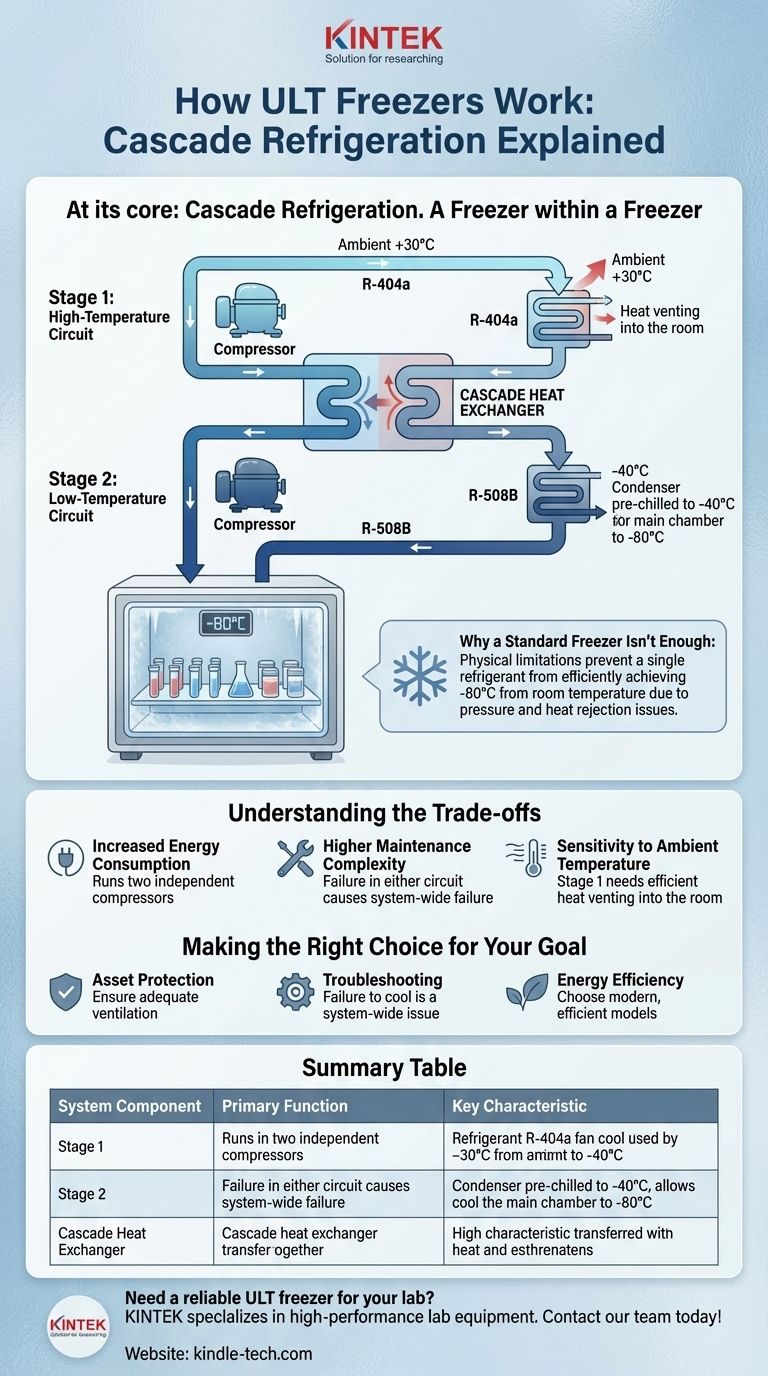

At its core, an ultra-low temperature (ULT) freezer works by using two refrigeration systems in a sequence, a process known as cascade refrigeration. Unlike a standard household freezer that uses a single cooling loop, a ULT freezer uses a primary refrigeration circuit to cool a secondary circuit. This two-stage approach allows the secondary circuit to start from a much colder point, enabling it to reach extreme temperatures of -80°C or lower.

The critical concept to understand is that a ULT freezer is essentially a "freezer within a freezer." The first system removes heat from the second, and the second system removes heat from the interior chamber, allowing it to achieve temperatures far beyond the capability of any single refrigerant.

Why a Standard Freezer Isn't Enough

To understand the cascade system, we must first recognize the physical limitations of a single refrigeration cycle when aiming for such extreme temperatures.

The Limits of a Single Refrigerant

Every refrigerant has an optimal operating range of temperature and pressure. To absorb heat and get cold, a refrigerant must evaporate at a very low pressure.

At a target temperature like -80°C, the pressure required for a standard refrigerant would be so low it would approach a vacuum. Compressors are not designed to operate efficiently, or at all, in these vacuum conditions.

The Problem of Heat Rejection

For any refrigeration cycle to work, the compressed refrigerant must be able to release its heat to the surrounding environment (the room).

To do this, the refrigerant in the condenser coils must be significantly warmer than the ambient air. Achieving this massive temperature difference—from -80°C inside to over +30°C outside—in a single step is mechanically inefficient and practically impossible with common refrigerants.

The Cascade Refrigeration System Explained

The cascade system elegantly solves these problems by splitting the work into two interconnected stages, each with a specialized refrigerant.

Stage 1: The High-Temperature Circuit

The first stage functions much like a typical freezer. It uses a high-pressure refrigerant (like R-404a) to begin the cooling process.

However, its primary job is not to cool the freezer's main chamber. Instead, it absorbs heat from the second circuit, typically bringing it down to around -40°C.

Stage 2: The Low-Temperature Circuit

The second stage uses a specialized very-low-pressure refrigerant (like R-508B). The key is that its "environment" is not the room, but the -40°C environment created by Stage 1.

Because it starts from this pre-chilled state, this second circuit can easily operate at the extremely low pressures needed to evaporate and absorb heat from the main chamber, pulling its temperature down to the target of -80°C.

The Heat Exchanger: Where the Stages Meet

The two circuits are not physically mixed but are thermally connected by a critical component called a cascade heat exchanger.

Here, the evaporator coil of the first stage makes contact with the condenser coil of the second stage. Heat passes from the second circuit into the first, which then carries that heat out of the system and vents it into the room.

Understanding the Trade-offs

This two-stage design is highly effective, but it introduces complexity and requires careful management.

Increased Energy Consumption

Running two independent compressor systems consumes significantly more energy than a single-stage freezer. This is a direct trade-off for the ability to achieve and maintain extreme temperatures.

Higher Maintenance Complexity

A failure in either circuit will cause the entire system to fail. A leak or inefficiency in the high-temperature Stage 1 will prevent Stage 2 from getting cold enough, causing a cascading failure. This requires technicians with specialized knowledge of cascade systems.

Sensitivity to Ambient Temperature

The first stage must vent heat into the surrounding room. If the room is too hot or the freezer's vents are blocked, Stage 1 cannot cool efficiently. This directly impacts Stage 2's performance, making proper placement and ventilation absolutely critical.

Making the Right Choice for Your Goal

Understanding how the cascade system works allows you to operate and maintain these critical assets more effectively.

- If your primary focus is asset protection: Ensure the freezer has adequate ventilation space around it and is in a climate-controlled room to maximize the efficiency of the first cooling stage.

- If your primary focus is troubleshooting: Recognize that a failure to reach temperature is a system-wide problem; the issue could lie in the high-temperature circuit even if the low-temperature circuit appears to be the problem.

- If your primary focus is energy efficiency: Choose newer models that use more efficient compressors and environmentally friendly refrigerants, as the cascade design is inherently energy-intensive.

By viewing the ULT freezer as two coordinated systems, you can better appreciate its capabilities and its unique operational requirements.

Summary Table:

| System Component | Primary Function | Key Characteristic |

|---|---|---|

| Stage 1 (High-Temp Circuit) | Cools the second stage circuit | Uses a standard refrigerant (e.g., R-404a) to reach ~-40°C |

| Stage 2 (Low-Temp Circuit) | Cools the main storage chamber | Uses a specialized low-pressure refrigerant (e.g., R-508B) to reach -80°C or lower |

| Cascade Heat Exchanger | Transfers heat between the two stages | Allows Stage 1 to absorb heat from Stage 2's condenser |

Need a reliable ultra-low temperature freezer for your lab? KINTEK specializes in high-performance lab equipment, including ULT freezers that protect your most sensitive samples. Our experts can help you select the right model for your specific temperature, capacity, and energy efficiency requirements. Contact our team today to ensure your critical assets are stored safely and efficiently!

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- How should frost be removed from Ultra-Low Temperature Freezers? Protect Your Samples and Equipment

- What is convection-based cooling in ultra-low temperature freezers? Achieve Superior Temperature Stability for Your Samples

- Why are ultra-low temperature freezers important in scientific research? Ensure Sample Integrity and Reproducibility

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage