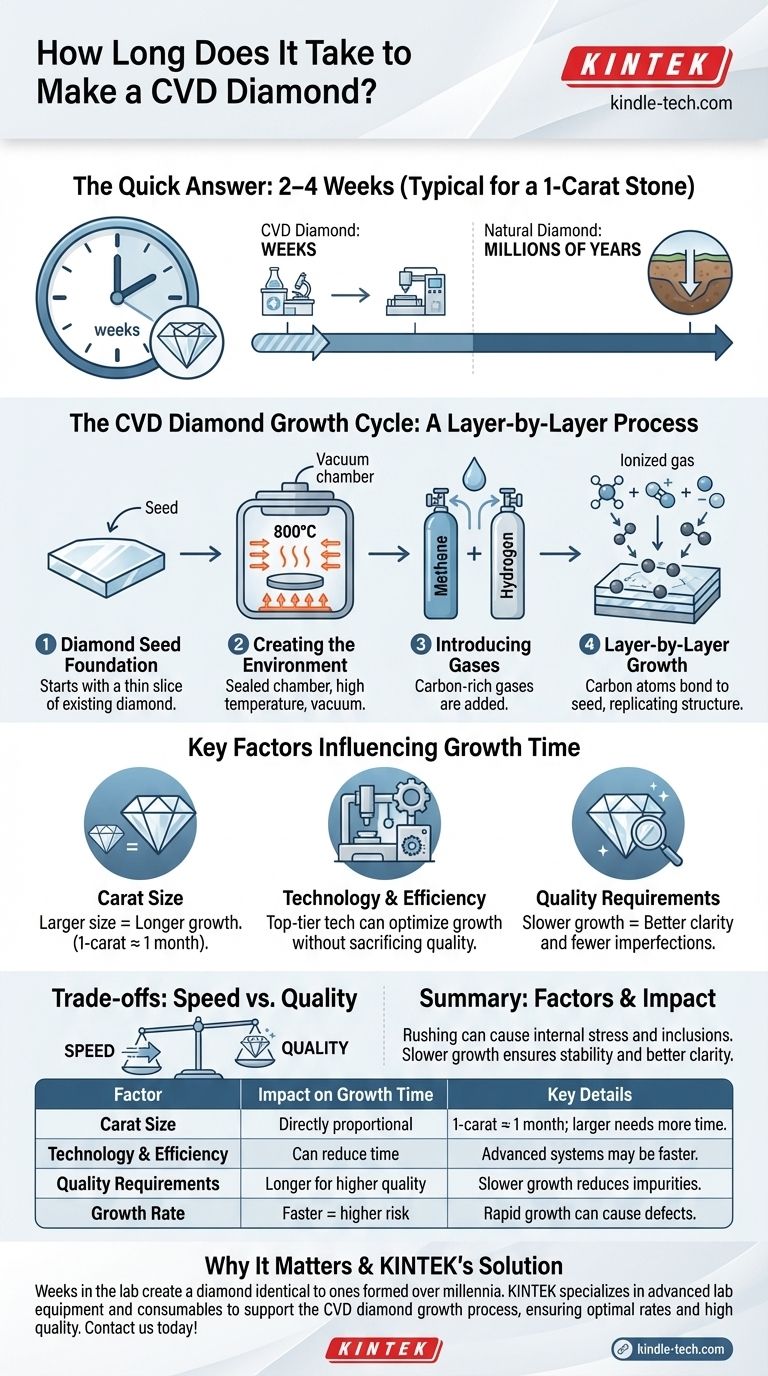

In short, a CVD diamond typically takes two to four weeks to create. For a standard 1-carat stone, the process generally requires about a month, though the exact duration can vary from a few days to several weeks depending on the desired size and the specific technology being used.

Unlike the millions of years required for natural diamond formation, the CVD process is a highly controlled manufacturing cycle measured in weeks. The central insight is that growth time is a direct trade-off against the diamond's size and final quality.

The CVD Diamond Growth Cycle Explained

The creation time for a Chemical Vapor Deposition (CVD) diamond is dictated by its meticulous, layer-by-layer formation process. Understanding these steps clarifies why it is a matter of weeks, not hours or days.

The Diamond Seed Foundation

The process begins with a "seed," which is a very thin, high-quality slice of an existing diamond. This seed acts as the foundational template upon which the new diamond will grow.

