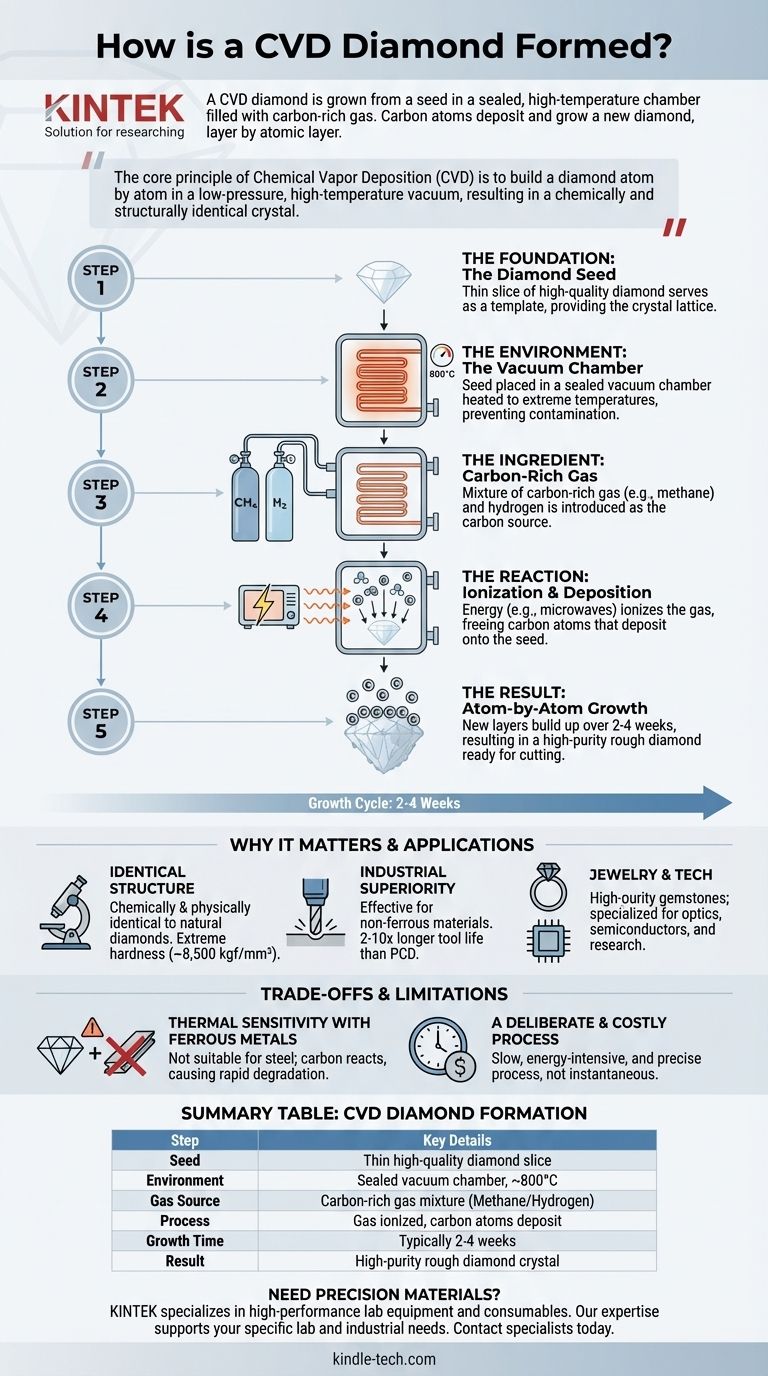

In short, a CVD diamond is grown from a seed. A thin slice of a diamond is placed in a sealed, high-temperature chamber which is then filled with a carbon-rich gas. This gas is broken down, allowing pure carbon atoms to rain down and attach themselves to the seed, growing a new, larger diamond, layer by atomic layer.

The core principle of Chemical Vapor Deposition (CVD) is not to mimic the high-pressure conditions of the deep earth, but to build a diamond atom by atom in a low-pressure, high-temperature vacuum, resulting in a chemically and structurally identical crystal.

The Anatomy of the CVD Process

Understanding the CVD method is about understanding a precisely controlled, additive manufacturing process that happens on an atomic scale. Each step is engineered to ensure the final product has the desired purity and structure.

The Foundation: The Diamond Seed

The process begins with a carefully selected substrate, known as a diamond seed. This is typically a very thin, high-quality slice of a pre-existing diamond, either mined or lab-grown.

This seed acts as the template, providing the foundational crystal lattice upon which the new diamond will grow. It must be thoroughly cleaned to remove any contaminants.

The Environment: The Vacuum Chamber

The diamond seed is placed inside a sealed vacuum chamber. The chamber is heated to an extremely high temperature, typically around 800°C.

