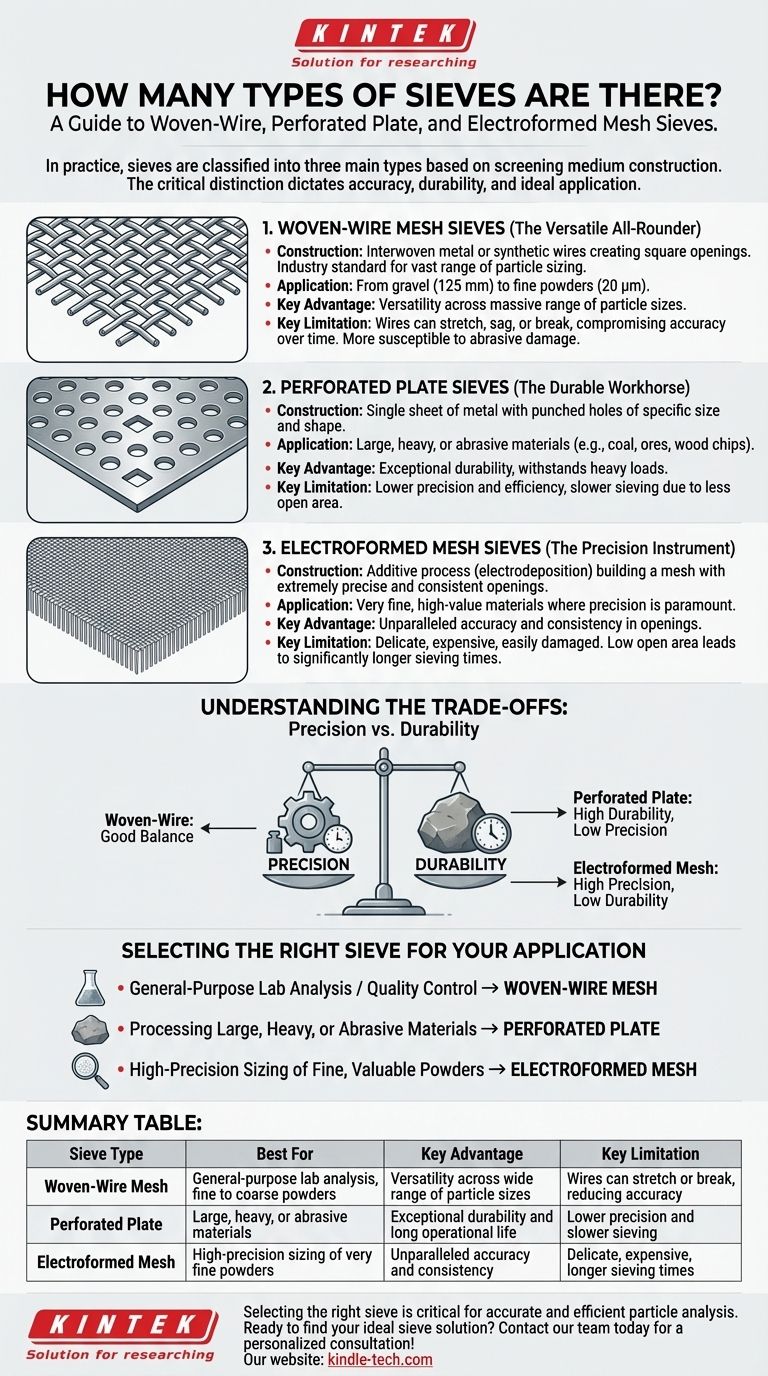

In practice, sieves are classified into three main types based on the construction of their screening medium. These types are woven-wire mesh, perforated metal plates, and electroformed mesh. Each is designed for a distinct purpose, ranging from general-purpose analysis to high-precision particle sizing.

The critical distinction between sieve types is not simply their material, but how the screening medium is constructed. This construction directly dictates the sieve's accuracy, durability, and ideal application, making the choice dependent on the material being tested and the precision required.