Creating the Perfect Environment

This seed is placed inside a sealed, high-temperature vacuum chamber. The vacuum is critical to remove any contaminants that could interfere with the growth, and the chamber is heated to around 800°C.

Introducing Carbon-Rich Gases

The chamber is then filled with a mixture of carbon-rich gases, most commonly methane, along with other gases like hydrogen. These gases are the source material for the new diamond.

The Layer-by-Layer Growth

At high temperatures, the gases are ionized, which breaks the molecules apart. This process releases pure carbon atoms, which then rain down and bond to the diamond seed, replicating its crystal structure one atomic layer at a time.

Key Factors That Determine Growth Time

While the fundamental process is consistent, several variables can significantly alter the total time required to grow a finished diamond.

The Impact of Carat Size

This is the most significant factor. A larger diamond requires more layers of carbon to be deposited, which directly translates to a longer growth period. A 1-carat diamond takes roughly a month, while larger stones will require more time in the chamber.

The Role of Technology and Efficiency

Different producers use proprietary variations of the CVD process. Top-tier labs have refined their technology to optimize growth rates without compromising the quality of the stone, sometimes producing 1-carat diamonds in less than a month.

The Pursuit of Higher Quality

Growing a diamond too quickly can introduce internal stress or trap impurities within the crystal lattice. A slower, more stable growth rate often results in a diamond with better clarity and fewer imperfections.

Understanding the Trade-offs: Speed vs. Quality

The duration of the CVD process is not just a technical limitation; it is a deliberate choice that balances production efficiency with the quality of the final gemstone.

The Risk of Rushing the Process

Accelerating the deposit of carbon atoms can disrupt the perfect crystal structure. This can lead to internal graining or inclusions that lower the diamond's clarity grade and overall value.

Why Slower is Often Better

Many producers opt for a more measured growth period to ensure maximum stability. This careful cultivation results in a more flawless and structurally sound diamond, demonstrating that the time invested is a crucial element of the quality control process.

What This Means for Your Choice

Understanding the growth timeline provides a deeper appreciation for the technology behind lab-grown diamonds and how it impacts the final product.

- If your primary focus is understanding the technology: Recognize that CVD is a precise manufacturing process where time is a controlled variable, unlike the geologic chance of natural diamond formation.

- If your primary focus is assessing value: The production time of several weeks explains the efficiency and scalability of lab-grown diamonds, which is a major factor in their price point compared to mined equivalents.

- If your primary focus is quality: View the growth period not as a delay, but as a necessary phase of cultivation required to produce a high-quality gemstone.

Ultimately, the weeks spent in a laboratory allow for the creation of a diamond that is physically, chemically, and optically identical to one that took millennia to form deep within the Earth.

Summary Table:

| Factor | Impact on Growth Time | Key Details |

|---|---|---|

| Carat Size | Directly proportional | A 1-carat diamond takes ~1 month; larger stones require more time |

| Technology & Efficiency | Can reduce time | Advanced systems may produce 1-carat diamonds in under a month |

| Quality Requirements | Longer for higher quality | Slower growth reduces impurities and improves clarity |

| Growth Rate | Faster = higher risk | Rapid growth can cause internal stress and inclusions |

Need precise, high-quality lab-grown diamonds for your research or commercial applications? At KINTEK, we specialize in advanced lab equipment and consumables that support the entire CVD diamond growth process. Our expertise ensures you achieve optimal growth rates without compromising on diamond quality. Contact us today to discuss how our solutions can enhance your laboratory's efficiency and output.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the chemical process used to make synthetic diamonds? Discover HPHT vs. CVD Methods

- How does the general process of Chemical Vapor Deposition (CVD) work? Mastering Thin-Film Uniformity

- What is sputter damage? A Guide to Protecting Sensitive Materials During Thin-Film Deposition

- What is the function of a reaction vessel with controlled humidity in CVD? Master Silicone Nanofilament Growth

- What is plasma in RF sputtering? The Engine of Thin-Film Deposition

- What is difference between RF and DC sputtering? Choose the Right Method for Your Material

- What methods are used to deposit thin films? A Guide to PVD, CVD, and ALD Techniques

- What are the different types of chemical deposition? A Guide to Thin-Film Coating Methods