For optimal performance, a ball mill should be filled to 50% of its total volume with grinding media. This half-full level is the industry standard because it creates the ideal conditions for grinding. The remaining 50% of the space is essential, as it allows the media to be lifted by the mill's rotation and then cascade down, creating the impact and attrition forces that break down the material.

The 50% media fill level is not an arbitrary number; it is the calculated balance point. This level maximizes the grinding energy by providing the greatest possible drop height for the media while leaving sufficient room for the material being processed. Deviating significantly from this standard will directly compromise grinding efficiency and speed.

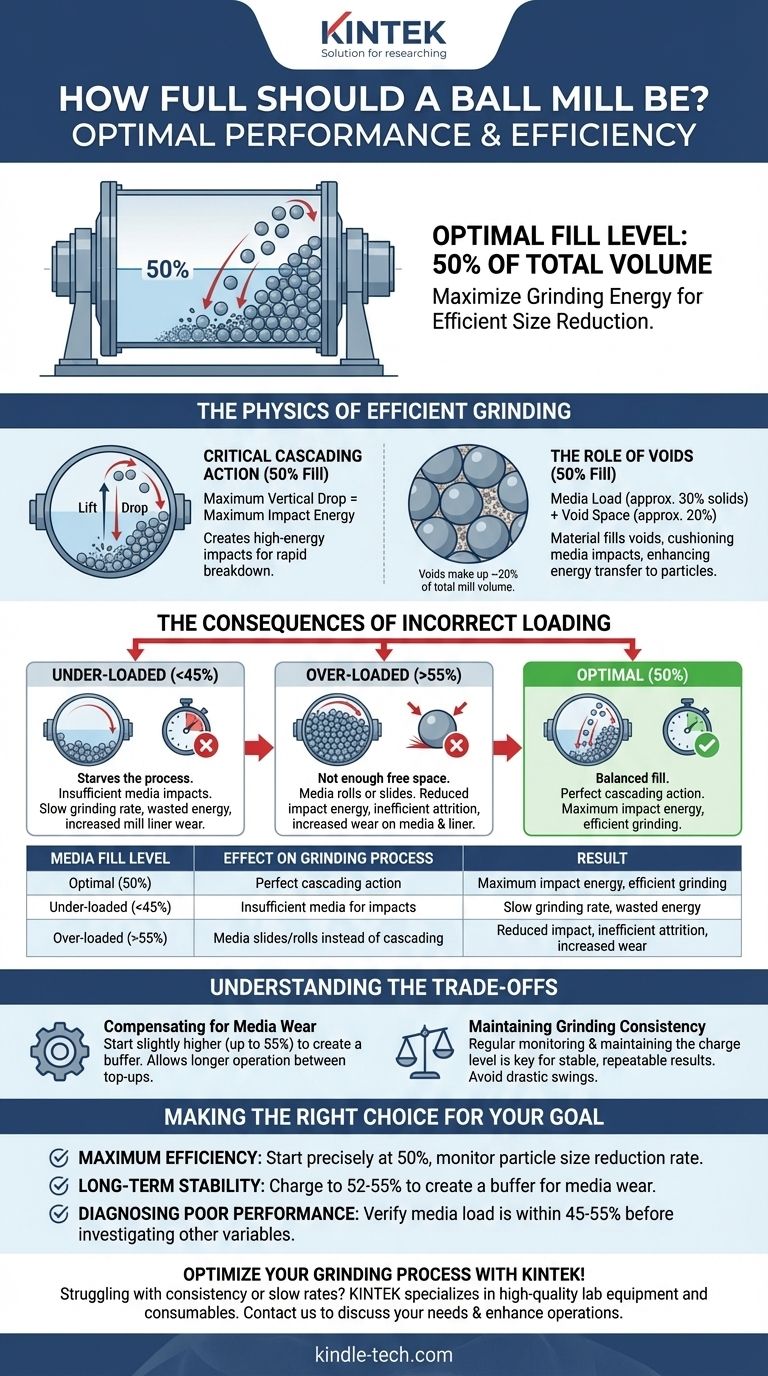

The Physics of Efficient Grinding

To understand why the fill level is so critical, you must first understand the mechanism by which a ball mill actually works. The goal is to create a controlled "cascading" or "cataracting" motion of the grinding media.

The Critical Cascading Action

Grinding is primarily achieved when the media (balls) are lifted up the side of the rotating drum and then fall back down onto the material below. This action creates high-energy impacts.

If the media is simply rolling or sliding at the bottom of the mill, you are only achieving slow, low-energy attrition (rubbing), which is highly inefficient. The 50% fill level provides the maximum vertical drop for the media, thus maximizing impact energy.

The Role of Voids and Material

When a mill is filled to 50% with media, the media itself does not occupy the full 50% of the space. The gaps between the individual balls, known as voids, typically make up about 20% of the mill's total volume.

This means a 50% media charge consists of roughly 30% solid media and 20% empty space. It is this void space that the material being ground should fill. The material effectively cushions the impacts between the media, ensuring energy is transferred to particle size reduction rather than being wasted on media-on-media or media-on-liner wear.

The Consequences of Incorrect Loading

Deviating from the 50% standard has immediate and predictable negative effects on your milling operation. Both under-loading and over-loading disrupt the crucial cascading action.

The Problem of Under-loading (<45%)

Filling the mill too low starves the process. There simply isn't enough grinding media to create the number of impacts needed for efficient size reduction.

This results in a slow grinding rate and wastes energy, as the mill motor is still doing the work to lift a sub-optimal media charge. It can also lead to excessive wear on the mill liner, as there isn't enough media and material to protect it from direct impacts.

The Problem of Over-loading (>55%)

Over-loading is a more common and often misunderstood mistake. When the mill is too full, there is not enough free space for the media to be lifted and fall.

Instead of cascading, the media charge tends to roll or slide over itself. This drastically reduces the impact energy, shifting the grinding action to inefficient attrition. The process slows down significantly, and you increase the rate of wear on both the media and the mill liner due to the constant rubbing motion.

Understanding the Trade-offs

While 50% is the ideal starting point, minor adjustments are sometimes made for practical, operational reasons.

Compensating for Media Wear

Grinding media wears down over time, reducing the total volume of the charge. To account for this, some operators start with a slightly higher charge, typically up to 55%.

This creates a buffer, allowing the mill to operate efficiently for longer periods before the media charge needs to be measured and topped up. Going beyond 55%, however, will begin to impede the cascading motion and reduce efficiency.

Maintaining Grinding Consistency

The most important factor is consistency. Drastic swings in the media load level will lead to unpredictable results in your final product.

Regularly monitoring and maintaining the media charge at your target level (whether it's precisely 50% or a 52-55% operational range) is key to a stable and repeatable grinding process.

Making the Right Choice for Your Goal

Your specific operational goal should guide your precise loading strategy.

- If your primary focus is maximum grinding efficiency: Start precisely at a 50% media load and monitor your particle size reduction rate to establish a performance baseline.

- If your primary focus is long-term operational stability: Charge to 52-55% to create a buffer that compensates for media wear, reducing the frequency of top-ups.

- If you are diagnosing poor performance: First, verify your media load is within the 45-55% range before investigating other variables like mill speed or material feed rate.

Achieving optimal grinding begins with establishing this fundamental balance within the mill.

Summary Table:

| Media Fill Level | Effect on Grinding Process | Result |

|---|---|---|

| Optimal (50%) | Perfect cascading action | Maximum impact energy, efficient grinding |

| Under-loaded (<45%) | Insufficient media for impacts | Slow grinding rate, wasted energy |

| Over-loaded (>55%) | Media slides/rolls instead of cascading | Reduced impact, inefficient attrition, increased wear |

Optimize your grinding process with KINTEK!

Struggling with inconsistent particle size or slow grinding rates? The right equipment and expert advice are crucial. KINTEK specializes in high-quality lab equipment and consumables, including ball mills and grinding media, designed to deliver precise and reliable results for your laboratory.

Let our experts help you achieve optimal performance and efficiency. Contact us today to discuss your specific needs and discover how our solutions can enhance your grinding operations.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the filling ratio for a ball mill? Optimize Grinding Efficiency & Particle Size

- What are the disadvantages of ball mill grinding? High Energy Use, Contamination, and Slow Processing

- What role does a planetary ball mill play in precursor mixing for Li3BO3? Enhance Your Material Homogeneity

- What is the primary role of a wet planetary ball mill? Optimize NaFePO4 (Maricite) Precursor Synthesis

- What is the function of a high-energy planetary ball mill? Unlock Nanoscale Precision in Powder Metallurgy

- How does the wet ball milling process facilitate the synthesis of modified solid-state Li4Ti5O12? Key Homogenization Steps

- What is the primary function of a planetary ball mill in Fe-Ni alloy prep? Master Mechanical Alloying Efficiency

- What is the core role of a high-energy planetary ball mill? Powering Sulfide Solid-State Electrolyte Synthesis