The Three Core Sieve Types Explained

Understanding the fundamental design of each sieve type is the key to selecting the right tool. The differences in their screening surfaces—the part that does the actual work of separation—are significant.

Woven-Wire Mesh Sieves

This is the most common and versatile type of sieve. It is constructed from metal or synthetic wires that are interwoven to create square openings.

Woven-wire mesh is considered the industry standard for a vast range of particle sizing applications. Its opening sizes can range from as large as 125 mm down to just 20 micrometers (µm), making it suitable for everything from gravel to fine powders.

Perforated Plate Sieves

Perforated plate sieves are made from a single sheet of metal into which holes of a specific size and shape (typically round or square) have been punched.

These sieves are exceptionally durable and are primarily used for sizing large, heavy, or abrasive materials where the robustness of woven wire might be insufficient. Common applications include the analysis of coal, ores, and wood chips.

Electroformed Mesh Sieves

Electroformed sieves represent the pinnacle of precision. They are not woven or punched but created through an additive process called electrodeposition, building a mesh with extremely precise and consistent openings.

This method allows for exceptionally fine and accurate apertures, making electroformed mesh the ideal choice for sizing very fine, high-value materials where precision is paramount.

Understanding the Trade-offs: Precision vs. Durability

No single sieve type is universally superior; each comes with inherent strengths and weaknesses. The choice almost always involves a trade-off between the precision of the measurement and the durability of the instrument.

Woven-Wire Mesh: The Versatile All-Rounder

The primary advantage of woven wire is its versatility across a massive range of particle sizes. It provides a good balance of open area for efficient sieving and reasonable accuracy.

However, the wires can stretch, sag, or break with use, which can subtly alter the aperture size and compromise measurement accuracy over time. They are also more susceptible to damage from abrasive particles than perforated plates.

Perforated Plate: The Durable Workhorse

The main strength of a perforated plate is its outstanding durability. It can withstand heavy, abrasive loads without damage or loss of accuracy, ensuring a long operational life.

The trade-off is lower precision and efficiency. The manufacturing process limits the minimum hole size, and the plate has less open area than a wire mesh, which can slow down the sieving process.

Electroformed Mesh: The Precision Instrument

Electroformed mesh offers unparalleled accuracy and consistency in its openings, which is essential for scientific research or quality control of fine powders.

This precision comes at a cost. These sieves are very delicate, expensive, and easily damaged by overloading or improper handling. Their very low open area also means sieving times can be significantly longer.

Selecting the Right Sieve for Your Application

Your choice should be guided by the material you are working with and the level of accuracy your results demand.

- If your primary focus is general-purpose lab analysis or quality control: Woven-wire mesh offers the best balance of versatility, efficiency, and accuracy for most standard applications.

- If your primary focus is processing large, heavy, or abrasive materials: Perforated plate sieves provide the necessary durability to ensure reliable, long-term performance.

- If your primary focus is high-precision sizing of fine, valuable powders: Electroformed mesh is the only choice when exact particle dimensions and repeatable accuracy are non-negotiable.

Understanding these fundamental differences empowers you to select a tool perfectly suited to the demands of your material and the goals of your analysis.

Summary Table:

| Sieve Type | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Woven-Wire Mesh | General-purpose lab analysis, fine to coarse powders | Versatility across a wide range of particle sizes | Wires can stretch or break, reducing accuracy over time |

| Perforated Plate | Large, heavy, or abrasive materials (e.g., coal, ores) | Exceptional durability and long operational life | Lower precision and slower sieving due to less open area |

| Electroformed Mesh | High-precision sizing of very fine, valuable powders | Unparalleled accuracy and consistency of openings | Delicate, expensive, and longer sieving times |

Selecting the right sieve is critical for accurate and efficient particle analysis. At KINTEK, we specialize in providing high-quality laboratory equipment, including a full range of sieves tailored to your specific needs—from robust perforated plates for abrasive materials to precision electroformed meshes for fine powders. Our experts can help you choose the perfect tool to ensure reliable results and maximize your lab's productivity.

Ready to find your ideal sieve solution? Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials