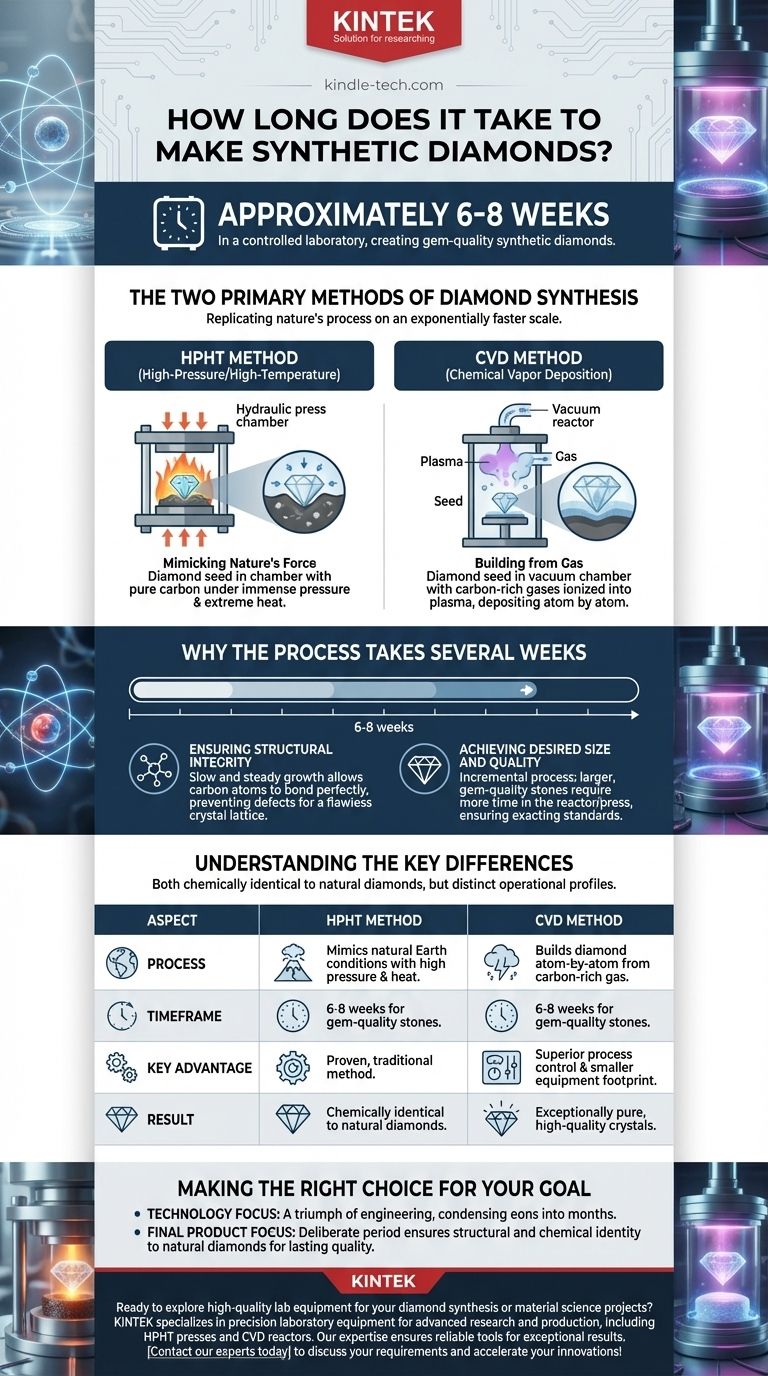

In a controlled laboratory, creating a gem-quality synthetic diamond takes approximately six to eight weeks. This timeframe is the result of highly sophisticated technological processes that replicate the conditions under which diamonds form naturally, but on an exponentially faster scale.

The core takeaway is that the several-week creation period for a synthetic diamond is not a limitation, but a necessary duration for two primary methods—HPHT and CVD—to carefully construct a stone with the same physical and chemical properties as a natural diamond.

