In ultra-low temperature (ULT) freezers, temperature tracking is managed through two primary methods: traditional charted weekly recorders or more modern digital monitoring systems. These tools are not merely accessories; they are the core components that provide a continuous, verifiable record of the internal environment, ensuring both sample integrity and regulatory compliance.

The method of temperature tracking in an ultra freezer is less about the feature itself and more about the philosophy of risk management. While traditional chart recorders offer a physical audit trail, modern digital systems provide the real-time data, proactive alerts, and integration necessary to truly safeguard critical assets.

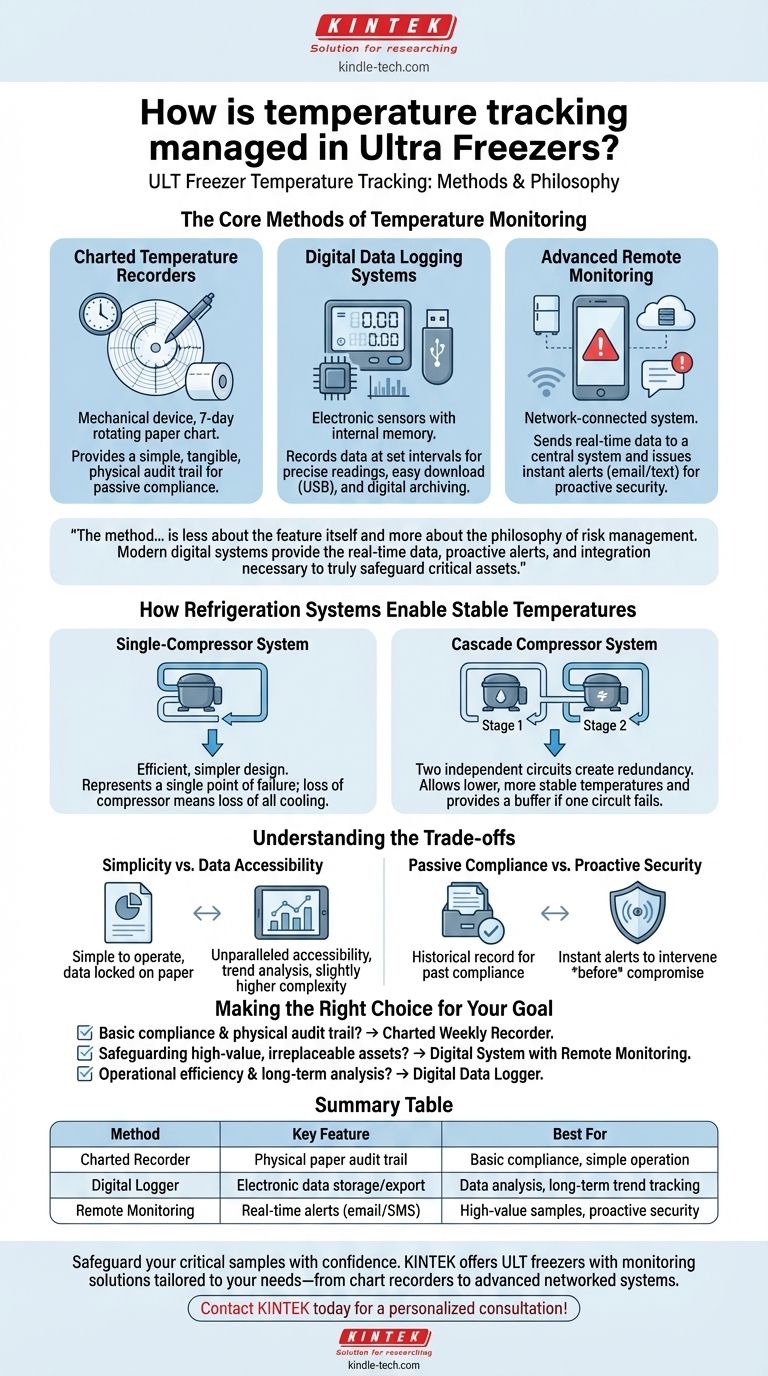

The Core Methods of Temperature Monitoring

Understanding how a freezer's temperature is tracked requires looking at the two main technologies employed. Each serves the same fundamental purpose but offers vastly different levels of accessibility and proactive control.

Charted Temperature Recorders

A charted recorder is a mechanical device, often featuring a circular paper chart that rotates over a seven-day period.

An ink-tipped stylus is connected to a temperature probe, physically drawing a continuous line on the chart as it turns. This provides a simple, tangible, and easy-to-read history of temperature performance for a given week.

Digital Data Logging Systems

Digital systems replace the paper chart with electronic sensors and a digital display. They offer a much higher degree of precision in their readings.

These units record temperature data at set intervals to internal memory. This data can then be downloaded, typically via a USB drive, for analysis, archiving, and reporting.

Advanced Remote Monitoring

This is the modern evolution of the digital system. In addition to onboard data logging, these freezers connect to a network.

They can send real-time data to a central monitoring system and, most critically, issue instant alerts via email or text message if the temperature deviates from the set range. This transforms monitoring from a passive record to an active security system.

How Refrigeration Systems Enable Stable Temperatures

The monitoring system is only as good as the refrigeration system it oversees. The stability of the temperature being recorded is determined by the freezer's mechanical core.

The Role of the Compressor

The compressor is the heart of the refrigeration system, responsible for circulating refrigerant to remove heat from the freezer's interior. The design of this system directly impacts the unit's reliability and performance.

Single-Compressor Systems

Some freezers use a single, high-power, hermetically sealed compressor. This design is efficient and mechanically simpler.

However, it also represents a single point of failure. If this one compressor fails, the entire cooling capacity of the freezer is lost.

Cascade Compressor Systems

A cascade system uses two independent refrigeration circuits. These circuits are connected in a way that the first stage cools the second stage.

This two-part system creates redundancy and allows for lower, more stable temperatures to be achieved and maintained. If one circuit experiences an issue, the other may provide a buffer, slowing the rate of temperature change and allowing more time for intervention.

Understanding the Trade-offs

Choosing between monitoring systems involves clear trade-offs in cost, compliance, and proactive protection.

Simplicity vs. Data Accessibility

Chart recorders are exceptionally simple to operate and interpret. However, the data is locked onto a physical piece of paper, making analysis or sharing difficult.

Digital systems offer unparalleled data accessibility. Records can be easily stored, shared, and analyzed to spot trends, but this comes with a slightly higher degree of technical complexity.

Passive Compliance vs. Proactive Security

A chart recorder is excellent for passive compliance. It creates a historical record that proves the freezer was operating correctly in the past.

A networked digital system provides proactive security. An instant alert about a temperature deviation allows you to intervene and save valuable samples before they are compromised.

Making the Right Choice for Your Goal

Your choice of temperature management depends entirely on the value of your stored materials and your operational requirements.

- If your primary focus is basic compliance and a physical audit trail: A charted weekly temperature recorder provides a simple, reliable, and tangible record.

- If your primary focus is safeguarding high-value, irreplaceable assets: A digital system with remote monitoring and alerts is the essential choice to protect your materials proactively.

- If your primary focus is operational efficiency and long-term performance analysis: A digital data logger offers easily exportable data to track trends and ensure freezer health over time.

Ultimately, the right monitoring system provides verifiable proof that your freezer's critical environment is stable and secure.

Summary Table:

| Method | Key Feature | Best For |

|---|---|---|

| Charted Recorder | Physical paper audit trail | Basic compliance, simple operation |

| Digital Logger | Electronic data storage/export | Data analysis, long-term trend tracking |

| Remote Monitoring | Real-time alerts (email/SMS) | High-value samples, proactive security |

Safeguard your critical samples with confidence. The right temperature tracking system is vital for protecting your research and ensuring compliance. KINTEK specializes in lab equipment and consumables, offering a range of ULT freezers with monitoring solutions tailored to your laboratory's specific needs—from reliable chart recorders to advanced networked systems with instant alerts. Let our experts help you choose the perfect solution to protect your assets. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

People Also Ask

- How does a high-precision MFC regulate argon flow for alpha-Al2O3 coating? Optimize Your Deposition Process Quality

- What are the different types of heat treatment process? A Guide to Hardening, Softening & Brazing

- What is the process of thin film coating? A Guide to Precision Layer Deposition

- What are the advantages of microwave heating for HEA catalysts? Unlock Superior OER Efficiency with Rapid Sintering

- What is the definition of deposition in chemistry? Understand the Two Key Meanings

- How does biomass compare to fossil fuels? A Clear Breakdown of Carbon Impact & Energy Use

- What are the advantages of powder metallurgy process? Achieve Cost-Effective, High-Precision Manufacturing

- How hot can metal get? From Melting Points to Plasma Temperatures