In the process of sieving, size is the absolute determining factor. The entire method is a mechanical test of geometry: a particle is presented to a fixed opening, or aperture, in a sieve mesh. If the particle's dimensions are smaller than the aperture, it passes through; if it is larger, it is retained on the sieve surface. Agitation ensures each particle has an opportunity to encounter an aperture, but the final separation is based purely on this dimensional comparison.

The core principle is that sieving establishes a precise physical barrier—the sieve mesh—to sort particles. Effective separation depends entirely on the geometric relationship between a particle's size and shape versus the fixed size of the sieve's openings.

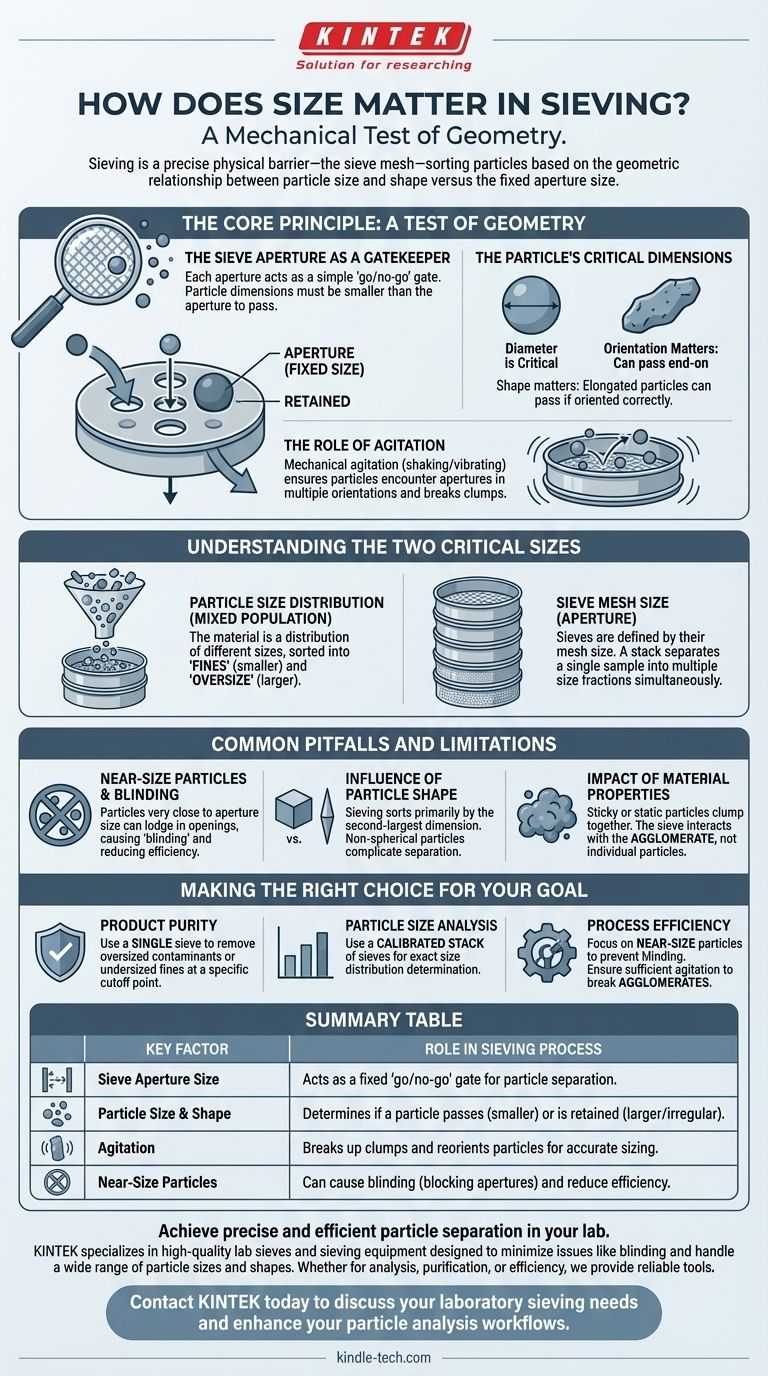

The Core Principle: A Test of Geometry

Sieving is one of the oldest and most intuitive methods of particle separation. Its effectiveness relies on a few fundamental interactions between the material and the equipment.

