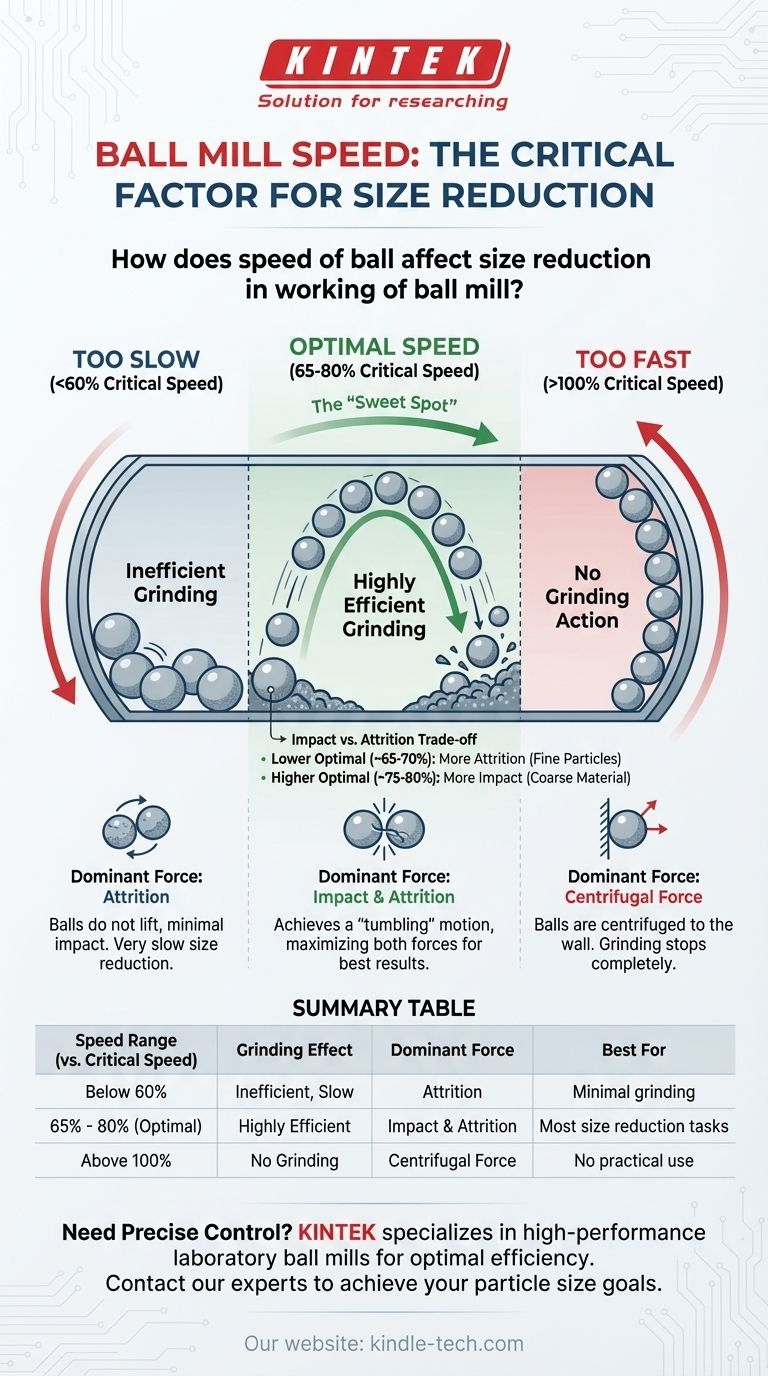

In a ball mill, speed is the most critical parameter for size reduction, but the relationship is not linear. Instead of "faster is better," an optimal speed exists to maximize the grinding effect. Operating a mill too slowly results in minimal size reduction, while operating it too quickly causes grinding to stop altogether as the balls are pinned to the cylinder wall.

The core principle is that effective size reduction depends on achieving a "tumbling" motion that maximizes impact and frictional forces. This ideal state occurs at a specific percentage of the mill's "critical speed"—the point where centrifugal force overcomes gravity.

The Mechanics of Grinding Forces

To control size reduction, you must first understand the two primary forces at play inside the mill. The mill's speed directly dictates which of these forces will dominate the process.

Impact Forces

Impact is the primary force for breaking down larger, coarse particles. It occurs when the grinding balls are lifted high along the side of the rotating drum and then fall, or "cascade," onto the material below, acting like thousands of tiny hammers.

Attrition Forces

Attrition, or friction, is a shearing force that is most effective for grinding material into very fine particles. This occurs when balls slide and roll against each other and the mill liner, grinding the material caught between them.

The Concept of Critical Speed

The effectiveness of these forces is entirely governed by the mill's rotational speed, which is best understood in relation to its theoretical "critical speed."

What is Critical Speed?

Critical speed is the theoretical RPM at which the centrifugal force inside the mill exactly balances the force of gravity. At this speed, the grinding balls are pinned against the inner wall of the drum and rotate with it, creating no tumbling, no impact, and therefore, no grinding.

Below Optimal Speed (Too Slow)

If the mill rotates too slowly (e.g., below 60% of critical speed), the balls are not lifted high enough. They simply roll over one another at the bottom of the mill. This generates some attrition but creates almost no impact, leading to a very slow and inefficient grinding process, especially for larger particles.

At Optimal Speed (The "Sweet Spot")

Most ball mills are operated between 65% and 80% of their critical speed. In this range, the balls are carried high enough up the wall to create a continuous, rolling "cascade" back into the material charge. This motion provides the ideal combination of both impact and attrition, leading to the most efficient and effective size reduction.

Above Optimal Speed (Too Fast)

As the speed approaches and exceeds the critical speed, centrifugal force takes over completely. The balls become "centrifuged" and are held fast against the drum liner. With no relative movement between the balls, all grinding action ceases.

Understanding the Trade-offs

Choosing a speed even within the optimal range involves balancing competing goals. The exact percentage you choose affects the final particle size, processing time, and operational cost.

Grinding Mode vs. Speed

The upper end of the optimal range (e.g., 75-80% of critical speed) favors a cascading motion, which increases impact forces. This is better for quickly breaking down coarse material.

The lower end of the optimal range (e.g., 65-70% of critical speed) favors a "cataracting" motion where balls roll more than they fall. This increases attrition forces, which is superior for achieving a very fine final particle size.

Efficiency vs. Wear

Higher speeds consume more energy and significantly increase the rate of wear on both the grinding media (the balls) and the mill's inner lining. Running a mill faster than necessary for your target particle size is inefficient and increases maintenance costs.

Setting the Right Speed for Your Goal

Your operational speed should be a deliberate choice based on your specific objective. Use the critical speed of your mill as the benchmark for all calculations.

- If your primary focus is rapidly breaking down coarse material: Operate toward the higher end of the optimal range (~75-80% of critical speed) to maximize impact.

- If your primary focus is producing extremely fine, uniform particles: Operate toward the lower end of the optimal range (~65-70% of critical speed) to maximize attrition.

- If your primary focus is balanced efficiency and throughput: Start at approximately 75% of critical speed and adjust based on the results for your specific material.

By mastering the relationship between speed and grinding forces, you gain precise control over the particle size reduction process.

Summary Table:

| Speed Range (vs. Critical Speed) | Grinding Effect | Dominant Force | Best For |

|---|---|---|---|

| Below 60% | Inefficient, Slow | Attrition | Minimal grinding |

| 65% - 80% (Optimal) | Highly Efficient | Impact & Attrition | Most size reduction tasks |

| Above 100% | No Grinding | Centrifugal Force | No practical use |

Need precise control over your particle size reduction? KINTEK specializes in high-performance laboratory ball mills and grinding equipment designed for optimal efficiency. Our experts can help you select the right mill and operational parameters to achieve your specific particle size goals, saving you time and reducing operational costs. Contact our grinding specialists today to discuss your application!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- How does a high-energy planetary ball mill facilitate the synthesis of sulfide glassy electrolytes? Achieve Amorphization

- Why is a laboratory ball mill used in Co-Ni catalyst research? Optimize CO2 Conversion with Precise Milling

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis