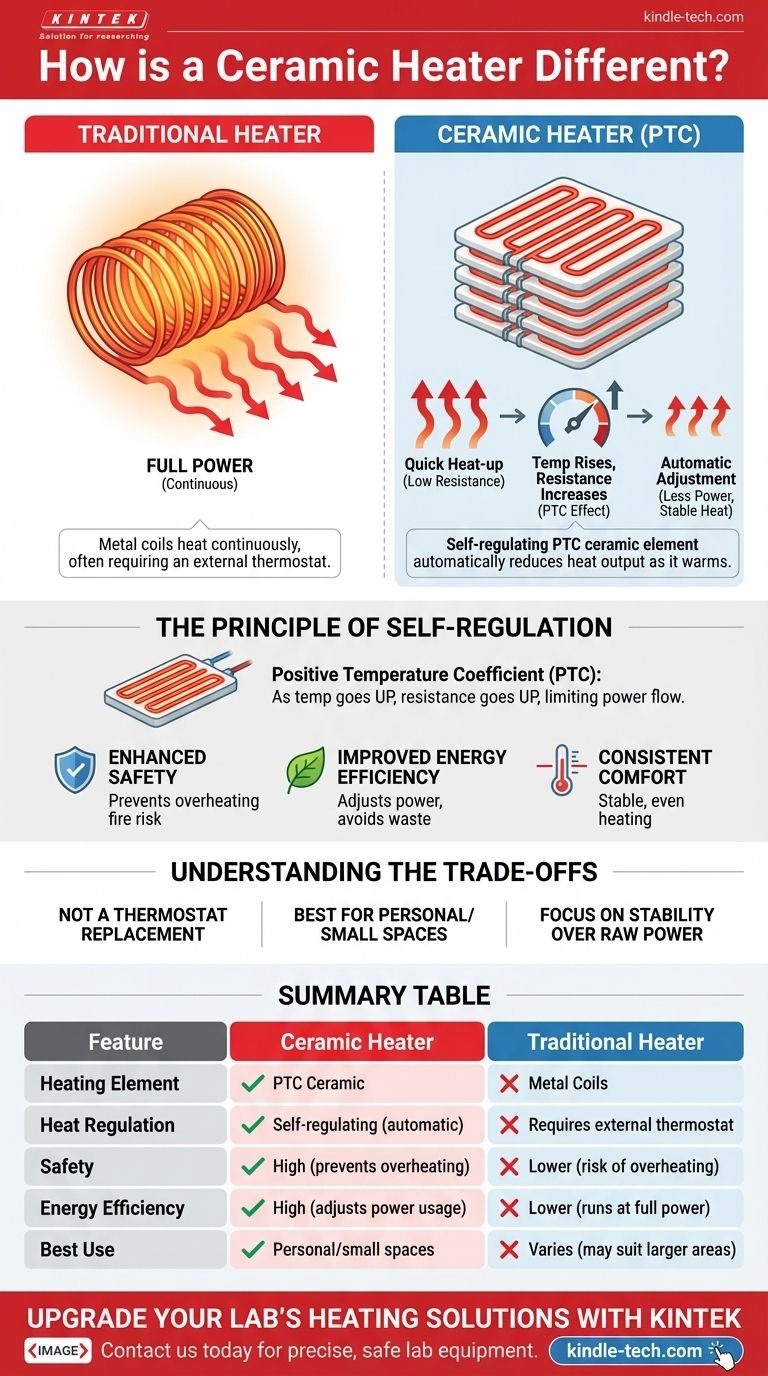

The primary difference in a ceramic heater lies in its unique self-regulating heating element. Unlike traditional heaters that use metal coils which heat continuously at full power, ceramic heaters use a special material that automatically reduces its heat output as it warms up. This intrinsic property makes them fundamentally different in how they manage heat and power.

The defining characteristic of a ceramic heater is its use of a PTC (Positive Temperature Coefficient) ceramic element. This material's electrical resistance naturally increases as its temperature rises, causing it to automatically limit its own heat generation and prevent overheating.

The Principle of Self-Regulation

At the heart of a ceramic heater is a remarkable piece of material science. This technology is not based on complex electronics but on the fundamental physical properties of the ceramic itself.

Understanding PTC Ceramic

The heating elements are made from a specialized ceramic material with a Positive Temperature Coefficient (PTC). This is the key to its unique behavior.

In simple terms, PTC means that as the material's temperature goes up, so does its resistance to the flow of electricity.

How It Works

When you turn the heater on, electricity flows easily through the cool ceramic element, causing it to heat up rapidly.

As the ceramic reaches its designed operating temperature, its internal resistance dramatically increases.

The Automatic Adjustment

This increased resistance naturally throttles the flow of electricity through the element. Less electricity means less heat is generated.

The heater automatically settles into a stable state, producing just enough heat to maintain its temperature. This self-regulation is an inherent characteristic, not something that requires a separate sensor or switch.

The Practical Benefits of This Design

This single characteristic of self-regulation translates into significant real-world advantages, primarily centered around safety and efficiency.

Enhanced Safety

The most critical benefit is enhanced safety. Because the heating element physically cannot overheat beyond a certain point, the risk of fire is significantly reduced compared to a metal element that can continue to get red-hot.

Improved Energy Efficiency

By automatically reducing their power consumption as the ambient temperature rises, ceramic heaters avoid wasting energy. They only draw the necessary power to maintain warmth, unlike basic heaters that run at full capacity until turned off by a thermostat.

Consistent Comfort

This self-adjustment leads to more stable and even heating. It helps avoid the common cycle of a room becoming too hot, the heater shutting off, and then the room becoming too cold before it turns back on.

Understanding the Trade-offs

While highly effective, it's important to understand the context in which ceramic heaters perform best. They are not a universal solution for all heating needs.

Not a Replacement for a Thermostat

Self-regulation applies to the heating element itself, preventing it from overheating. To control the actual temperature of the room, you still need a model with an integrated thermostat that cycles the unit on and off.

Best for Personal and Small Spaces

Ceramic heaters, especially those with fans, are exceptionally good at providing direct, targeted heat or warming a small, enclosed room quickly. They are generally less effective for heating very large or poorly insulated spaces.

Focus on Stability Over Raw Power

The design of a ceramic heater prioritizes safety and stable output. Consequently, its maximum continuous heat output might be less intense than some high-wattage, non-regulating heaters designed for raw power in workshop environments.

Making the Right Choice for Your Goal

Selecting the right heater depends entirely on your specific requirements.

- If your primary focus is safety, especially in an office or bedroom: A ceramic heater is an excellent choice due to its inherent self-regulating properties that prevent the element from reaching dangerous temperatures.

- If your primary focus is energy-efficient supplemental heat: The automatic power reduction of a ceramic element makes it a smart choice for maintaining a comfortable temperature in a single room without wasting electricity.

- If your primary focus is heating a large, open-plan living area or garage: You may want to consider other technologies like an infrared or oil-filled radiator, as a ceramic heater's strength is in more concentrated spaces.

Understanding this core difference empowers you to choose a heater based on its fundamental design, ensuring it aligns perfectly with your needs for safety and efficiency.

Summary Table:

| Feature | Ceramic Heater | Traditional Heater |

|---|---|---|

| Heating Element | PTC Ceramic | Metal Coils |

| Heat Regulation | Self-regulating (automatic) | Requires external thermostat |

| Safety | High (prevents overheating) | Lower (risk of overheating) |

| Energy Efficiency | High (adjusts power usage) | Lower (runs at full power) |

| Best Use | Personal/small spaces | Varies (may suit larger areas with other types) |

Upgrade Your Lab's Heating Solutions with KINTEK

Choosing the right heating equipment is critical for safety and efficiency in your laboratory. Just as a ceramic heater's self-regulating design provides precise, safe warmth, KINTEK's advanced lab equipment ensures reliable and controlled thermal processing for your experiments.

We specialize in supplying high-performance lab furnaces, ovens, and heating elements that offer the same level of precision and safety—tailored to meet the rigorous demands of laboratory environments. Whether you need consistent heating for materials testing or energy-efficient solutions for your lab, KINTEK has the expertise and products to support your work.

Contact us today to find the perfect heating solution for your lab needs. Let’s discuss how our equipment can enhance your research efficiency and safety.

Get in touch with our experts now

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Hexagonal Boron Nitride HBN Ceramic Ring

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

People Also Ask

- What are the high resistance heating elements? Choose the Right Element for Your Temperature & Atmosphere

- How does a heating element heat up? The Science of Joule Heating Explained

- How often do heating elements need to be replaced? Maximize Lifespan by Understanding Failure Causes

- Why are separate thermocouples required for magnesium vacuum sublimation? Ensure Precision & Protect Your Equipment

- Which high temperature furnace elements to be used in oxidizing atmosphere? MoSi2 or SiC for Superior Performance

- What is the design and application of PTC surface heaters? Optimize Direct Contact Heating for Laboratory Precision

- What is the advantage of a quartz heater? Get Instant, Targeted Warmth for Maximum Efficiency

- How does resistance create heat? Unlock the Science of Efficient Energy Conversion