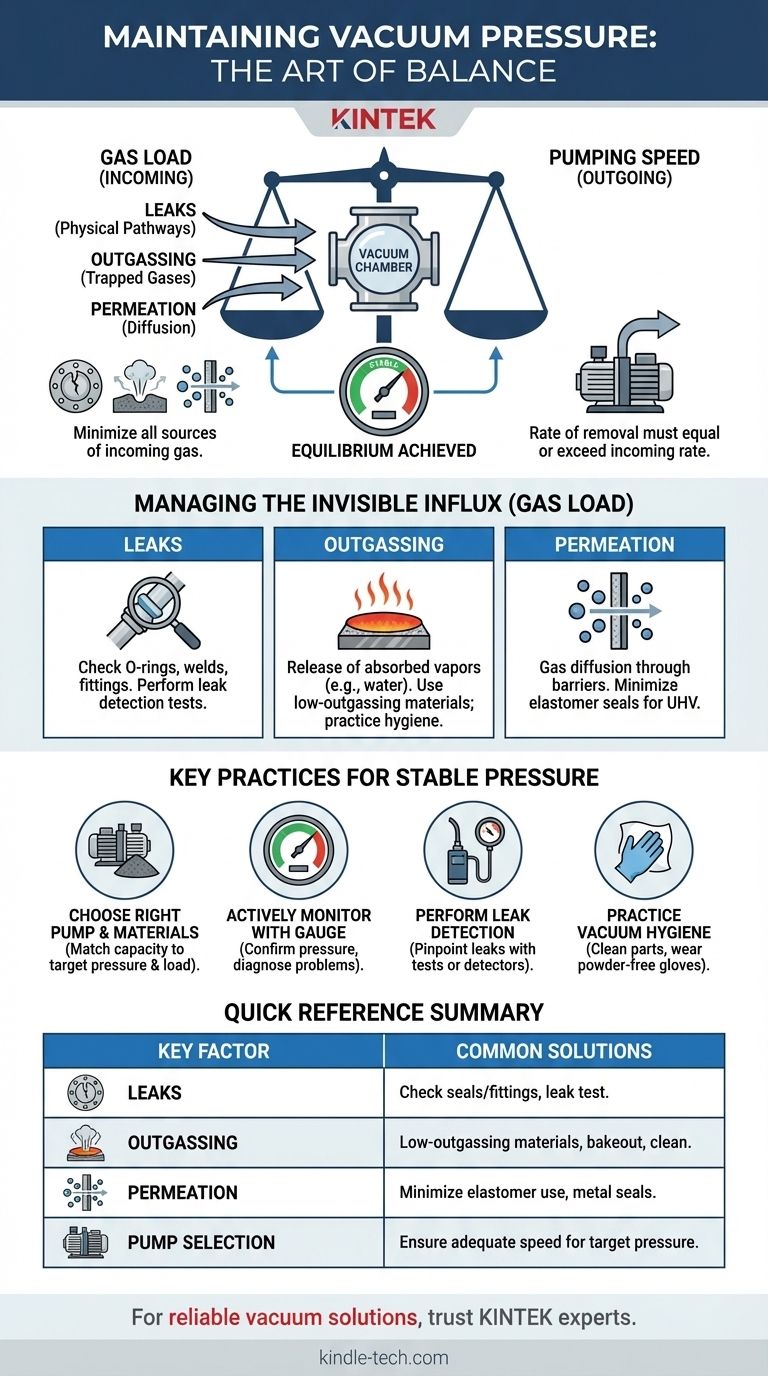

Every vacuum system is governed by a simple relationship: Pumping Speed vs. Gas Load.

Pumping Speed is the volume of gas your vacuum pump can remove per unit of time (e.g., liters per second).

Gas Load is the total rate at which gas molecules enter your vacuum chamber from all sources. A stable pressure is reached when the pump's removal rate exactly matches this incoming gas load.

Constant Pumping Does Not Guarantee Constant Pressure

Simply leaving the pump running is not enough. If the gas load increases (for example, a new leak appears or the temperature rises, increasing outgassing), the pressure inside your chamber will rise, even if the pump is working perfectly.

Identifying and Controlling the Gas Load

Your primary task in maintaining vacuum is to minimize the gas load. This gas comes from three main sources.

Leaks: The Obvious Culprit

Leaks are physical pathways for gas from the outside atmosphere to enter your vacuum chamber. They are often the first suspect when pressure is unstable.

Common leak points include improperly seated O-rings, faulty welds, cracks in components, or loose fittings and flanges. Even microscopic cracks can represent a significant gas load in high-vacuum systems.

Outgassing: The Hidden Foe

Outgassing is the release of gases or vapors that were absorbed or trapped within the materials of your vacuum chamber. This is a critical and often underestimated source of gas load.

Water vapor is the most common outgassing substance, clinging to virtually all internal surfaces. Other sources include oils, solvents from cleaning, and gases trapped within porous materials. This is why material choice is so important.

