To ensure effective operation, the ideal ball charge for a ball mill should be between 30% and 50% of the total internal volume of the mill cylinder. This range provides the necessary balance between the grinding media and the material being processed, allowing for efficient size reduction through both impact and attrition.

The core principle is balancing impact energy with material interaction. Loading a mill with a 30-50% ball charge maximizes the grinding action by allowing balls to fall with sufficient force without being cushioned by an excessive ball mass or a lack of space.

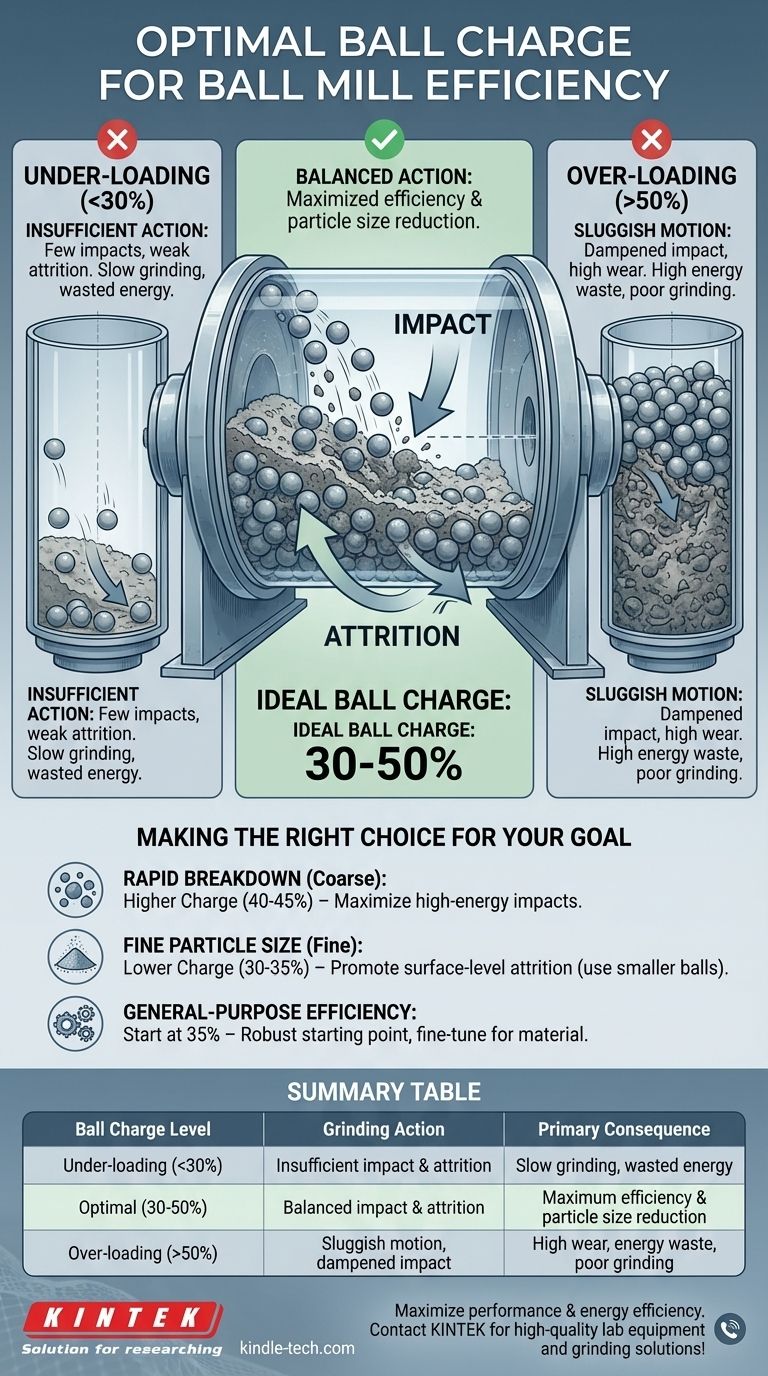

How Ball Charge Dictates Grinding Efficiency

The percentage of the mill filled with grinding media—known as the ball charge—is the single most important operational parameter. It directly controls the mechanism and effectiveness of the size reduction process.

The Dynamics of Ball Motion

Inside a rotating mill, the balls are lifted up the side of the shell and then fall back down onto the material. The nature of this fall is critical. At the correct charge level and speed, the balls cascade and cataract, creating the two primary forces for grinding.

Impact occurs when balls fall from near the top of the shell, striking the material below with significant force. This is essential for breaking down larger particles.

Attrition happens when balls slide and roll against each other and the mill liner, creating a shearing action that grinds finer particles.

Why 30-50% is the Optimal Range

This specific range creates the ideal conditions for both impact and attrition. It ensures there is enough open space for the balls to achieve a proper trajectory and fall with maximum energy.

Simultaneously, it guarantees a sufficient number of balls are present to create the frequent collisions and shearing forces needed for efficient grinding throughout the material bed.

Understanding the Trade-offs of Ball Charge

Deviating from the optimal 30-50% range leads to predictable and significant drops in performance. Understanding these consequences is key to troubleshooting and optimizing your process.

The Problem with Under-loading (<30%)

When the ball charge is too low, the grinding action becomes highly inefficient. There are simply not enough impact and attrition events to process the material effectively.

The few balls present may be cushioned by the material, preventing hard, particle-shattering impacts. This results in extremely slow grinding rates and wasted energy.

The Problem with Over-loading (>50%)

Counterintuitively, adding too many balls severely hinders performance. When the charge exceeds 50%, the void space within the mill disappears.

The balls can no longer achieve a free fall. Instead of a powerful cascade, the mass of balls tends to roll over itself in a sluggish motion, dampening any real impact force. This primarily generates friction and wear on the balls and liner without effective size reduction, wasting significant energy.

Making the Right Choice for Your Goal

Your ideal ball charge depends on your specific material and desired outcome. Use the 30-50% range as your guide and adjust based on your primary objective.

- If your primary focus is rapid breakdown of coarse material: Start with a charge on the higher end of the scale (around 40-45%) to maximize the number of high-energy impacts.

- If your primary focus is achieving a very fine final particle size: Consider a charge on the lower end (around 30-35%) with smaller balls to promote more surface-level attrition over high-impact crushing.

- If your primary focus is general-purpose efficiency: Begin with a 35% charge and evaluate the output. This is a robust starting point that can be fine-tuned for nearly any material.

Optimizing your ball charge is the most direct path to improving your ball mill's performance and energy efficiency.

Summary Table:

| Ball Charge Level | Grinding Action | Primary Consequence |

|---|---|---|

| Under-loading (<30%) | Insufficient impact & attrition | Slow grinding, wasted energy |

| Optimal (30-50%) | Balanced impact & attrition | Maximum efficiency & particle size reduction |

| Over-loading (>50%) | Sluggish motion, dampened impact | High wear, energy waste, poor grinding |

Maximize your ball mill's performance and energy efficiency with the right grinding media. KINTEK specializes in high-quality lab equipment and consumables, including ball mills and grinding balls, to serve your laboratory's precise size reduction needs. Our experts can help you select the optimal ball charge for your specific material and goals. Contact us today to optimize your grinding process!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is the role of a planetary ball mill in preparing Cu-doped TiO2? Optimize Your Solid-State Synthesis

- What balls are used in ball mills? Select the Right Grinding Media for Your Lab

- What is the function of a planetary ball mill in LLZO electrolyte synthesis? Unlock High-Energy Mixing Precision

- How does a dry impact-blending device compare to a planetary ball mill? Optimize Your Solid-State Battery Composites

- What are the advantages of Zirconia (ZrO2) for cellulose reduction? Ensure Peak Purity and High-Energy Milling Efficiency

- Why is ball milling equipment required in Cold Sintering? Master Particle Refinement for Optimal Density

- What is the primary function of a planetary ball mill in LAGP synthesis? Achieve High-Purity Solid-State Electrolytes

- What advantages does a planetary ball mill offer over standard ball milling? Boost YAG Powder Sintering Activity