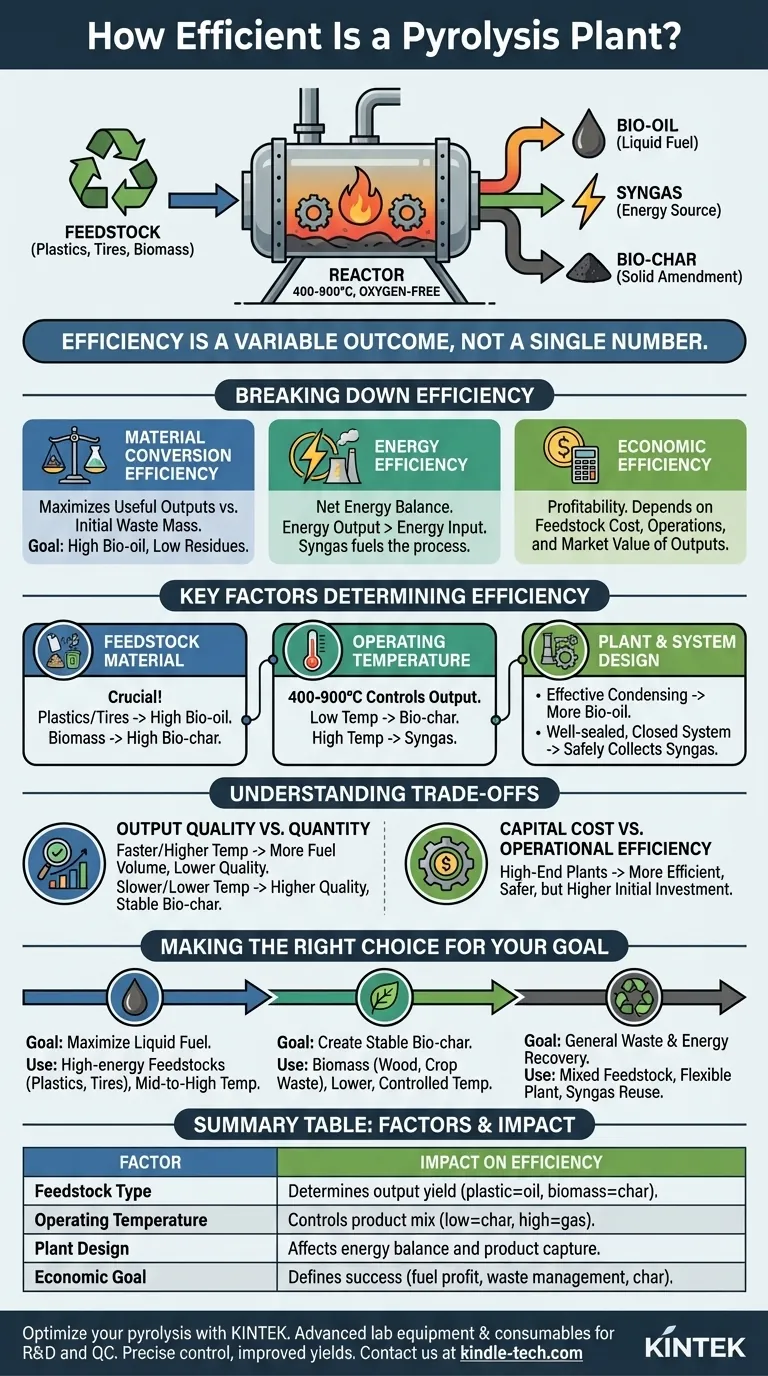

The efficiency of a pyrolysis plant is not a single, universal number. Instead, it is a variable outcome that depends heavily on the plant's design, the specific type of waste being processed (the feedstock), and its precise operating conditions. The core function is to convert materials like plastic, tires, or biomass into valuable outputs—bio-oil, syngas, and bio-char—by heating them in an oxygen-free environment.

The true measure of a pyrolysis plant's efficiency lies in its specific application. It is less about a universal percentage and more about how effectively a particular plant configuration converts a specific type of waste into its most valuable outputs, whether that be fuel, chemicals, or soil amendments.

What "Efficiency" Means in Pyrolysis

To understand a plant's performance, we must break down "efficiency" into three distinct categories.