Permeation: Gas Through Solid Barriers

Permeation is the process of gas diffusing directly through a solid material. While it seems counterintuitive, gases like helium and hydrogen can slowly pass through materials like elastomers (O-rings) and even thin glass or metal walls.

This is a primary concern in ultra-high vacuum (UHV) applications, where every molecule counts.

Key Practices for Maintaining Pressure

Achieving a stable vacuum requires a systematic approach to both system design and operation.

Choose the Right Pump and Materials

The pump's capacity must be sufficient to handle the expected gas load and reach your target pressure. More importantly, construct your chamber from vacuum-compatible materials with low outgassing rates, such as stainless steel or borosilicate glass, and minimize the use of plastics and porous ceramics.

Actively Monitor with a Vacuum Gauge

A vacuum gauge is your window into the system. It does not maintain pressure on its own, but it allows you to see the effect of your actions in real time.

Use the gauge to confirm you have reached your target pressure and to diagnose problems. A pressure that slowly rises after isolating the chamber from the pump is a clear indicator of a leak or significant outgassing.

Perform Leak Detection

If you suspect a leak, a formal leak detection process is necessary. This can be as simple as a "rate-of-rise" test (measuring how fast pressure increases when the pump is valved off) or as sophisticated as using a dedicated helium leak detector to pinpoint the exact location of the leak.

Practice Vacuum Hygiene

For high-performance systems, cleanliness is non-negotiable. Always use powder-free gloves when handling internal components to avoid transferring skin oils. Clean parts with appropriate lint-free wipes and solvents (like isopropyl alcohol) to remove contaminants that would otherwise become a major outgassing load.

Understanding the Trade-offs

Every decision in vacuum system design involves balancing performance, cost, and convenience.

Cost vs. Performance

A system built with all-metal seals and specialized materials will have extremely low outgassing and can reach very low pressures. However, it is significantly more expensive and less forgiving than a system using common elastomer O-rings, which are cheaper but have higher outgassing and permeation rates.

Pump Complexity vs. Pressure Level

Achieving rough vacuum (e.g., for mechanical holding) can be done with a simple, robust mechanical pump. Reaching high vacuum requires a more complex and sensitive system, often involving a second-stage pump (like a turbomolecular or diffusion pump) that cannot be exposed to atmospheric pressure.

Bakeout Procedures: Effort vs. Purity

In high-vacuum applications, baking out the system (heating the chamber to 150-400°C while pumping) is a common practice. The heat provides the energy needed for adsorbed molecules like water to release from the surfaces, dramatically reducing outgassing and enabling lower ultimate pressures. This adds time and complexity to the process but is often essential.

Making the Right Choice for Your Goal

Your strategy for maintaining pressure depends entirely on your application's requirements.

- If your primary focus is rough vacuum (e.g., filtration, vacuum chucks): Ensure all fittings are tight, use thick-walled vacuum tubing that won't collapse, and verify your pump oil is clean and at the correct level.

- If your primary focus is high vacuum (e.g., coatings, mass spectrometry): You must prioritize clean, low-outgassing materials, minimize elastomer seals, perform regular leak checks, and consider implementing bakeout procedures.

Ultimately, maintaining vacuum pressure is an active process of managing the equilibrium between what you remove and what you allow to remain.

Summary Table:

| Key Factor | Description | Common Solutions |

|---|---|---|

| Leaks | Physical pathways for gas entry | Check O-rings, welds, and fittings; perform leak detection tests |

| Outgassing | Release of trapped gases from materials | Use low-outgassing materials (e.g., stainless steel); practice vacuum hygiene |

| Permeation | Gas diffusion through solid barriers | Minimize elastomer seals; use metal seals for ultra-high vacuum |

| Pump Selection | Matches gas load and target pressure | Choose pumps with adequate speed (e.g., turbomolecular for high vacuum) |

Struggling with unstable vacuum pressure in your lab? KINTEK specializes in lab equipment and consumables, providing reliable vacuum solutions tailored to your needs—from rough vacuum for filtration to high-vacuum systems for coatings and spectrometry. Our experts help you select the right pumps, materials, and maintenance practices to achieve lasting performance. Contact us today to optimize your vacuum system and enhance your lab's efficiency!

Visual Guide

Related Products

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- What are the disadvantages of nitriding? Key Limitations of Each Process Method

- What is the purpose of using a vacuum pump system for magnesium thermic reduction? Ensure High-Purity Titanium Production

- How do high-precision laboratory furnaces ensure the validity of experiments in nuclear simulation? ±1 K Stability

- Why is a vacuum drying oven required for epoxy curing agents? Prevent Bubbles & Ensure Chemical Purity

- What is the application of quenching effect? Achieve Superior Hardness and Strength in Materials

- Why is a vacuum drying oven required for the surface modification of aramid fibers? Eliminate Voids & Boost Adhesion.

- At what temperature does annealing take place? A Guide to Material-Specific Heat Treatment

- What are the uses of vacuum furnace? Achieve Unmatched Material Purity and Performance