This controlled environment is critical for managing the reaction and preventing impurities from contaminating the growing diamond.

The Ingredient: Carbon-Rich Gas

Once the chamber reaches the target temperature, a specific mixture of gases is introduced. This is primarily a carbon-rich gas, such as methane (CH₄), mixed with hydrogen.

These gases serve as the source material, providing the carbon atoms needed to build the diamond.

The Reaction: Ionization and Deposition

Energy, often in the form of microwaves, is introduced into the chamber. This energy ionizes the gas, breaking the molecules apart and freeing the pure carbon atoms.

These carbon atoms then precipitate, or "rain down," onto the cooler diamond seed below. They bond directly to the seed's crystal structure, extending the lattice.

The Result: Atom-by-Atom Growth

This deposition process continues slowly and methodically, building new layers of diamond crystal on top of the seed.

The entire growth cycle typically takes between two and four weeks, resulting in a high-purity, fully formed rough diamond that is then ready to be cut and polished.

Why This Process Matters: Properties and Applications

The CVD method isn't just a novelty; it produces a material with distinct advantages, making it superior for certain demanding applications.

Identical Structure and Hardness

Because a CVD diamond grows from a real diamond seed and is made of the same carbon atoms bonded in the same way, it is chemically and physically identical to a natural diamond.

It possesses extreme hardness, measured at around 8,500 kgf/mm2, making it one of the hardest materials known.

Industrial Superiority

In industrial settings, CVD diamond tools demonstrate remarkable performance. They are exceptionally effective for cutting non-ferrous materials.

Compared to Polycrystalline Diamond (PCD) tools, CVD tools have a tool life that is 2 to 10 times longer and exhibit approximately 35% better performance.

Understanding the Trade-offs and Limitations

No technology is without its specific constraints. The properties that make CVD diamonds exceptional in some areas create limitations in others.

Thermal Sensitivity with Ferrous Metals

The primary limitation of CVD diamond is in machining steel and other ferrous materials.

At the high temperatures generated during cutting, the carbon in the diamond can react chemically with the iron in the steel. This interaction causes the diamond tool to degrade and wear out rapidly, making it an unsuitable choice for this application.

A Deliberate and Costly Process

The slow, weeks-long growth cycle in a highly controlled, energy-intensive environment means that producing CVD diamonds is a significant undertaking. While the method is excellent for growing large, high-quality stones, it is not an instantaneous process.

Making the Right Choice for Your Goal

Understanding the CVD process allows you to select the right material based on your specific needs, whether for industrial tooling or fine jewelry.

- If your primary focus is industrial cutting: CVD diamond is the superior choice for machining non-ferrous materials like aluminum or composites, offering significantly longer tool life.

- If your primary focus is high-quality jewelry: CVD produces diamonds that are optically and chemically indistinguishable from mined diamonds, providing a modern source for high-purity gemstones.

- If your primary focus is advanced technology: The control offered by the CVD process allows for the creation of specialized diamonds for use in optics, semiconductors, and scientific research.

Ultimately, the CVD process represents a shift from geological chance to deliberate engineering, producing a material that is diamond in every essential way.

Summary Table:

| CVD Diamond Formation Step | Key Details |

|---|---|

| Seed | Thin slice of a high-quality diamond |

| Environment | Sealed vacuum chamber heated to ~800°C |

| Gas Source | Carbon-rich gas mixture (e.g., methane & hydrogen) |

| Process | Gas ionized; carbon atoms deposit on seed |

| Growth Time | Typically 2 to 4 weeks |

| Result | High-purity, rough diamond crystal |

Need precision materials for your lab or manufacturing process? KINTEK specializes in high-performance lab equipment and consumables. Whether you're researching advanced materials like CVD diamonds or require reliable tools for your industrial applications, our expertise can help you achieve superior results. Contact our specialists today to discuss how we can support your specific laboratory needs.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- Which is better lab grown or natural diamond? A Clear Guide to Choosing Your Perfect Stone

- Does the chemical vapor deposition be used for diamonds? Yes, for Growing High-Purity Lab Diamonds

- Do lab-grown diamonds last as long? Yes, They Offer the Same Unmatched Durability

- What is chemical vapor deposition of diamond? Grow High-Purity Diamonds Atom-by-Atom

- Are artificial diamonds as strong as natural diamonds? Discover the Truth About Lab-Grown Diamond Durability

- Are CVD diamonds synthetic? Discover the Truth About Lab-Grown Diamonds

- What are the advantages of lab-grown diamonds? Identical Quality, Ethical & Cost Benefits

- How plasma is used in diamond coating films? Unlock the Power of MPCVD for Superior Coatings