At its core, a diamond-like carbon (DLC) coating works by creating a thin film of amorphous carbon on a component's surface. This film is not pure diamond or pure graphite, but a unique hybrid. It contains a mixture of incredibly hard, diamond-type atomic bonds (called sp3) and slick, graphite-type atomic bonds (called sp2), which combine to deliver exceptional hardness and low friction simultaneously.

The essential principle behind DLC is atomic-level engineering. By controlling the ratio of diamond (hard) to graphite (lubricating) bonds during the deposition process, manufacturers can fine-tune the coating's properties to meet specific performance goals, from extreme wear resistance to ultra-low friction.

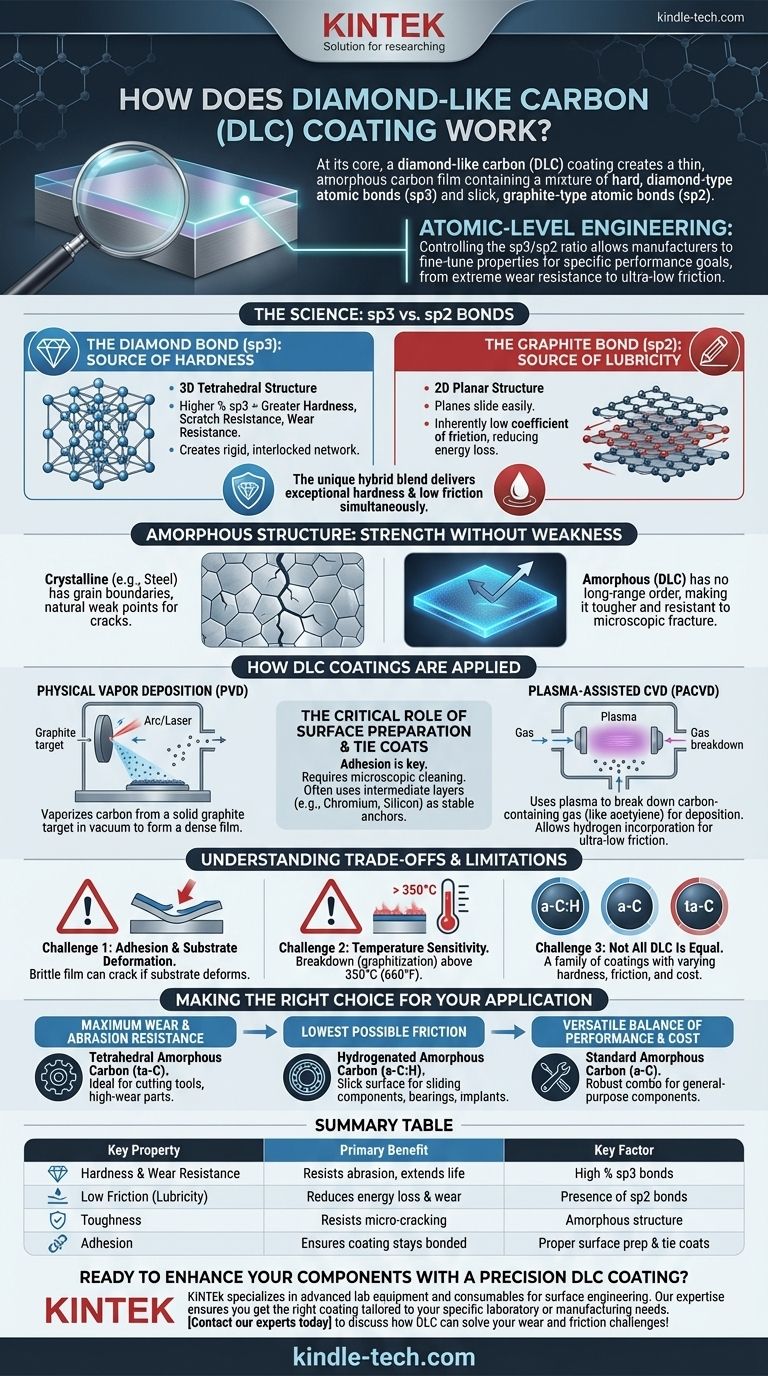

The Science Behind the Properties: sp3 vs. sp2 Bonds

The unique capabilities of DLC are not magic; they are a direct result of the specific ways carbon atoms bond to each other within the film.

The Diamond Bond (sp3): The Source of Hardness

The sp3 bond is the three-dimensional tetrahedral structure that gives natural diamond its legendary hardness. Within a DLC film, a higher percentage of these sp3 bonds directly translates to greater hardness, scratch resistance, and wear resistance.

This structure creates a rigid, interlocked atomic network that strongly resists being deformed or penetrated.

The Graphite Bond (sp2): The Source of Lubricity

The sp2 bond is the two-dimensional planar structure found in graphite. These planes can slide over one another with very little force, which is what makes graphite an excellent solid lubricant.

The presence of sp2 bonds within the DLC matrix is responsible for the coating's inherently low coefficient of friction, reducing the energy needed for parts to slide against each other.

Amorphous Structure: Strength Without Weakness

Unlike crystalline materials like diamond or steel, DLC is amorphous, meaning its atoms have no long-range, ordered pattern. This is a significant advantage.

Crystalline materials have grain boundaries, which act as natural weak points where cracks can start and propagate. The lack of these boundaries in an amorphous DLC film makes it tougher and more resistant to fracture on a microscopic level.

How DLC Coatings Are Applied

Applying a film that is only a few microns thick requires highly specialized processes conducted in a vacuum.

Physical Vapor Deposition (PVD)

In PVD, a high-energy process (like an arc or a laser) strikes a solid graphite target inside a vacuum chamber. This vaporizes carbon atoms, which then travel and condense onto the component, forming the dense DLC film.

Plasma-Assisted Chemical Vapor Deposition (PACVD)

In PACVD, a carbon-containing gas (such as acetylene) is introduced into the chamber. A plasma is then generated, which breaks down the gas molecules and energizes the carbon atoms, causing them to deposit onto the part's surface. This method allows for the incorporation of hydrogen, creating specific types of DLC with extremely low friction.

The Critical Role of Surface Preparation

The performance of any DLC coating is entirely dependent on its ability to adhere to the substrate. Before coating, the component must be perfectly cleaned on a microscopic level.

Often, one or more thin intermediate layers (e.g., chromium or silicon) are deposited first. These "tie coats" act as a stable anchor between the component's base material and the final DLC film.

Understanding the Trade-offs and Limitations

While powerful, DLC is not a universal solution. Understanding its limitations is key to successful implementation.

Challenge 1: Adhesion and Substrate Deformation

A DLC film is only as good as its bond to the part. If surface preparation is poor, the coating can flake or peel off under stress.

Furthermore, the coating is a very thin, hard shell. If the underlying material is soft and deforms significantly under load, the brittle DLC layer can crack because it cannot stretch with the base material.

Challenge 2: Temperature Sensitivity

Most DLC coatings begin to break down and convert to softer graphite (a process called graphitization) at temperatures above 350°C (660°F). This limits their use in certain high-temperature engine or exhaust components.

Challenge 3: Not All DLC Is Created Equal

The term "DLC" refers to a family of coatings, not a single material. Different types include hydrogenated (a-C:H), non-hydrogenated (a-C), and tetrahedral amorphous carbon (ta-C). They vary significantly in hardness, friction, and cost. Specifying "DLC" without further detail is insufficient for a technical application.

Making the Right Choice for Your Application

Selecting the correct coating requires matching its properties to your primary engineering goal.

- If your primary focus is maximum wear and abrasion resistance: You need a coating with the highest possible sp3 content, such as tetrahedral amorphous carbon (ta-C), which is ideal for cutting tools and high-wear mechanical parts.

- If your primary focus is the lowest possible friction: Choose a hydrogenated amorphous carbon coating (a-C:H), as the hydrogen helps create a super-slick surface perfect for sliding engine components, bearings, and medical implants.

- If your primary focus is a versatile balance of performance and cost: Standard amorphous carbon (a-C) applied via PVD or PACVD offers a robust combination of hardness and lubricity suitable for a wide range of general-purpose components.

By understanding this interplay of atomic structure and material properties, you can specify a DLC coating that delivers a precise, predictable performance advantage.

Summary Table:

| Key Property | Primary Benefit | Key Factor |

|---|---|---|

| Hardness & Wear Resistance | Resists abrasion and extends component life | High percentage of sp3 (diamond) bonds |

| Low Friction (Lubricity) | Reduces energy loss and wear | Presence of sp2 (graphite-like) bonds |

| Toughness | Resists micro-cracking and fracture | Amorphous (non-crystalline) structure |

| Adhesion | Ensures coating stays bonded under stress | Proper surface preparation and tie coats |

Ready to enhance your components with a precision DLC coating? KINTEK specializes in advanced lab equipment and consumables for surface engineering. Our expertise ensures you get the right coating—whether for maximum hardness, ultra-low friction, or a balanced performance—tailored to your specific laboratory or manufacturing needs. Contact our experts today to discuss how DLC can solve your wear and friction challenges!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are the synthesis methods for graphene? A Guide to Top-Down vs. Bottom-Up Production

- Can SiO2 be sputtered? RF vs. Reactive Sputtering for Superior SiO2 Films

- What are the different types of single-walled carbon nanotubes? Armchair, Zigzag, and Chiral Structures Explained

- What are the applications of thin films in nanotechnology? Powering Electronics, Energy, and Advanced Materials

- What are the different types of exfoliation for graphene? Choose the Right Method for Your Application

- How do I choose an ALD precursor? Select the Right Chemical for Superior Thin Films

- What is the need of coating for wear resistance? Extend Component Life and Reduce Costs

- What method is used to make thin films? A Guide to Chemical and Physical Deposition