Material Conversion Efficiency

This measures how much of the initial waste material (by mass) is successfully converted into useful products. The goal is to maximize the yield of desired outputs like bio-oil and minimize lower-value residues.

Energy Efficiency

This is the plant's net energy balance. A truly efficient plant produces more energy in its outputs than it consumes to heat the reactor and run the machinery. Many modern plants improve this balance by using the syngas they produce as fuel to power the process itself.

Economic Efficiency

This is the bottom line: is the operation profitable? This depends on the cost of acquiring and preparing the feedstock, operational expenses, and the market value of the bio-oil, char, and any surplus energy produced.

Key Factors That Determine Plant Efficiency

The performance of a pyrolysis plant is dictated by a few critical variables that can be fine-tuned to target specific outcomes.

The Feedstock Material

The type of waste used is the most significant factor. Plastics and old tires, for example, have high energy content and tend to yield a large percentage of liquid bio-oil. Woody biomass, on the other hand, typically produces a higher proportion of bio-char.

Operating Temperature

The temperature inside the reactor, typically ranging from 400-900°C, directly controls the composition of the output. Lower temperatures generally favor the production of solid bio-char, while higher temperatures "crack" the molecules further, yielding more syngas.

Plant and System Design

The engineering of the facility is crucial. A plant with a highly effective condensing unit, for example, will capture more of the valuable vapors as liquid bio-oil, significantly increasing product output. A well-sealed, closed-design system ensures that flammable syngas doesn't escape, allowing it to be safely collected for fuel.

Understanding the Trade-offs

Pursuing one type of efficiency can often create challenges in another area. Understanding these trade-offs is key to evaluating the technology objectively.

Output Quality vs. Quantity

Running the process faster and at higher temperatures might maximize the total volume of fuel produced, but its quality may be lower, requiring more costly refinement. Slower, lower-temperature processes often yield higher-quality, more stable bio-char.

Feedstock Purity

Pyrolysis works best with clean, relatively uniform feedstock. Contaminants like dirt, metals, or certain types of plastics can reduce the efficiency of the reaction, lower the quality of the outputs, and potentially damage the equipment.

Capital Cost vs. Operational Efficiency

Higher-end plants with advanced control systems and superior components are more efficient and safer to operate. However, their initial capital investment is significantly higher, which impacts the overall economic calculation.

Making the Right Choice for Your Goal

The "best" pyrolysis setup depends entirely on your primary objective.

- If your primary focus is maximizing liquid fuel production: You need a plant optimized to process high-energy feedstocks like plastics and tires, likely operating in the mid-to-high temperature range.

- If your primary focus is creating stable bio-char for agriculture: Your ideal setup will use biomass feedstock like wood or crop waste and operate at lower, more controlled temperatures.

- If your primary focus is general waste management with energy recovery: A flexible, robust plant that can handle mixed feedstock and efficiently reuse its own syngas for power is the most effective choice.

Ultimately, an efficient pyrolysis plant is one that is precisely engineered to match its intended feedstock and achieve its desired economic outcome.

Summary Table:

| Factor | Impact on Efficiency |

|---|---|

| Feedstock Type | Determines output yield (e.g., plastic for oil, biomass for char). |

| Operating Temperature | Controls product mix (low temp for char, high temp for gas). |

| Plant Design | Affects energy balance and product capture (e.g., condensing units). |

| Economic Goal | Defines success (fuel profit vs. waste management vs. char production). |

Ready to optimize your pyrolysis process for maximum efficiency and profitability? KINTEK specializes in advanced lab equipment and consumables for pyrolysis R&D and quality control. Whether you're testing feedstock, analyzing bio-oil, or scaling up production, our solutions help you achieve precise temperature control, improve product yields, and ensure operational safety. Contact our experts today to discuss how we can support your specific waste-to-energy goals!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Graphite Vacuum Continuous Graphitization Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- What conditions do laboratory high-pressure reactors provide for HTC? Optimize Your Biochar Production Processes

- Why are the design pressure and temperature ranges of high-pressure autoclaves critical for biomass HTL processes?

- What is the role of a high-temperature high-pressure autoclave in HTR simulation? Ensure Reactor Material Durability

- Why is a High-temperature and High-pressure Autoclave necessary for zirconium alloy testing? Ensure Nuclear Safety.

- What is the role of a stainless steel high-pressure reactor in the hydrothermal synthesis of MIL-88B? Boost MOF Quality