The Two Primary Methods of Diamond Synthesis

While several techniques exist, the vast majority of lab-grown diamonds are created using one of two well-established methods. Each process is a marvel of material science, designed to manipulate carbon atoms under extreme conditions.

The HPHT Method: Mimicking Nature's Force

High-Pressure/High-Temperature (HPHT) is the more traditional method of diamond synthesis. It directly mimics the natural formation process that occurs deep within the Earth's mantle.

In this technique, a small diamond seed is placed in a chamber with a source of pure carbon. The chamber is then subjected to immense pressure and extreme heat, causing the carbon to melt and crystallize around the seed, forming a larger diamond.

The CVD Method: Building from Gas

Chemical Vapor Deposition (CVD) is a more modern approach that builds a diamond atom by atom. The process begins with a diamond seed placed inside a vacuum chamber.

The chamber is then filled with carbon-rich gases, such as methane and hydrogen. These gases are ionized into a plasma, which causes the carbon atoms to break away and deposit onto the diamond seed, gradually growing a larger, high-quality diamond layer by layer.

Why the Process Takes Several Weeks

While a dramatic acceleration compared to the millions of years required for natural formation, the 6-8 week timeline is a deliberate and crucial aspect of creating a high-quality gem.

Ensuring Structural Integrity

The growth of a diamond crystal must be slow and steady. Rushing the process, whether by altering temperatures in HPHT or gas flow in CVD, can introduce structural defects and inclusions.

The multi-week duration allows the carbon atoms to bond perfectly into the rigid, flawless crystal lattice that gives a diamond its renowned hardness and brilliance.

Achieving Desired Size and Quality

The final size of the diamond is directly related to how long it is allowed to grow. The process is incremental, and creating larger, gem-quality stones simply requires more time in the reactor or press.

This controlled environment, a key advantage of the CVD method in particular, ensures the final product meets exacting quality standards.

Understanding the Key Differences

Both HPHT and CVD produce diamonds that are chemically identical to their natural counterparts, but the methods themselves have distinct operational profiles.

Process Control

The CVD method is generally regarded as offering superior process control. Because it builds the diamond layer by layer from a gas, technicians can fine-tune the environment to produce exceptionally pure crystals.

Equipment and Scale

The HPHT method often requires very large, heavy machinery to generate the incredible pressures needed for crystallization. In contrast, CVD reactors typically have a smaller equipment footprint, offering more flexibility in a laboratory setting.

Making the Right Choice for Your Goal

Understanding the creation timeline provides context for the value and nature of lab-grown diamonds.

- If your primary focus is on the technology: Recognize that the six-to-eight-week timeframe is a triumph of engineering, condensing a geological process that takes eons into a matter of months.

- If your primary focus is on the final product: Know that this deliberate manufacturing period ensures the synthetic diamond you receive is structurally and chemically identical to a natural one, built for lasting quality.

Ultimately, modern science has mastered the ability to replicate one of nature's most extreme and lengthy creation processes with remarkable precision and speed.

Summary Table:

| Aspect | HPHT Method | CVD Method |

|---|---|---|

| Process | Mimics natural Earth conditions with high pressure & heat | Builds diamond atom-by-atom from carbon-rich gas |

| Timeframe | 6-8 weeks for gem-quality stones | 6-8 weeks for gem-quality stones |

| Key Advantage | Proven, traditional method | Superior process control & smaller equipment footprint |

| Result | Chemically identical to natural diamonds | Exceptionally pure, high-quality crystals |

Ready to explore high-quality lab equipment for your diamond synthesis or material science projects? At KINTEK, we specialize in providing precision laboratory equipment and consumables tailored to advanced research and production needs. Whether you're working with HPHT presses, CVD reactors, or other sophisticated processes, our expertise ensures you have the reliable tools to achieve exceptional results. Contact our experts today to discuss how we can support your laboratory's specific requirements and help you accelerate your innovations!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit