At its core, electron beam processing is a highly precise manufacturing method that uses a focused beam of high-velocity electrons to modify materials inside a vacuum. This beam acts as a powerful energy source, converting the kinetic energy of the electrons into intense, localized heat upon impact. This heat can either vaporize a source material to create a thin coating on a substrate or vaporize the workpiece itself for cutting and drilling.

The essential principle of electron beam technology is the precise control of immense energy. By directing a stream of electrons, you can either add material atom-by-atom to build a surface (deposition) or subtract material with surgical precision to cut it (machining).

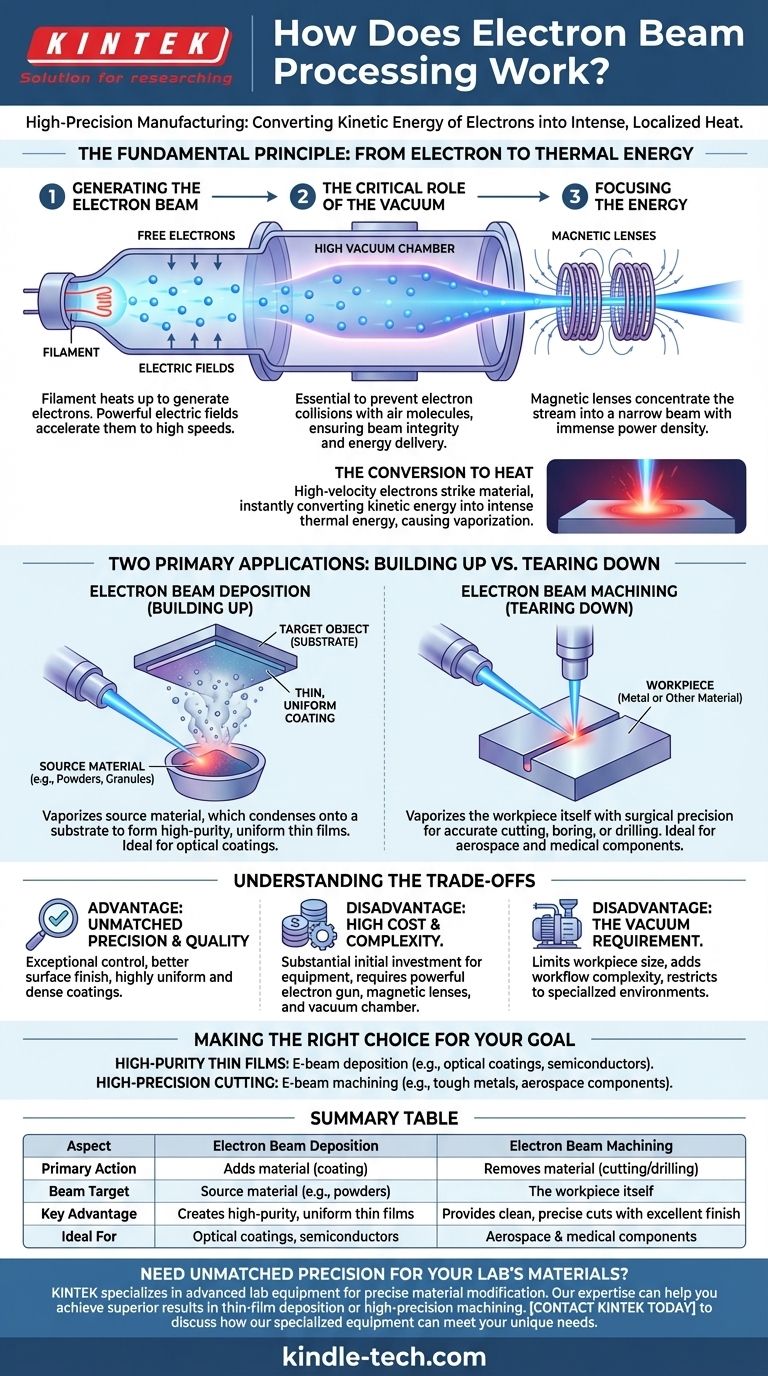

The Fundamental Principle: From Electron to Thermal Energy

To understand how electron beam processing works, it's crucial to grasp the three key stages: generation, focusing, and impact. These principles are consistent across all its applications.

Generating the Electron Beam

The process begins by generating free electrons, typically by heating a filament. These electrons are then accelerated to very high speeds using powerful electric fields, creating a stream of high-energy particles.