The Sieve Aperture as a Gatekeeper

The openings in the sieve mesh, known as apertures, are the heart of the process. These apertures are manufactured to a highly consistent and specific size.

Each aperture acts as a simple "go/no-go" gate. The size of this gate is the single reference point against which all particles in the sample are measured.

The Particle's Critical Dimensions

For a particle to pass through the sieve, its dimensions must be smaller than the aperture. This seems simple, but particle shape plays a significant role.

A spherical particle has one critical dimension: its diameter. However, an elongated or irregular particle may pass through if it approaches the aperture in the correct orientation (e.g., end-on), even if its longest dimension is greater than the aperture size.

The Role of Agitation

A static pile of material will not sieve itself. Mechanical agitation—shaking or vibrating the sieve—is essential.

Agitation serves two purposes. First, it breaks up clumps and ensures individual particles move independently. Second, it continually reorients the particles, giving them multiple chances to present their smallest dimension to an aperture and pass through.

Understanding the Two Critical Sizes

Effective sieving is not about one size, but the relationship between two: the size of the particles you are sorting and the size of the holes in the screen you are using.

Particle Size

The material being sieved is never perfectly uniform. It is a distribution of different particle sizes.

The goal of sieving is to take this mixed distribution and separate it into two populations: particles smaller than the aperture (the "fines") and particles larger than the aperture (the "oversize").

Sieve Mesh Size (Aperture)

Sieves are defined by their mesh size, which corresponds to a specific aperture dimension. For precise analysis, a stack of sieves is often used.

By arranging sieves in a stack from the largest aperture on top to the smallest on the bottom, a single sample can be separated into multiple size fractions simultaneously.

Common Pitfalls and Limitations

While the principle is simple, several factors related to size and shape can complicate the process and lead to inaccurate results.

The Problem of "Near-Size" Particles

Particles that are very close in size to the sieve aperture are the most difficult to sort.

These near-size particles can become lodged in the apertures, blocking them and preventing other, smaller particles from passing through. This phenomenon is known as blinding and significantly reduces the efficiency of the sieve.

The Influence of Particle Shape

As mentioned, non-spherical particles complicate separation. A long, needle-like particle might be retained, while a cube-shaped particle with the same mass might pass easily.

This means that sieving sorts particles primarily by their second-largest dimension, not necessarily by their volume or mass.

The Impact of Material Properties

If particles are sticky or prone to static electricity, they can clump together.

When this happens, the sieve interacts with the size of the agglomerate, not the individual particles. This leads to fine particles being incorrectly retained on the sieve surface as part of a larger clump.

Making the Right Choice for Your Goal

To apply these principles correctly, you must first define your objective. The ideal approach depends entirely on what you are trying to achieve with your material.

- If your primary focus is product purity: Use a single sieve with an aperture size set at your specific cutoff point to remove either oversized contaminants or undersized fines.

- If your primary focus is particle size analysis: Use a calibrated stack of sieves with progressively smaller apertures to determine the exact size distribution within your sample.

- If your primary focus is process efficiency: Pay close attention to near-size particles that can cause blinding and ensure your agitation method is sufficient to break up any agglomerates.

Ultimately, mastering sieving is about controlling the geometric interaction between your material and your mesh.

Summary Table:

| Key Factor | Role in Sieving Process |

|---|---|

| Sieve Aperture Size | Acts as a fixed 'go/no-go' gate for particle separation. |

| Particle Size & Shape | Determines if a particle passes (smaller) or is retained (larger/irregular). |

| Agitation | Breaks up clumps and reorients particles for accurate sizing. |

| Near-Size Particles | Can cause blinding (blocking apertures) and reduce efficiency. |

Achieve precise and efficient particle separation in your lab.

The principles of sieving are fundamental, but the right equipment is key to accurate results. KINTEK specializes in high-quality lab sieves and sieving equipment designed to minimize issues like blinding and handle a wide range of particle sizes and shapes.

Whether your goal is rigorous particle size analysis, product purification, or improving process efficiency, we provide the reliable tools you need. Let our experts help you select the ideal sieves for your specific materials and applications.

Contact KINTEK today to discuss your laboratory sieving needs and enhance your particle analysis workflows.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy