The short answer is this: A production-quality injection mold can cost anywhere from $5,000 for a simple design to over $100,000 for a complex, high-volume tool. While this range seems vast, the price is not arbitrary. It is a direct calculation based on the specific design of the part you intend to produce.

The most critical takeaway is that the cost of an injection mold is not a fixed price for a product, but a direct reflection of your part's complexity and your production goals. To control the mold's cost, you must first control the design of your part.

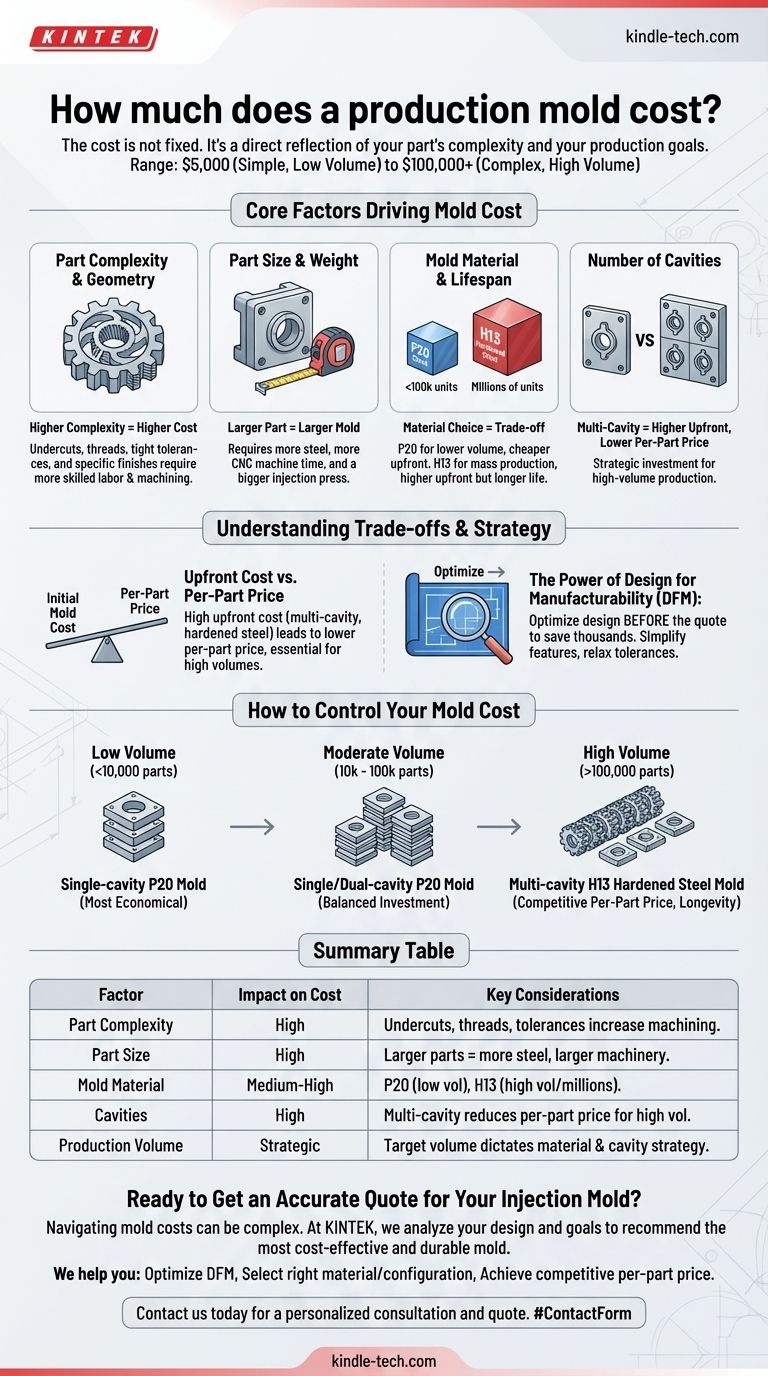

The Core Factors Driving Mold Cost

Understanding what goes into the price of a mold demystifies the cost and gives you the power to influence it. The price is primarily a function of the machinist time and the raw materials required to create a precise, durable tool.

Part Complexity and Geometry

This is the single greatest driver of cost. A simple, open-and-shut box is far cheaper to mold than a component with intricate features.

Factors that dramatically increase complexity and cost include undercuts, which require side-actions or lifters, and threads, which necessitate unscrewing mechanisms. Similarly, tight tolerances and specific surface finishes (like high polish or specific textures) require more precise machining and skilled labor, directly adding to the final price.

Part Size and Weight

A larger part necessitates a larger mold. This has a cascading effect on cost.

A bigger mold requires significantly more steel, which increases material costs. It also requires more time on larger, more expensive CNC machines to cut the steel, and it will ultimately need to run in a larger injection molding press, which has a higher hourly rate.

Mold Material and Lifespan

The type of steel used to construct the mold is chosen based on the desired production volume. This is a fundamental trade-off between upfront cost and long-term durability.

A P20 steel mold is a common, cost-effective choice suitable for volumes up to around 100,000 units. For mass production in the millions, a hardened tool steel like H13 is required. Hardened steel is more expensive and much harder to machine, significantly increasing the mold's upfront cost but ensuring it can withstand the pressures of a long production run.

Number of Cavities

A mold can be designed to produce one part per cycle (a single-cavity mold) or multiple parts per cycle (a multi-cavity mold).

A multi-cavity mold is much more expensive to build because you are essentially creating multiple molds within a single tool base. However, it drastically reduces the per-part price because you produce more units for the same amount of machine time. This is a strategic investment for high-volume products.

Understanding the Trade-offs

Choosing a mold isn't just about finding the lowest price. It's about investing in a tool that matches your specific production requirements. A mismatch here is a common and costly mistake.

The Pitfall of a "Cheap" Mold

A very low-cost quote, often for an aluminum or low-grade steel mold, is typically for a "prototype" or "bridge" tool. While perfect for testing or very small runs (under 5,000 parts), this type of mold will not withstand the rigors of full-scale production. It will wear out quickly, produce inconsistent parts, and ultimately require you to purchase a second, more expensive production tool.

Upfront Cost vs. Per-Part Price

The tension between the mold's initial cost and the final per-part cost is constant. A simple, single-cavity mold has a low entry price but results in a higher per-part cost. A complex, multi-cavity hardened steel mold has a very high initial cost but delivers a much lower per-part cost, which is essential for profitability at high volumes.

The Power of Design for Manufacturability (DFM)

The most effective way to reduce mold cost happens before a quote is ever requested. Design for Manufacturability (DFM) is the process of optimizing your part design to make it easier and more efficient to produce. Eliminating a single unnecessary undercut or relaxing a non-critical tolerance can remove thousands of dollars from the cost of the mold.

How to Control Your Mold Cost

Your production goal is the single most important factor in determining the right investment. Use your target volume as your guide.

- If your primary focus is prototyping or low-volume (<10,000 parts): A single-cavity mold made from P20 steel is the most economical and effective solution.

- If your primary focus is moderate-volume production (10,000 to 100,000 parts): A high-quality, single or dual-cavity P20 steel mold offers the best balance of investment and durability.

- If your primary focus is high-volume mass production (>100,000 parts): Investing in a multi-cavity mold made from hardened tool steel (H13) is necessary to achieve a competitive per-part price and ensure tool longevity.

By understanding the factors that build its cost, you transform the mold from a major expense into a strategic asset for your project.

Summary Table:

| Factor | Impact on Cost | Key Considerations |

|---|---|---|

| Part Complexity | High | Undercuts, threads, and tight tolerances significantly increase machining time and cost. |

| Part Size | High | Larger parts require more steel and larger, more expensive machinery. |

| Mold Material | Medium to High | P20 steel for lower volumes (<100k), hardened H13 steel for high-volume production (millions). |

| Number of Cavities | High | Multi-cavity molds cost more upfront but drastically reduce the per-part price for high volumes. |

| Production Volume | Strategic | Your target volume dictates the optimal mold material and cavity strategy. |

Ready to Get an Accurate Quote for Your Injection Mold?

Navigating mold costs can be complex, but you don't have to do it alone. At KINTEK, we specialize in providing tailored solutions for laboratory equipment and consumables manufacturing. Our experts will analyze your part design and production goals to recommend the most cost-effective and durable mold for your specific needs.

We help you:

- Optimize your design for manufacturability (DFM) to reduce costs.

- Select the right mold material and configuration for your target volume.

- Achieve a competitive per-part price and ensure long-term production success.

Contact us today for a personalized consultation and quote. Let's turn your project into a production reality.

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Special Shape Press Mold for Lab

- Special Heat Press Mold for Lab Use

- Assemble Lab Cylindrical Press Mold

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

People Also Ask

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?

- Is it fitting the mould or mold? A Guide to Correct Spelling by Region

- What is the core function of high-strength graphite molds? Master Vacuum Hot Press Sintering Efficiency

- What are the advantages of using PEEK molds for sulfide all-solid-state batteries? High Performance and Insulation

- How do custom graphite molds contribute to Al-20% Si/graphite flake composites? Optimize Microstructure & Conductivity