The Critical Role of the Vacuum

The entire process must occur in a high-vacuum chamber. This is non-negotiable because the electrons would otherwise collide with air molecules, scattering the beam and losing their energy before reaching the target.

Focusing the Energy

Magnetic lenses are used to focus this stream of electrons into an incredibly narrow beam. This concentration is what creates a very high power density, allowing for the precise delivery of energy to a microscopic spot on the target material.

The Conversion to Heat

When the high-velocity electrons strike the material, their kinetic energy is instantly converted into thermal energy. This energy transfer is so rapid and intense that it causes the target material to heat up and vaporize almost instantaneously.

Two Primary Applications: Building Up vs. Tearing Down

The same fundamental principle of electron-to-heat conversion is applied in two opposite ways: to add material or to remove it.

Electron Beam Deposition (Building Up)

In deposition, the electron beam is aimed at a source material, such as powders or granules, held in a container. The beam's energy vaporizes this source material. This vapor then travels through the vacuum chamber and condenses onto a target object (the substrate), forming an extremely thin, uniform, and high-purity coating. This method is common for creating advanced optical coatings.

Electron Beam Machining (Tearing Down)

In machining, the electron beam is aimed directly at the workpiece itself. The intense, focused heat vaporizes the material in a precise path. By controlling the beam's movement, this process can be used to accurately cut, bore, or drill through a wide variety of metals with minimal thermal damage to the surrounding area.

Understanding the Trade-offs

Like any advanced technology, electron beam processing has distinct advantages and limitations that define its ideal use cases.

Advantage: Unmatched Precision and Quality

The process offers exceptional control. For machining, it results in a better surface finish and a narrower cut than most other thermal cutting methods. For deposition, it allows for the creation of highly uniform, dense, and robust coatings.

Disadvantage: High Cost and Complexity

The primary barrier to wider adoption is the high cost of the equipment. The need for a powerful electron gun, magnetic focusing lenses, and a high-vacuum chamber makes the initial investment substantial.

Disadvantage: The Vacuum Requirement

The necessity of a vacuum chamber limits the size of the workpiece and adds complexity to the manufacturing workflow. This is not a process that can be performed in an open-air environment, restricting it to specialized, high-value applications.

Making the Right Choice for Your Goal

Deciding whether to use electron beam technology depends entirely on the required level of precision and the value of the final product.

- If your primary focus is creating high-purity, uniform thin films: E-beam deposition offers superior control for advanced applications like precision optical coatings and semiconductor manufacturing.

- If your primary focus is high-precision cutting of tough metals: E-beam machining provides a clean, accurate cut with an excellent surface finish, making it ideal for high-value components in the aerospace and medical industries.

Ultimately, electron beam processing provides an unparalleled level of energy control for manipulating materials at the microscopic level.

Summary Table:

| Aspect | Electron Beam Deposition | Electron Beam Machining |

|---|---|---|

| Primary Action | Adds material (coating) | Removes material (cutting/drilling) |

| Beam Target | Source material (e.g., powders) | The workpiece itself |

| Key Advantage | Creates high-purity, uniform thin films | Provides clean, precise cuts with excellent finish |

| Ideal For | Optical coatings, semiconductors | Aerospace & medical components |

Need Unmatched Precision for Your Lab's Materials?

Electron beam processing delivers the microscopic control required for high-value applications. KINTEK specializes in advanced lab equipment, including solutions for precise material modification. Our expertise can help you achieve superior results in thin-film deposition or high-precision machining.

Contact KINTEK today to discuss how our specialized equipment and consumables can meet your laboratory's unique needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- Does tensile strength increase with heat treatment? How to Engineer the Perfect Metal Properties

- What is the temperature of a sintering furnace? Unlock the Key to Perfect Material Densification

- What is the temperature of a pyrolysis reactor? Master Thermal Control for Optimal Product Yields

- What is sinter metal? A Guide to Cost-Effective, Complex Metal Parts

- What are the advantages of sintering? Achieve Superior Material Properties and Cost-Effective Production

- Why is the control of moisture evaporation critical in the Cu-Cl cycle? Optimize Particle Quality & Reactivity

- How is in-situ Raman spectroscopy utilized to evaluate the stability of anti-corrosion coatings? Precision Real-Time Monitoring

- What is the unit of coating thickness? Avoid Costly Errors with Microns vs. Mils