In short, sample size is the single most important factor determining the reliability and precision of your analytical results. A larger, properly selected sample size increases your confidence that the findings are not due to random chance, providing a more accurate representation of the true state of the underlying population you are studying.

The core takeaway is that sample size isn't just about collecting more data; it's a strategic decision that directly controls two critical factors: your ability to detect a real effect (statistical power) and the certainty of your measurements (precision).

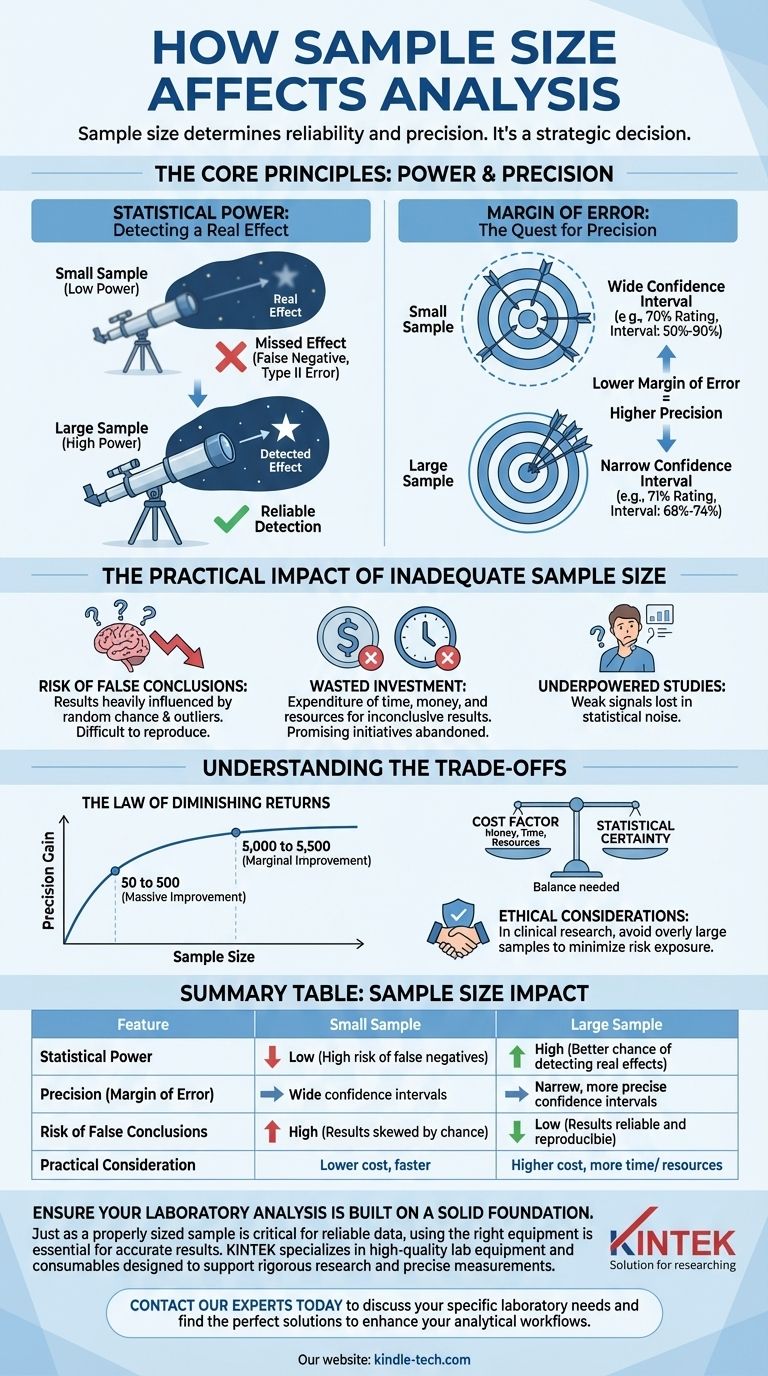

The Core Principles: Power and Precision

To understand the impact of sample size, you must grasp the two fundamental concepts it governs. These principles explain why "more is often better" in data analysis.

Statistical Power: The Ability to Detect an Effect

Statistical power is the probability that your study will detect an effect that truly exists. It's like having a powerful enough telescope to see a distant star.

A small sample size is a low-power telescope. Even if a real, important effect is present (a breakthrough drug's benefit, a successful marketing campaign), an underpowered study is likely to miss it entirely.

This leads to a Type II error, or a false negative. You mistakenly conclude there is no effect when, in fact, there is one.

Margin of Error: The Quest for Precision

Margin of error describes the precision of your findings. It creates a confidence interval, which is a range you can be reasonably sure contains the true value for the entire population.

With a small sample, your margin of error is large. You might find that a new product has a satisfaction rating of 70%, but your confidence interval is 50% to 90%. This range is too wide to be useful for making a business decision.

As your sample size increases, the margin of error shrinks. A larger sample might give you a rating of 71% with a much tighter confidence interval of 68% to 74%. This is a precise and actionable insight.

The Practical Impact of Inadequate Sample Size

Choosing a sample size that is too small is one of the most common analytical mistakes. It undermines your work and can lead to costly errors in judgment.

Risk of False Conclusions

The primary danger of a small sample is that your results are heavily influenced by random chance and outliers. You might observe a strong pattern that completely disappears when more data is collected.

This makes your findings difficult to reproduce, which is a cornerstone of credible research and analysis.

Wasted Investment in Research

An underpowered study is often a wasted investment. You expend time, money, and resources only to arrive at an inconclusive result.

Worse, a false negative might cause you to abandon a promising initiative, product, or line of research because the weak signal was lost in the statistical noise.

Understanding the Trade-offs

While a larger sample size is statistically superior, practical constraints always play a role. The goal is not to collect the maximum amount of data possible, but the optimal amount.

The Law of Diminishing Returns

The statistical benefit you gain from increasing your sample size is not linear. The improvement from 50 to 500 participants is massive. The improvement from 5,000 to 5,500 is marginal.

At a certain point, the cost of collecting more data outweighs the small gain in precision you will achieve.

The Cost Factor: Time and Resources

Data collection is often the most expensive and time-consuming part of a project. Every data point has a cost in terms of money, labor, and computing power.

You must balance the need for statistical certainty with the budget and timeline of your project.

Ethical Considerations

In fields like clinical research, using an overly large sample can be unethical. It may expose more participants than necessary to potential risks or deny a control group access to a superior treatment for longer than required.

Making the Right Choice for Your Goal

Your optimal sample size depends entirely on the objective of your analysis. A formal "power analysis" is the standard method for calculating this, but a conceptual understanding will guide your strategy.

- If your primary focus is early-stage exploratory research: A smaller, more flexible sample may be acceptable to identify potential signals or test a hypothesis directionally, with the full understanding that the results are not definitive.

- If your primary focus is high-stakes decision-making (e.g., a clinical trial or a multi-million dollar investment): A larger, statistically significant sample is non-negotiable. The cost of being wrong is far too high to risk an underpowered study.

- If your primary focus is understanding a population (e.g., a national political poll): Your priority is a low margin of error. A sufficient sample size is required to ensure the precision of your estimates reflects the true population accurately.

Properly sizing your sample isn't just a statistical formality; it is the foundation upon which every credible conclusion is built.

Summary Table:

| Sample Size Impact | Small Sample | Large Sample |

|---|---|---|

| Statistical Power | Low (High risk of false negatives) | High (Better chance of detecting real effects) |

| Precision (Margin of Error) | Wide confidence intervals | Narrow, more precise confidence intervals |

| Risk of False Conclusions | High (Results easily skewed by chance) | Low (Results are more reliable and reproducible) |

| Practical Consideration | Lower cost, faster | Higher cost, more time/resources |

Ensure your laboratory analysis is built on a solid foundation.

Just as a properly sized sample is critical for reliable data, using the right equipment is essential for accurate results. KINTEK specializes in high-quality lab equipment and consumables designed to support rigorous research and precise measurements.

Let us help you achieve confidence in your data. Contact our experts today to discuss your specific laboratory needs and find the perfect solutions to enhance your analytical workflows.

Visual Guide

Related Products

- XRD Sample Holder X-ray Diffractometer Powder Slide

- Lab Vibration Mill

- Electrode Polishing Material for Electrochemical Experiments

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is a slow pyrolysis? A Guide to Maximizing Biochar Production from Biomass

- How does a hot air furnace work? Understanding Safe and Efficient Home Heating

- How mechanical properties are affected by sintering? Master the Trade-offs for Stronger Materials

- What is titanium disadvantages and advantages? Weighing Performance vs. Cost for Your Project

- How does a precision centrifuge contribute to electrochemical wastewater analysis? Ensure Data Integrity and Accuracy

- What is the delta 20 rule? A Guide to Diagnosing and Perfecting Your Espresso

- Which metal is harder to melt? Tungsten Leads with the Highest Melting Point

- What are the principles of thin film? A Guide to Engineered Materials & Deposition Techniques