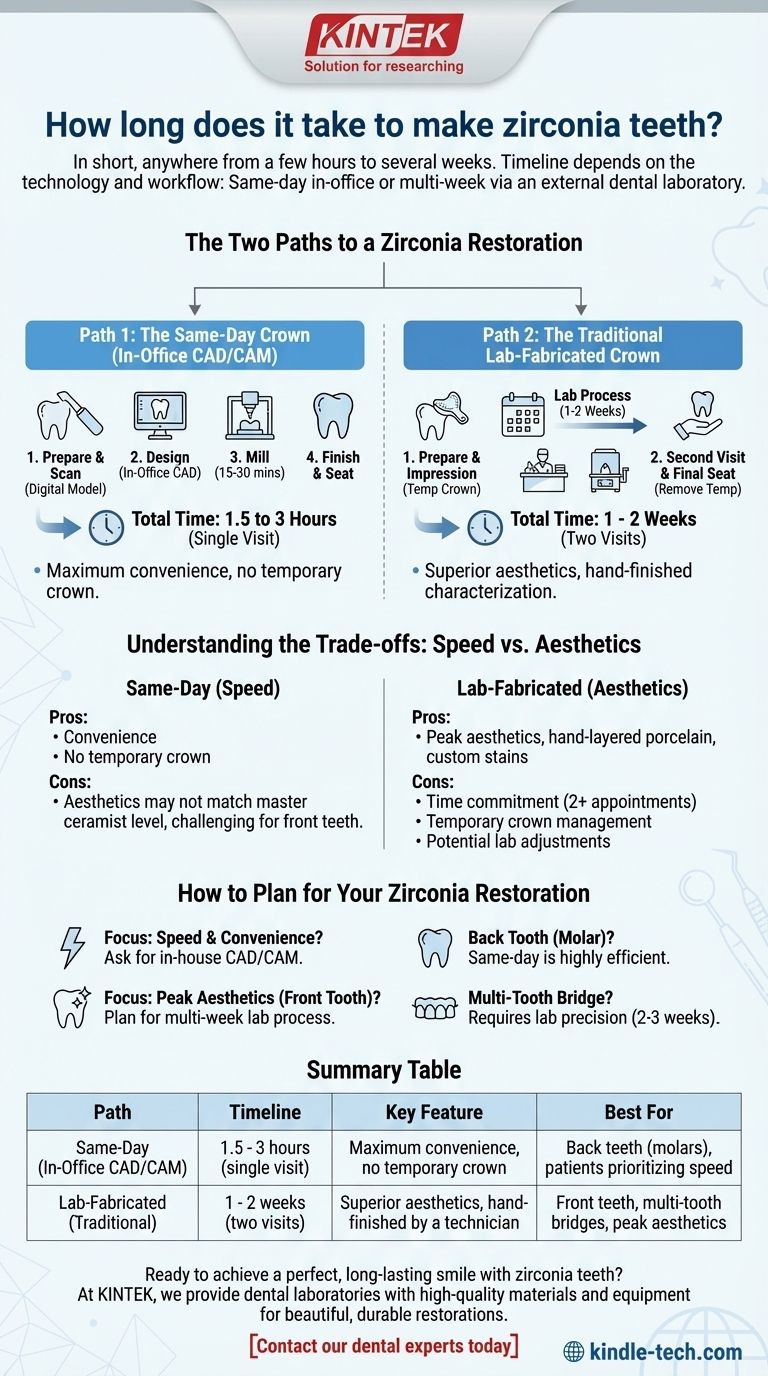

In short, creating a zirconia tooth can take anywhere from a few hours to several weeks. The exact timeline is not determined by the material itself, but by the technology and workflow your dentist uses—either fabricating it in-office for a same-day result or sending it to an external dental laboratory, which is a multi-week process.

The single greatest factor dictating the timeline for a zirconia restoration is whether your dentist has in-house CAD/CAM milling technology. This determines if you can complete the procedure in one visit or if it will require two appointments spread 1-2 weeks apart.

The Two Paths to a Zirconia Restoration

The process for getting a zirconia crown, bridge, or veneer follows one of two distinct timelines. The path you take depends entirely on your dentist's equipment and approach.

Path 1: The Same-Day Crown (In-Office CAD/CAM)

Some dental offices have invested in Chairside CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) systems, with CEREC being the most well-known brand.

This technology condenses the entire process into a single appointment.

First, your dentist prepares the tooth and uses a digital scanner to create a 3D model of your mouth. This model is then used to design the restoration on a computer right in the treatment room.

Once the design is finalized, it's sent to an in-office milling machine. This machine carves your new tooth from a solid block of zirconia in about 15-30 minutes. Your dentist will then perform final finishing, staining, and glazing before permanently cementing it in place.

The entire appointment for a single same-day zirconia crown typically takes 1.5 to 3 hours. The main advantage is avoiding a temporary crown and a second visit.

Path 2: The Traditional Lab-Fabricated Crown

The more traditional and still very common method involves an external dental laboratory. This process requires at least two separate appointments.

During the first visit, your dentist prepares the tooth and takes an impression. This can be a physical putty impression or a digital scan. You will be fitted with a temporary crown to protect the tooth while the permanent one is being made.

The impression and specifications are then sent to a dental lab. Over the next 1 to 2 weeks, a specialized lab technician designs and fabricates your zirconia restoration. This extended time allows for more detailed, hand-finished color and characterization.

During the second visit, the temporary crown is removed, and the final zirconia crown is tried in. After confirming a perfect fit and appearance, your dentist permanently cements it into place.

Understanding the Trade-offs: Speed vs. Aesthetics

Choosing between a same-day or lab-fabricated crown involves a key trade-off between convenience and the potential for fine-tuned aesthetics.

The Case for Same-Day Crowns

The primary benefit is convenience. Completing the entire procedure in one visit saves you time and means you never have to wear a temporary restoration, which can sometimes be uncomfortable or fall off.

The main limitation is that the aesthetics, while often excellent, may not reach the same level of artistry as a crown hand-finished by a master ceramist in a lab. The color and translucency are good, but creating a perfect match for a highly visible front tooth can be more challenging with this method.

The Case for Lab-Fabricated Crowns

The key advantage is peak aesthetics. A skilled dental technician can layer porcelain, apply custom stains, and precisely mimic the appearance of your natural teeth. This is why lab-fabricated crowns are often considered the gold standard for front teeth.

The obvious downside is the time commitment. The process requires a minimum of two appointments spaced weeks apart and the need to manage a temporary crown in the interim. There is also a small risk of the crown needing to be sent back to the lab for adjustments, further extending the timeline.

How to Plan for Your Zirconia Restoration

Your conversation with your dentist should focus on your priorities and the specific tooth being restored.

- If your primary focus is speed and convenience: Ask your dentist directly if they offer same-day zirconia crowns using in-house CAD/CAM technology.

- If your primary focus is the highest possible aesthetic outcome for a front tooth: A traditional, lab-fabricated crown is often the superior choice, so you should plan for a multi-week process.

- If you are restoring a back tooth (molar): A same-day zirconia crown is an excellent and highly efficient option, as the functional strength of zirconia is paramount.

- If you need a multi-tooth bridge: This almost always requires the precision and expertise of an external dental lab, so expect a 2-to-3-week timeline.

Understanding these timelines and trade-offs will empower you to have a productive discussion with your dentist and set clear expectations for your treatment.

Summary Table:

| Path | Timeline | Key Feature | Best For |

|---|---|---|---|

| Same-Day (In-Office CAD/CAM) | 1.5 - 3 hours (single visit) | Maximum convenience, no temporary crown | Back teeth (molars), patients prioritizing speed |

| Lab-Fabricated (Traditional) | 1 - 2 weeks (two visits) | Superior aesthetics, hand-finished by a technician | Front teeth, multi-tooth bridges, peak aesthetics |

Ready to achieve a perfect, long-lasting smile with zirconia teeth?

At KINTEK, we provide dental laboratories with the high-quality materials and equipment needed to create beautiful, durable zirconia restorations. Whether your practice uses the traditional lab-fabricated method or an in-office CAD/CAM system, our products support exceptional results.

Let us help you deliver the best to your patients. Contact our dental experts today to discuss how KINTEK can support your laboratory's needs with reliable consumables and equipment.

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- What is the importance of using PTFE tweezers during the acid cleaning of gold and titanium reaction cell parts?

- What physical changes occur to ceramic materials like zirconia during sintering? Maximize Density and Strength

- How much heat can a ceramic crucible take? Find the Right Crucible for Your High-Temp Process

- Selecting Alumina or Zirconia Crucibles for LLZTO Synthesis: Key Factors for Pure Solid-State Electrolytes

- What are the applications of zirconia ceramics? Unlock High-Performance Solutions for Extreme Environments